Metal organic framework material as well as preparation method and application thereof

A metal-organic framework, organic ligand technology, applied in separation methods, alkali metal compounds, chemical instruments and methods, etc., can solve the problems of poor constraint, excessive pore narrowing, excessive interpenetration, etc., to enhance the stability of the framework. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

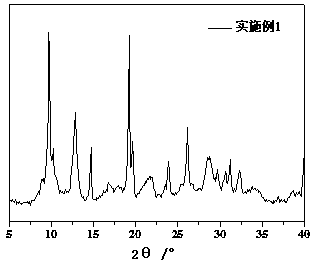

Embodiment 1

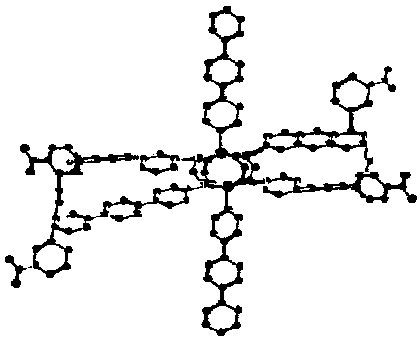

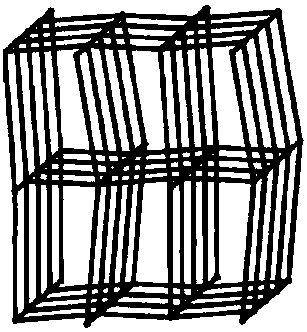

[0045] Weigh 40mgZn(NO 3 ) 2 ·6H 2 O, 20 mg of organic ligand 2',3'-dimethyl-p-terphenyl-4,4''-dicarboxylic acid, 15 mg of auxiliary organic ligand 1,4-bis(p-pyridyl)benzene, then dissolved in 2.84g DMF ( N,N' -dimethylformamide), placed in a stainless steel reaction kettle lined with polytetrafluoroethylene, and the thermal synthesis reaction was carried out at 85 °C for 72 h. Subsequently, the temperature was lowered to room temperature at a rate of 1°C / min, the kettle was opened, and the solution containing the colorless massive crystals was subjected to suction filtration treatment, and then washed with DMF and acetone respectively. After drying at ℃ for 30 h, metal organic framework material A was obtained. Among them, along the crystal a-axis direction of the metal-organic framework material A, the size of the main channel is 14.23 Å × 13.05 Å.

Embodiment 2

[0047] 40mgZn(NO 3 ) 2 ·6H 2 O was replaced by 31mgCu(NO 3 ) 2 ·3H 2 O, the thermal synthesis reaction temperature was increased to 100°C, the thermal synthesis reaction time was shortened to 48h, and other reaction conditions and material compositions were the same as in Example 1, to obtain metal organic framework material B.

Embodiment 3

[0049] 15mg auxiliary organic ligand 1,4-bis(p-pyridyl)benzene was replaced with 9.36mg 4,4'-bipyridine, and the cooling rate was increased to 3°C / min. Other reaction conditions and material compositions were the same as in Example 1, , the metal-organic framework material C was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com