Microdosing device and automatic microdosing method

A dispensing device and dosing technology, applied in chemical instruments and methods, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve the problem of compromising the persuasiveness of biological experiments, affecting the results of culture or inspection, and reducing the output of devices and efficiency issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention is further illustrated by the following examples and accompanying drawings:

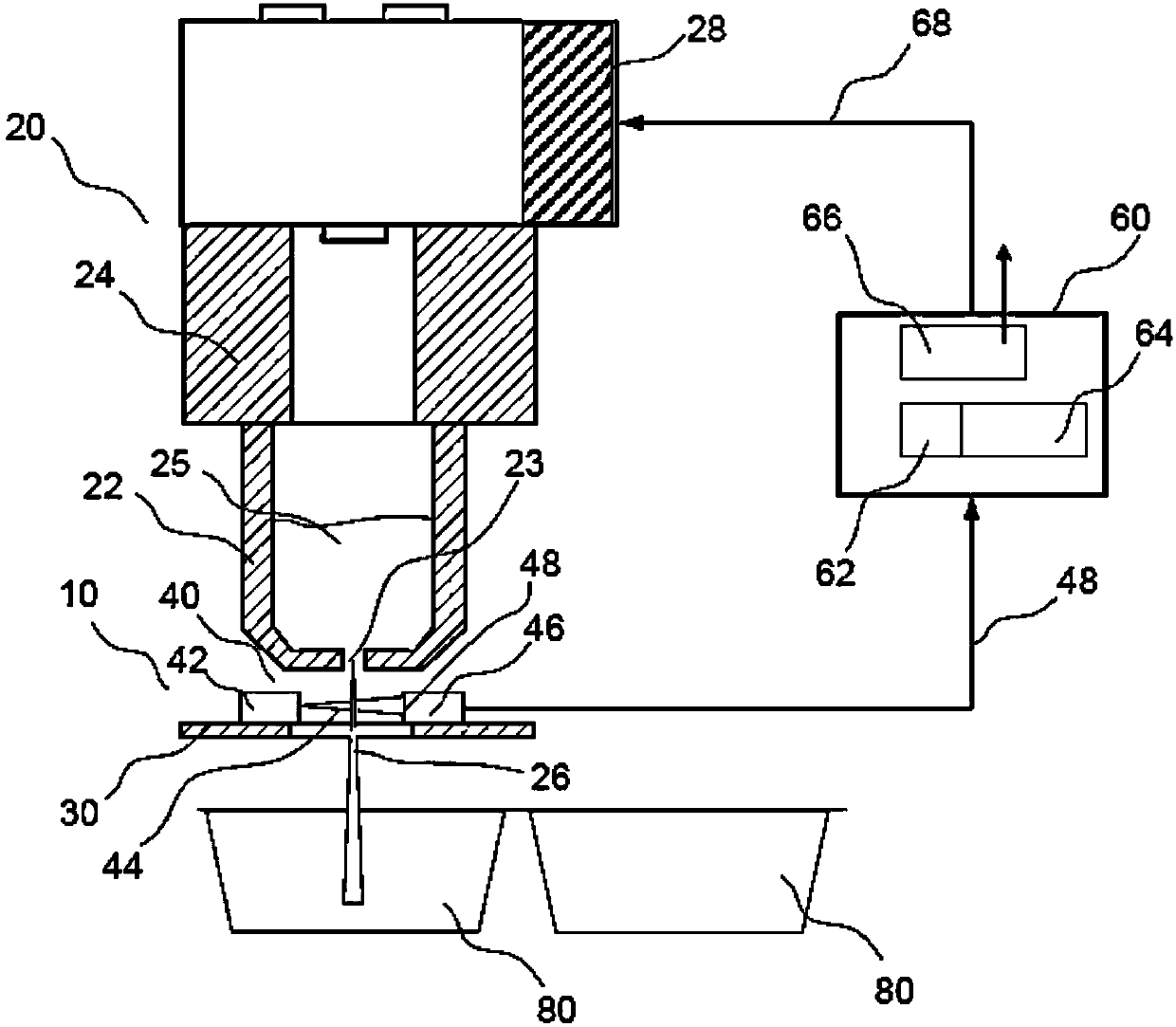

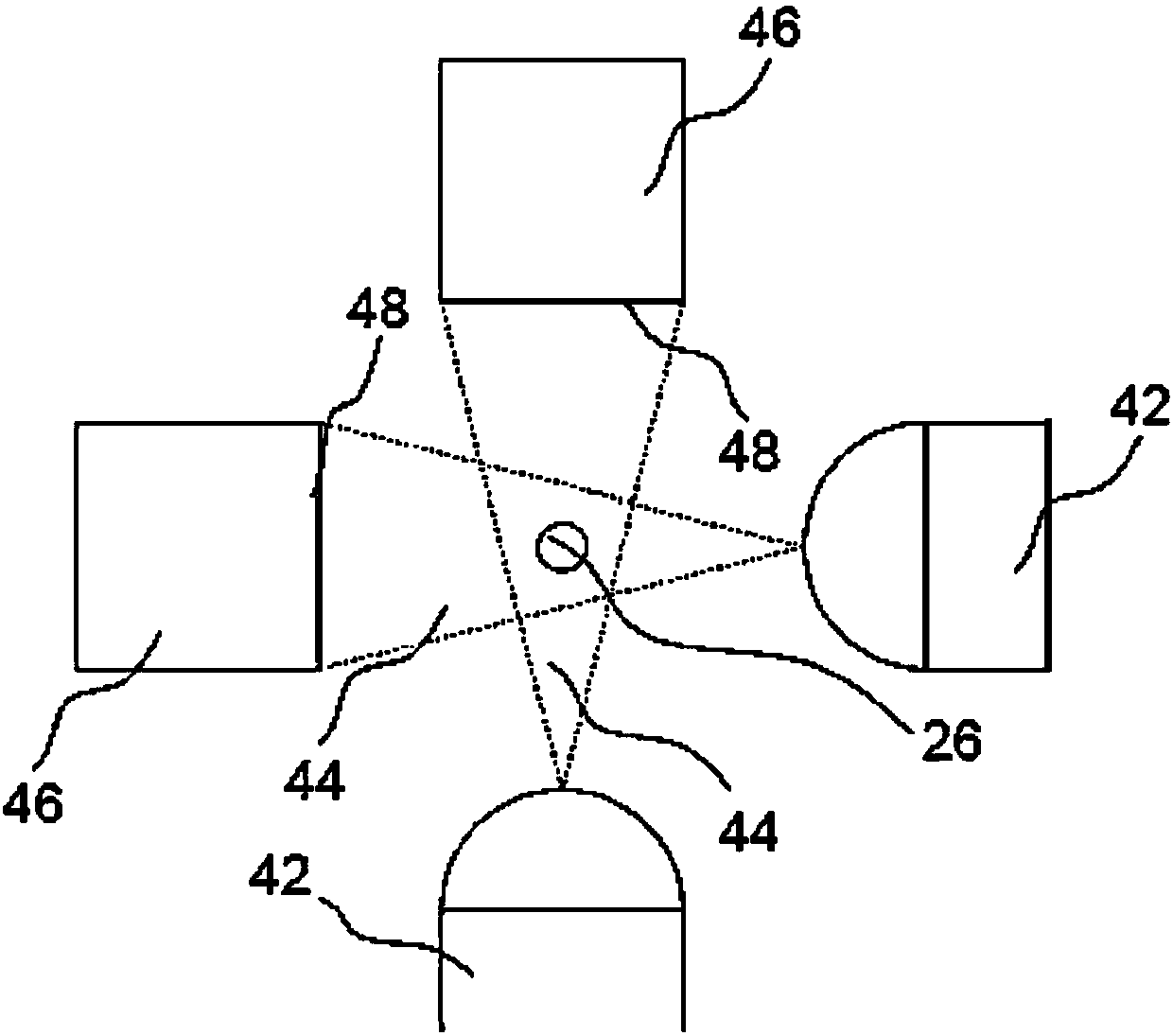

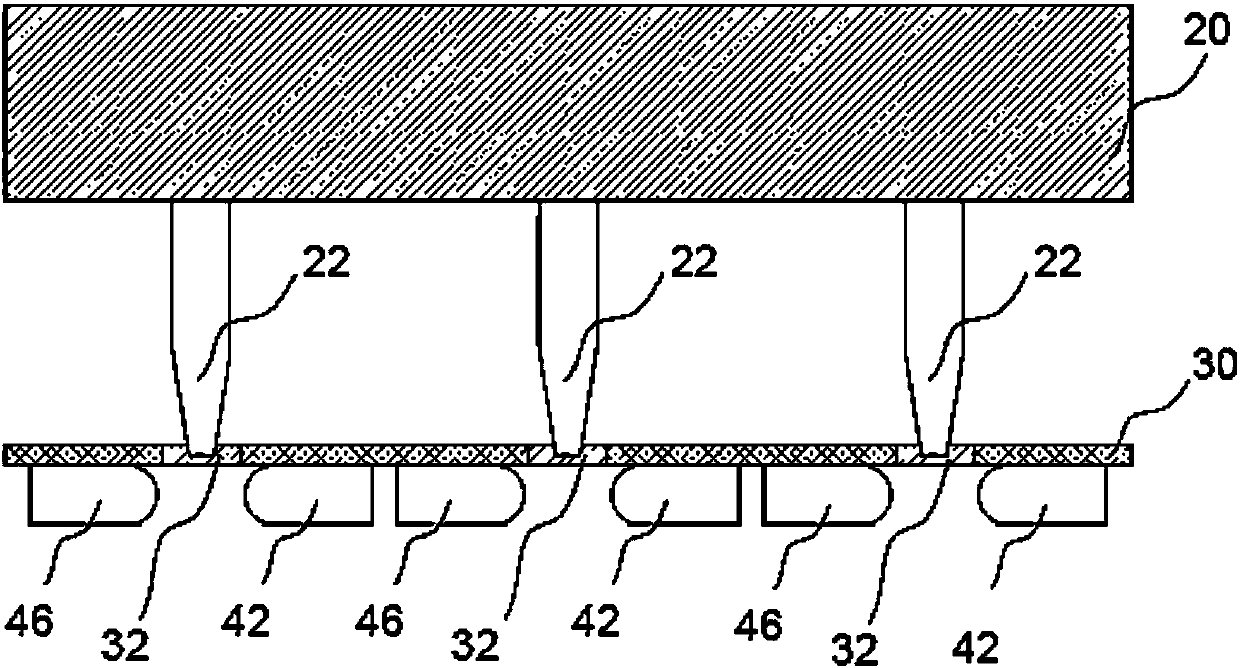

[0056] figure 1 A schematic diagram showing the general structure of the microdispensing device with optical control device of the present invention. For clarity, one of a plurality of dosing channels (English: dosing channel, also called: dosing channel, metering channel, etc.) is shown here. Each metering channel 22 of the micro-dispensing device 20 includes a drive or metering head 24 . The metering head is adapted to apply repeated pressure pulses to the liquid 25 in the metering channel 22 to force the liquid out of the nozzle 23 . The optical device 10 according to the invention is placed directly below the outlet of the metering channel 22 or the nozzle 23 . This essentially consists of a supported light barrier unit 40 with a light source 42 for generating a shaped light beam 44 which is projected onto a sensor surface 48 of a sensor 46 . The light source 42 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com