Wood drying device utilizing photo-thermal energy

A technology of wood drying and thermal energy, which is applied in the directions of wood drying, static material dryer, heating to dry solid materials, etc. It can solve the problems of low temperature in the glass room, easy radiation loss, and slow drying speed, etc., and achieve good adjustment of light, Good heat preservation and easy drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

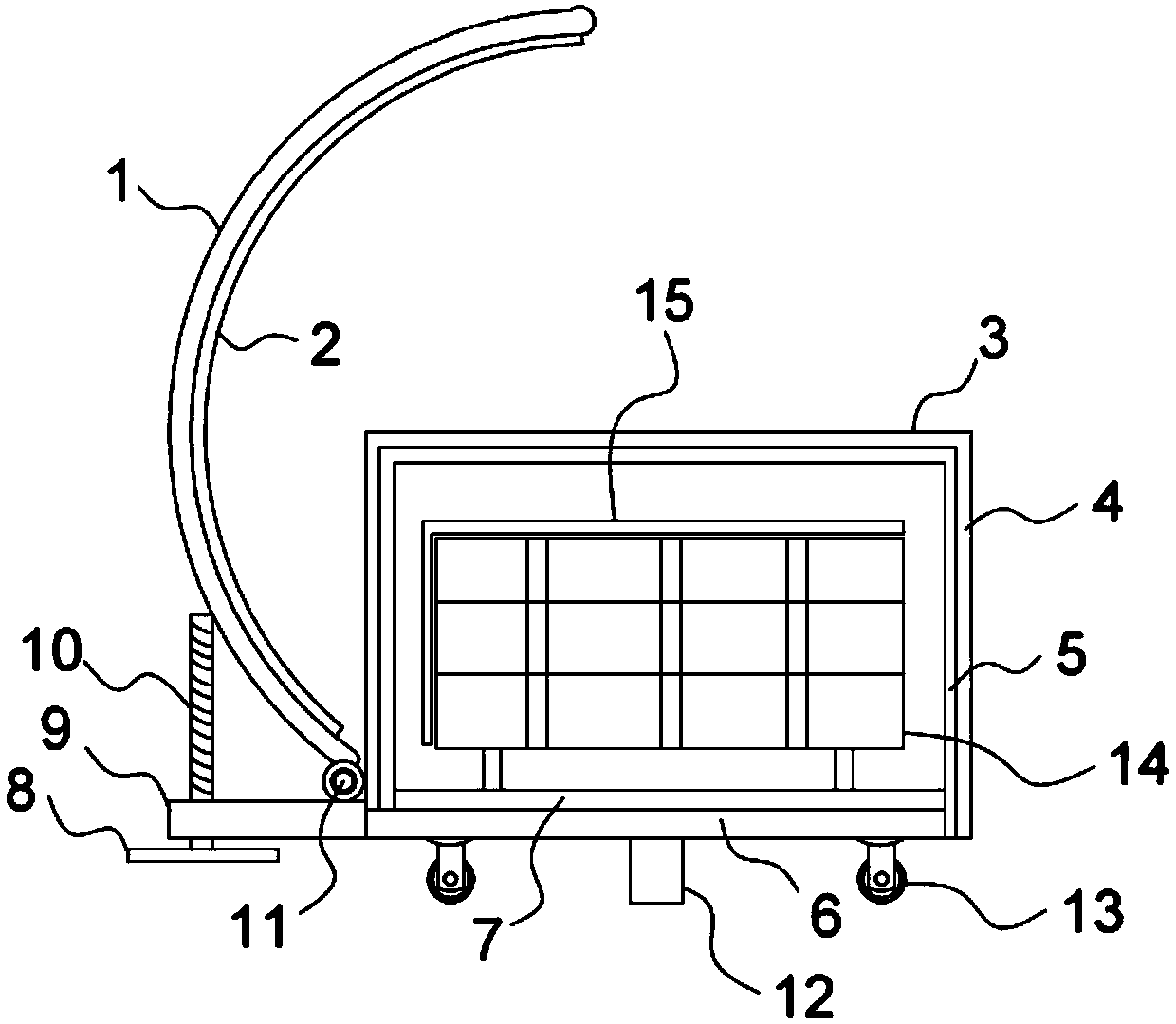

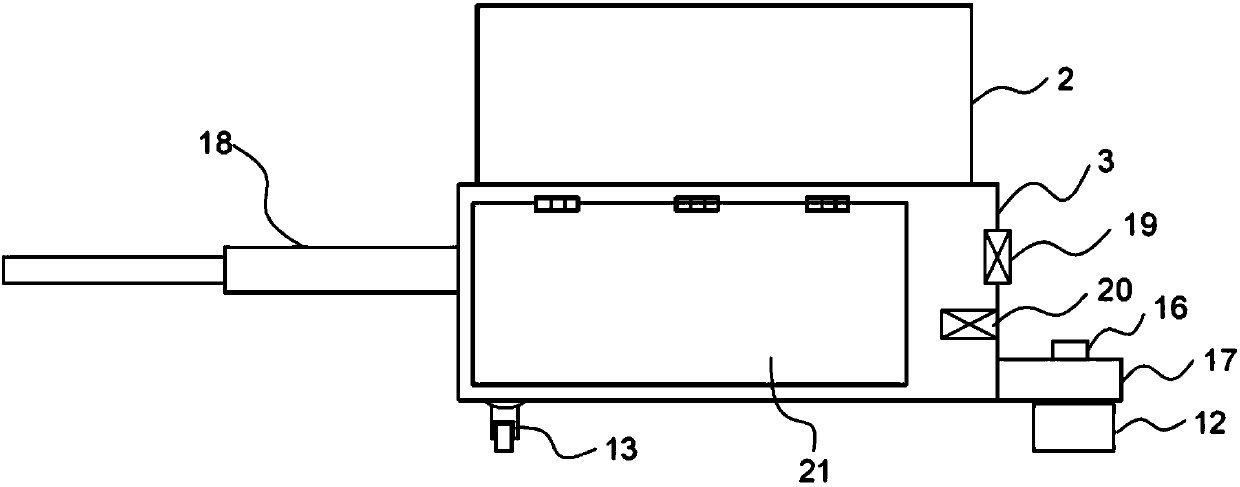

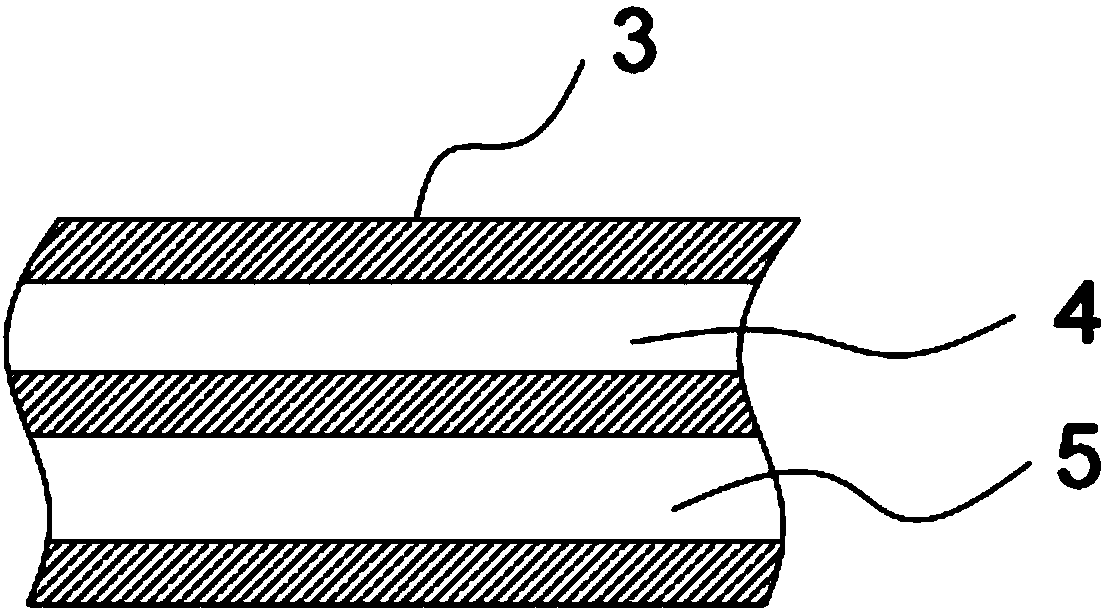

[0031] A wood drying device using light and heat energy, comprising: a transparent glass room 3, which is fixedly installed on a vehicle frame 6, and a support plate 9 is fixedly connected to one side of the vehicle frame 6; an arc-shaped support frame 1, the bottom of which passes through The hinge 11 is hingedly installed on the support plate 9, and one side of the arc support frame 1 is fixedly connected with the arc mirror 2; the screw rod 10 is threaded on the support plate 9 to adjust the height and support the arc support frame The screw rod 10 of 1, the lower end of the screw rod 10 is fixedly connected with the flywheel 8; the timber frame 14, the timber frame 14 is arranged in the transparent glass room 3, and the top of the timber frame 14 is fixedly connected with the sun visor 15; the transparent An internal circulation fan 20 is installed inside the glass house 3 , and a ventilation fan 19 is installed on one side of the transparent glass house 3 , and a transpare...

Embodiment 2

[0034] Different from Embodiment 1, the gases used in the greenhouse gas layer 5 are different, and the details are as follows:

[0035] A wood drying device using light and heat energy, comprising: a transparent glass room 3, which is fixedly installed on a vehicle frame 6, and a support plate 9 is fixedly connected to one side of the vehicle frame 6; an arc-shaped support frame 1, the bottom of which passes through The hinge 11 is hingedly installed on the support plate 9, and one side of the arc support frame 1 is fixedly connected with the arc mirror 2; the screw rod 10 is threaded on the support plate 9 to adjust the height and support the arc support frame The screw rod 10 of 1, the lower end of the screw rod 10 is fixedly connected with the flywheel 8; the timber frame 14, the timber frame 14 is arranged in the transparent glass room 3, and the top of the timber frame 14 is fixedly connected with the sun visor 15; the transparent An internal circulation fan 20 is instal...

Embodiment 3

[0038] The difference from Example 1 is that the charcoal layer 7 is replaced by a moisture-absorbing and heating fiber layer, and the specific content is as follows:

[0039] A wood drying device using light and heat energy, comprising: a transparent glass room 3, which is fixedly installed on a vehicle frame 6, and a support plate 9 is fixedly connected to one side of the vehicle frame 6; an arc-shaped support frame 1, the bottom of which passes through Hinge 11 is hingedly installed on support plate 9, and one side of arc support frame 1 is fixedly connected with arc mirror 2; The screw rod 10 of 1, the lower end of the screw rod 10 is fixedly connected with the flywheel 8; the timber frame 14, the timber frame 14 is arranged in the transparent glass room 3, and the top of the timber frame 14 is fixedly connected with the sun visor 15; the transparent An internal circulation fan 20 is installed inside the glass house 3 , and a ventilation fan 19 is installed on one side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com