High-efficiency electromagnetic reversing pneumatic pump

An electromagnetic reversing and high-efficiency technology, which is applied in the direction of variable capacity pump components, pumps, piston pumps, etc., can solve the problems of lack of production technology and production conditions, high price, and large volume, and achieve convenient processing and maintenance. The effect of low cost and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

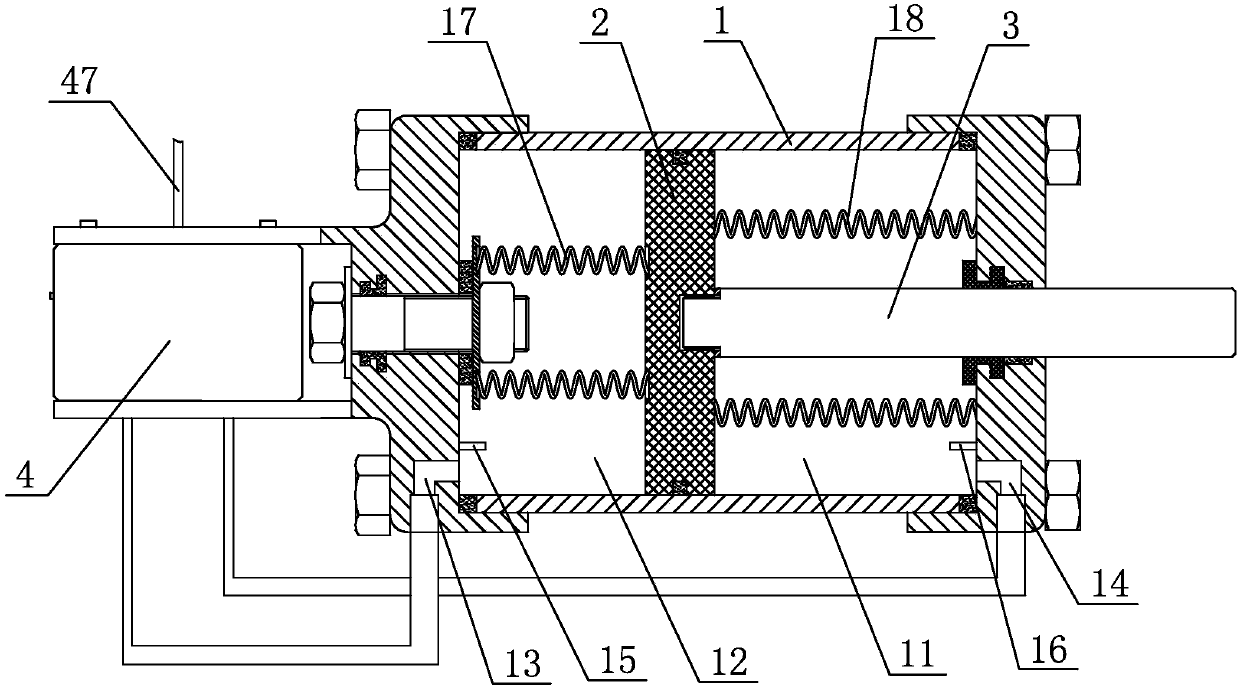

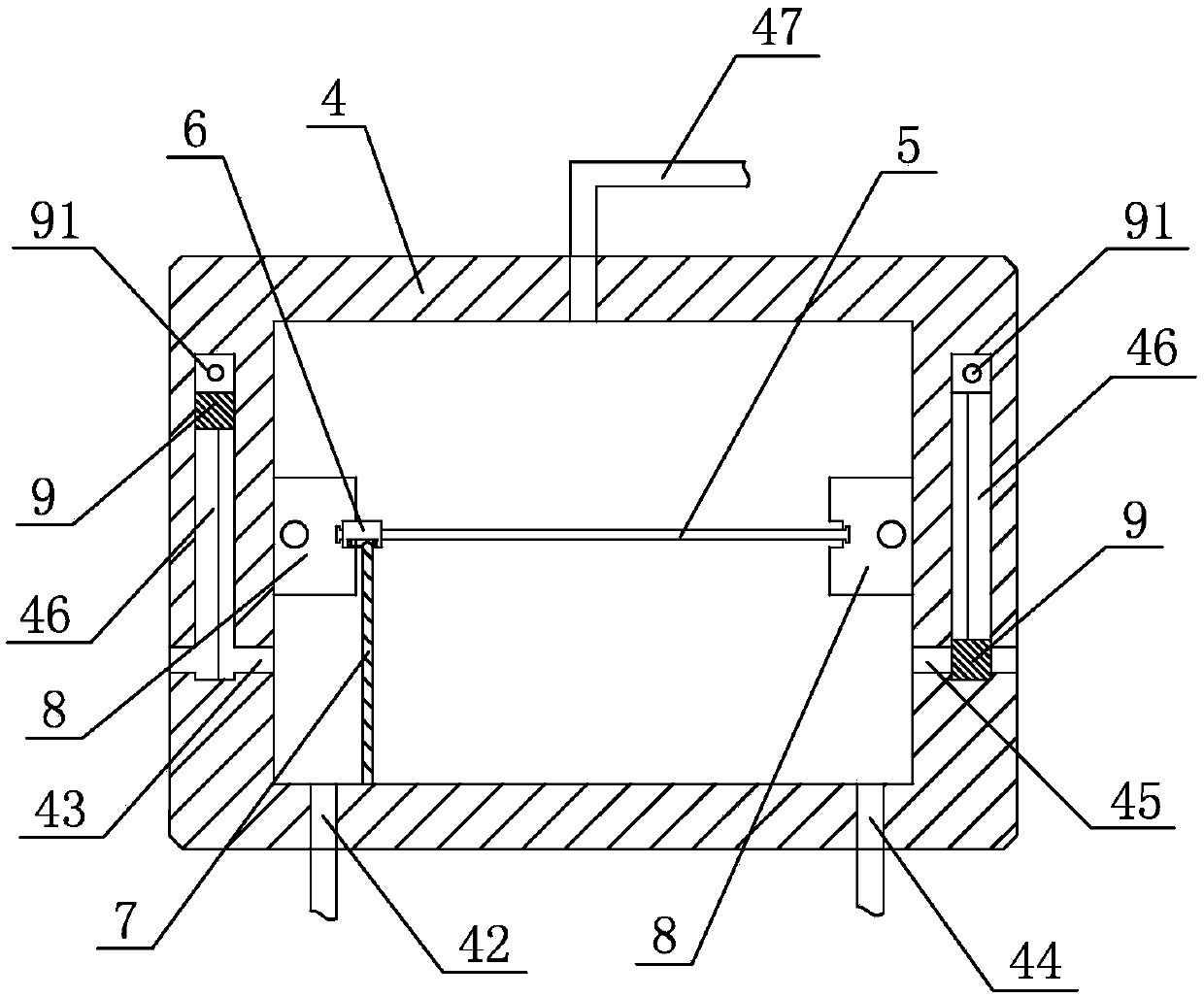

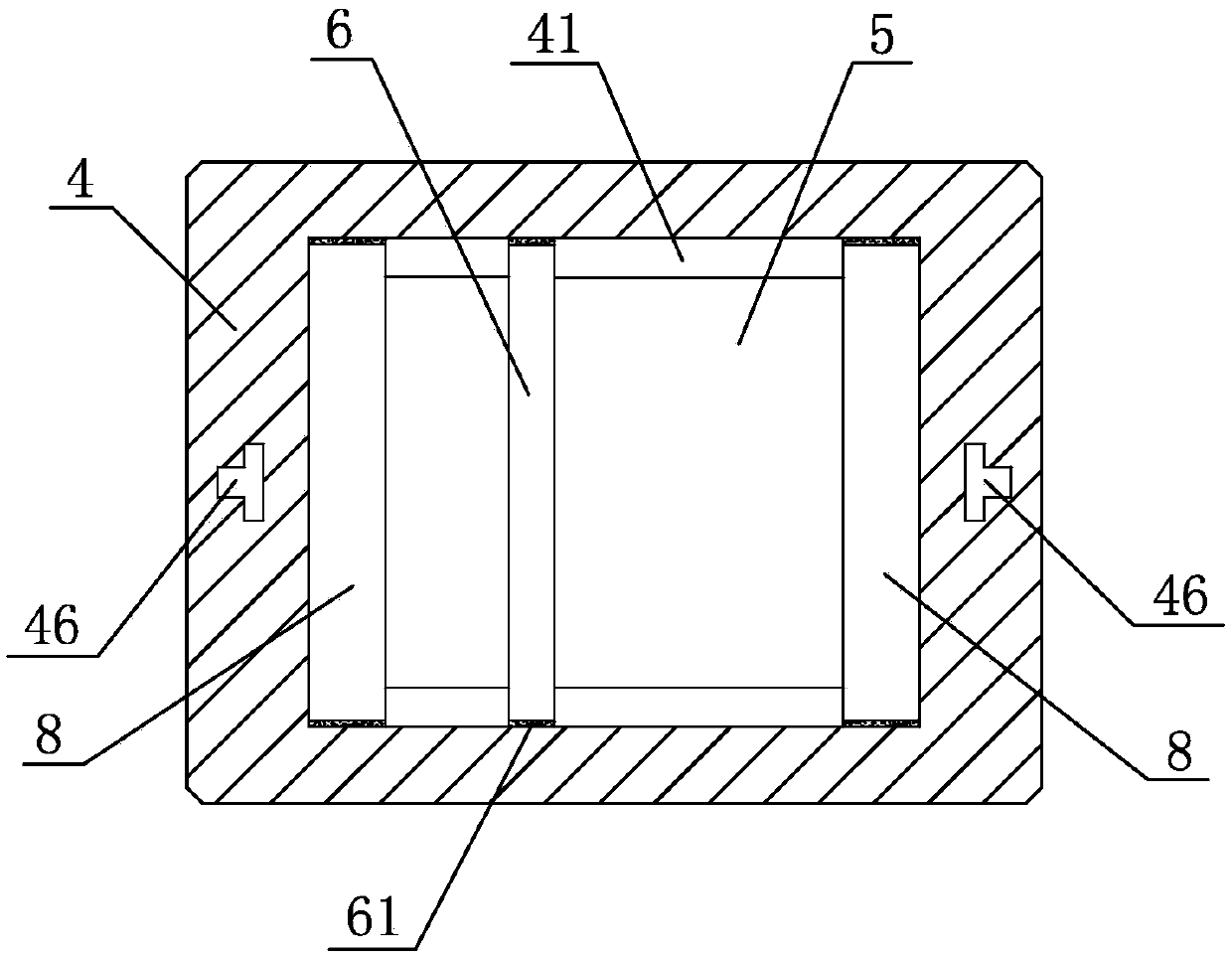

[0017] Embodiment 1: As shown in the figure, a high-efficiency electromagnetic reversing pneumatic pump includes a cylinder block 1, a piston 2 and a piston rod 3. The piston 2 is arranged in the cylinder block 1 and is sealed and slidably matched with the cylinder block 1. The piston 2 divides the inner cavity of the cylinder block 1 into a rod cavity 11 and a rodless cavity 12. The piston rod 3 is coaxially fixed with the piston 2 and passes out of the cylinder block 1 in the axial direction. The wall of the rodless cavity 12 is provided with a second A vent 13, a second vent 14 is arranged on the cavity wall of the rod cavity 11, an electromagnetic reversing mechanism is arranged between the first vent 13 and the second vent 14, and the electromagnetic reversing mechanism includes a casing 4 and The guide rail 5, the slide block 6 and the partition 7 arranged in the box body 4, the left and right ends of the guide rail 5 are respectively fixedly provided with strip electroma...

Embodiment 2

[0019] Embodiment 2: As shown in the figure, other structures are the same as Embodiment 1, and the difference is that the first exhaust hole 43 and the second exhaust hole 45 communicate with the upper part of the guide rail 5 in the box body 4 through the air pipe, A pressure sensor 10 is fixed inside the upper end of the box body 4 , and an air intake switch 48 is arranged on the first air pipe 47 .

[0020] In the above embodiment, the working process of the electromagnetic reversing pneumatic pump is as follows: through the first air pipe 47, the box body 4 is fed with air, and then the long electromagnet 8 located at the left end of the guide rail 5 is energized, and the electromagnet 91 located at the left side is energized. Power on, the strip electromagnet 8 absorbs the slider 6 and moves to the left end of the guide rail 5, while the block 9 on the left side is attracted by the electromagnet 91, and the first exhaust hole 43 is opened. At this time, the compressed gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com