Spherical graphite and preparation method thereof

A technology of spherical graphite and graphite, which is applied in the field of negative electrode materials, achieves the effects of high molding rate and yield, easy industrialization, and simple and easy methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The invention provides a kind of preparation method of spherical graphite, is characterized in that, comprises the following steps:

[0017] S1, providing graphite raw materials;

[0018] S2, the first grinding of the graphite raw material is carried out in a steam pulverizer with a rotation speed of 3000rpm-5000rpm and rotating clockwise, and then the second grinding is carried out in a steam pulverizer with a rotation speed of 3000rpm-5000rpm and a counterclockwise rotation. Two grinding, and the first grinding and the second grinding are alternately repeated at least twice to obtain potato-shaped graphite particles;

[0019] S3, performing the first shaping treatment on the potato-shaped graphite particles in a shaping machine with a square grinding block medium at a speed of 1000rpm-4000rpm and rotating clockwise, and then placing a cylindrical grinding block medium at a speed of 500rpm-3000rpm The second shaping treatment is carried out in a shaping machine that r...

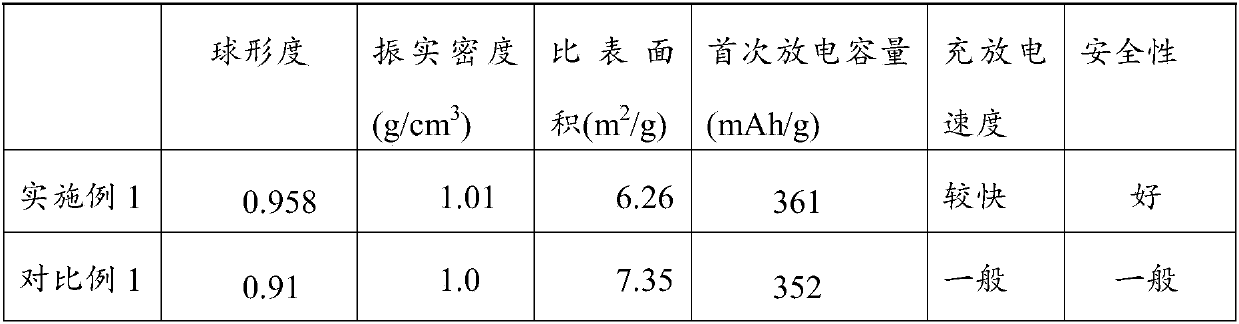

Embodiment 1

[0036] Get 500kg specification and be the natural flake graphite of -195 purpose.

[0037]The natural flake graphite was added to a jet mill rotating clockwise at a speed of 5000rpm for initial grinding for 20 minutes, and then entered into a jet mill rotating counterclockwise for 20 minutes at the same speed. The grinding was repeated twice alternately to obtain potato-shaped graphite particles.

[0038] The potato-shaped graphite particles are rotated clockwise in a shaping machine with a square grinding block medium and the first shaping treatment is performed at a speed of 3000rpm for 40 minutes, and then put into a shaping machine with a cylindrical grinding block medium to rotate counterclockwise And the second shaping is carried out for 40 minutes at the rotating speed of 3000rpm. At this time, the potato-shaped graphite particles gradually tend to be spherical after being finely shaped, and a preform is obtained.

[0039] Carry out continuous classification to the pre...

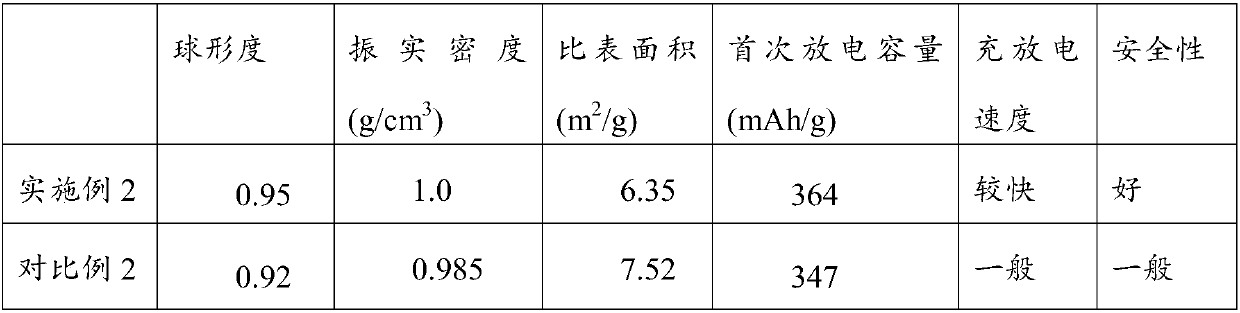

Embodiment 2

[0056] Get 300kg of natural flake graphite whose specification is +1594.

[0057] The natural flake graphite is added into a steam pulverizer rotating clockwise at a speed of 3800rpm for initial grinding for 30 minutes, and then entered into a jet pulverizer rotating counterclockwise to grind for 30 minutes at the same speed to obtain potato-shaped graphite particles.

[0058] The potato-shaped graphite particles are rotated clockwise in a shaping machine with a square grinding block medium and the first shaping treatment is performed at a speed of 3200rpm for 38 minutes, and then put into a shaping machine with a cylindrical grinding block medium to rotate counterclockwise And the second shaping is carried out for 38 minutes at a rotating speed of 3200rpm. At this time, the potato-shaped graphite particles gradually tend to be spherical after being finely shaped, and a preform is obtained.

[0059] Carry out continuous classification to the preform, that is to say, the prefor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com