A micro-vibration isolator accelerated life test method and system

An accelerated life test, micro-vibration isolator technology, applied in vibration testing, testing of machine/structural components, instruments, etc., can solve problems such as low oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

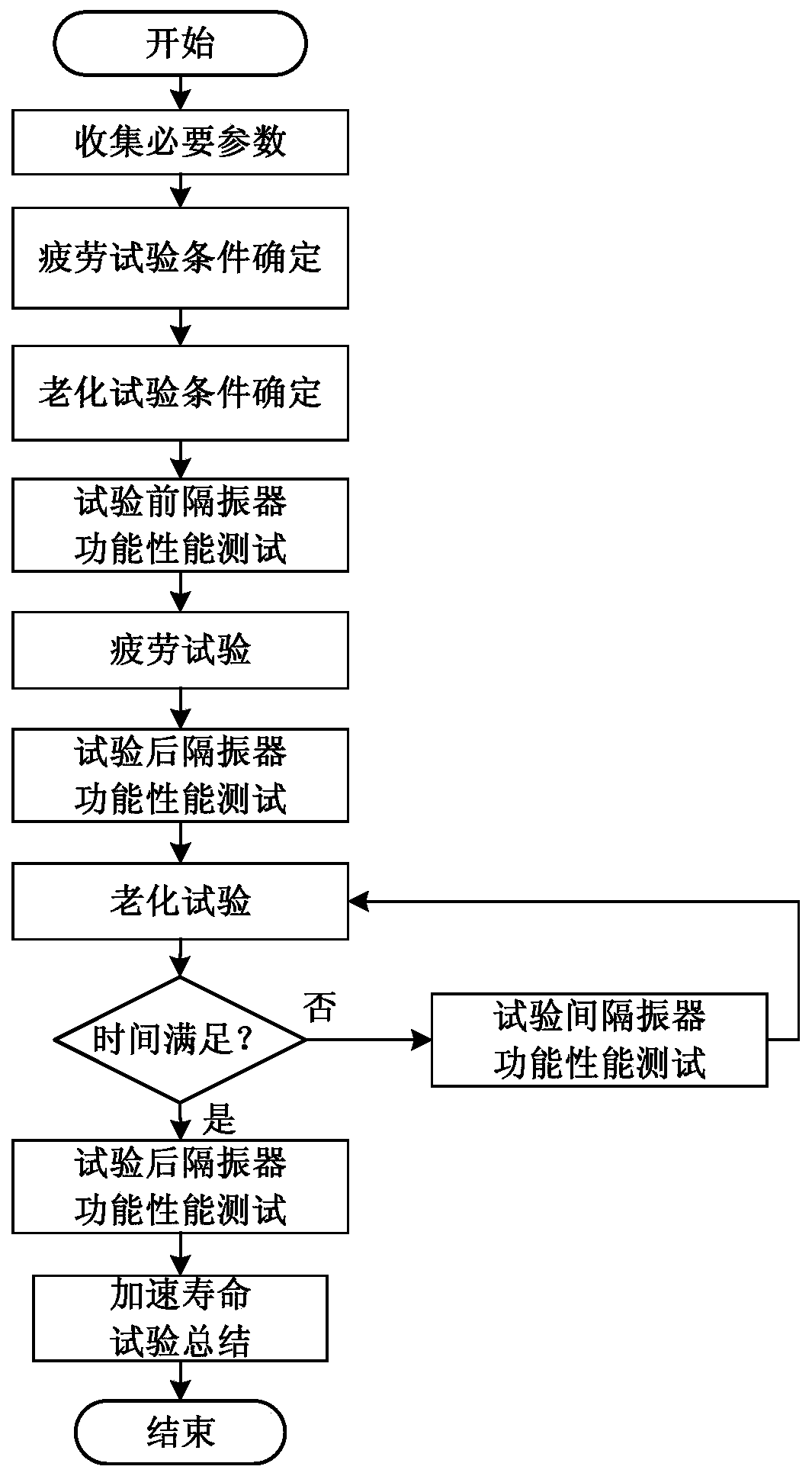

Method used

Image

Examples

Embodiment

[0155] Taking the control moment gyro vibration isolator of a certain satellite as an example to illustrate the specific implementation of the life test.

[0156] (1) Collect the necessary parameters:

[0157] The maximum operating temperature of the vibration isolator is 90°C

[0158] The accelerated time range of the accelerated fatigue test is less than 48h

[0159] Accelerated aging test accelerated time range is less than 45 days

[0160] (2) Determine the conditions for carrying out the accelerated fatigue test:

[0161] The service life of this type of vibration isolator is required to be 8 to 12 years. When working in a space environment, it is subjected to periodic stress with a frequency of 60Hz, 100Hz, 200Hz, 300Hz, etc., and an amplitude of about 0.1mm-0.4mm for a long time.

[0162] Determine the displacement amplitude X that the vibration isolator can bear in normal operation 1 =0.4mm, frequency f 1 = 300Hz and normal working life t 1 =70080h;

[0163] tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com