Nanocomposite material possessing two-dimensional pore passage structure and its preparation method

A nanocomposite material and pore structure technology are applied in the field of nanocomposite materials with a two-dimensional cubic p6m pore structure and their preparation, achieving the effects of economical rationality, strong operability, and avoiding the sol-gel process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0037] The preparation of embodiment 2As-made sample

[0038] Dissolve 2.0g of PEO-PDMS-PEO in 38.0g of THF and stir at 40°C for 10min to obtain a transparent solution. Then add 5.0 g of 20 wt % THF solution of phenolic resin prepolymer, and stir for 0.5 h to obtain a uniform solution. Transfer the solution to a petri dish, volatilize THF at room temperature for 5-8 hours, and then place the petri dish in an oven at 100°C for 24 hours to obtain a transparent orange-yellow film material. The material was scraped off the Petri dish and ground to a powder to obtain an As-made sample (the original untreated sample).

[0039] The PEO-PDMS-PEO in this embodiment is EO 60 -DMS 90 -EO 60 (M w =11940), purchased from Wacker Chemie Co., Ltd., Germany, and was not further processed before use.

Embodiment 3 2

[0040] Example 3 Preparation of two-dimensional ordered mesoporous polymer / silicon oxide and carbon / silicon oxide nanocomposites

[0041] Put the above-mentioned As-made intermediate in a tube furnace for roasting under the protection of nitrogen gas, roast at 350°C for 3 hours to obtain a two-dimensional ordered mesoporous polymer / silicon oxide nanocomposite, and roast at 900°C for 2 hours to obtain a two-dimensional organic Sequenced mesoporous carbon / silicon oxide nanocomposites; during the firing process, when the temperature is below 600°C, the heating rate is set to 1°C / min, and when the temperature is above 600°C, the heating rate is set to 5°C / min. The sample obtained by roasting at 350°C under nitrogen atmosphere is marked as MP-CS-350N, and the sample obtained by roasting at 900°C under nitrogen atmosphere is marked as MP-CS-900N.

[0042] Embodiments 1, 2, and 3 are the preferred solutions of the present invention. In addition, the types of materials, dosage ratio...

Embodiment 4

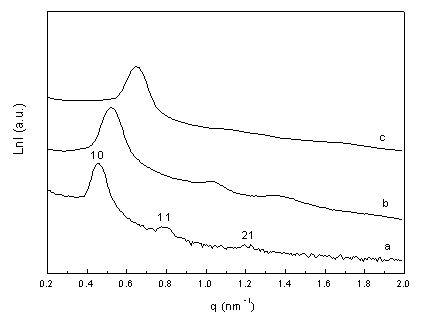

[0043] Example 4 The small-angle X-ray scattering (SAXS) measurement was carried out on the obtained sample by Nanostar U small-angle X-ray scattering instrument (CuKα) from Bruker, Germany. The tube pressure was 40kV, the tube flow was 35mA, and the recording time was 30min. The resulting SAXS as figure 1 shown. Depend on figure 1 It can be seen that three clear diffraction peaks appear on the SAXS spectrum of the As-made sample, corresponding to the diffraction peaks of the 10, 11 and 20 crystal planes of the two-dimensional hexagonal p6m structure, and the q value ratio of the three diffraction peaks is The mesoporous polymer / silicon oxide nanocomposite material was obtained by roasting at 350°C under an inert atmosphere of nitrogen. The mesoscopic structure of the degree is preserved. Calculated from the SAXS spectrum, the unit cell parameters of the nanocomposite before and after calcination are 15.8 and 14.0nm respectively, indicating that the skeleton shrinks by 11....

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com