PBT reclaimed material and preparation method thereof

A technology of recycled materials and recycled materials, applied in the field of plastic products, can solve the problems of warping, longitudinal and transverse shrinkage, etc., and achieve the effect of improving quality, improving curl resistance, and ensuring high temperature curl resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

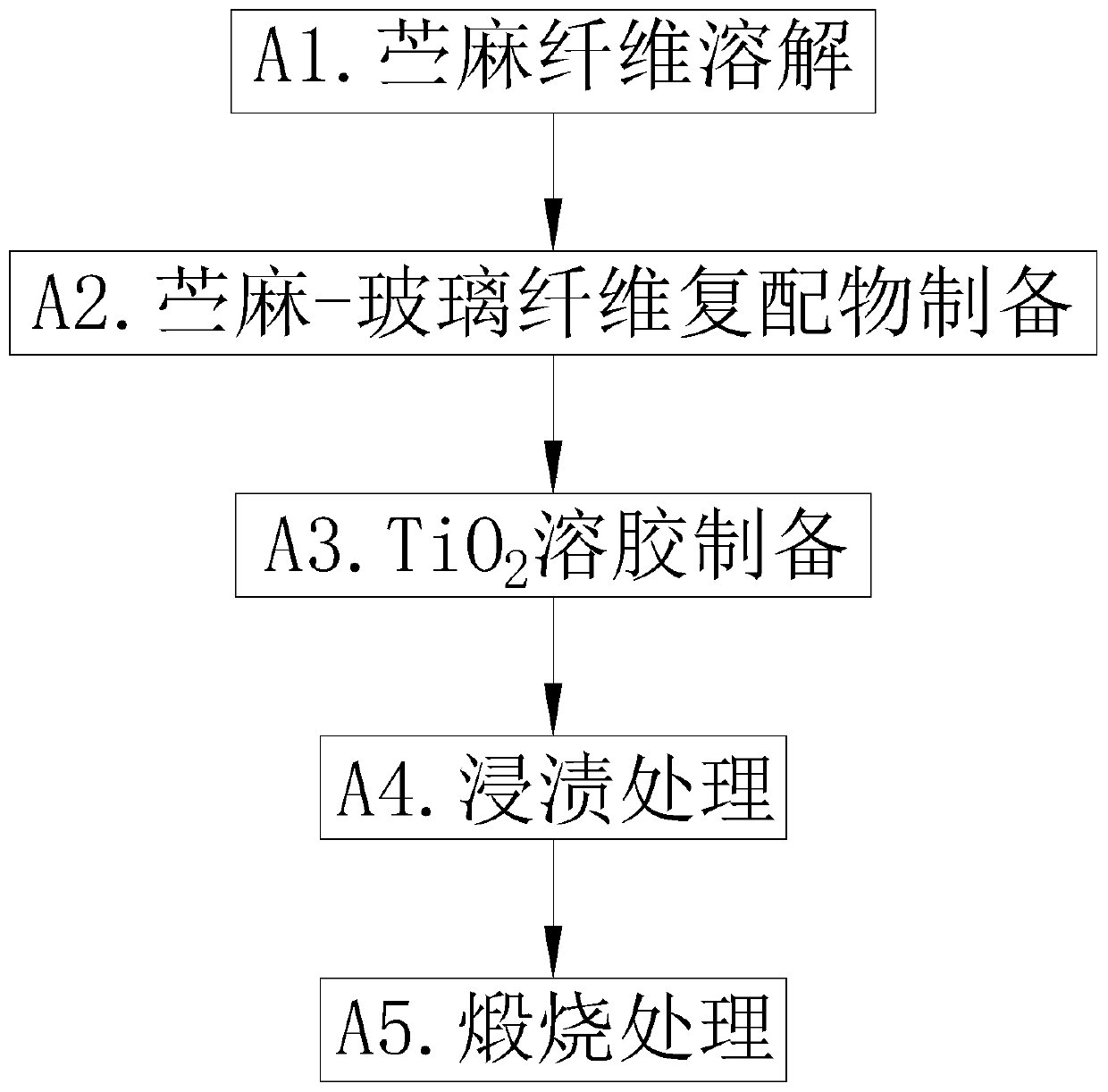

[0043] Embodiment 1, is a kind of PBT regenerated material disclosed by the present invention and preparation method thereof, PBT regenerated material comprises the following components by mass fraction:

[0044]

[0045] Glass fiber / TiO 2 The ratio of / ramie fiber is (0.3-0.5): (0.2-0.4): (0.2-0.4);

[0046] The filler includes heavy calcium carbonate and hollow glass microspheres with a mass fraction of 1: (0.3-0.6);

[0047] The flame retardant includes triphenyl phosphate and decabromodiphenylethane with a mass fraction of 1: (0.5-1.5);

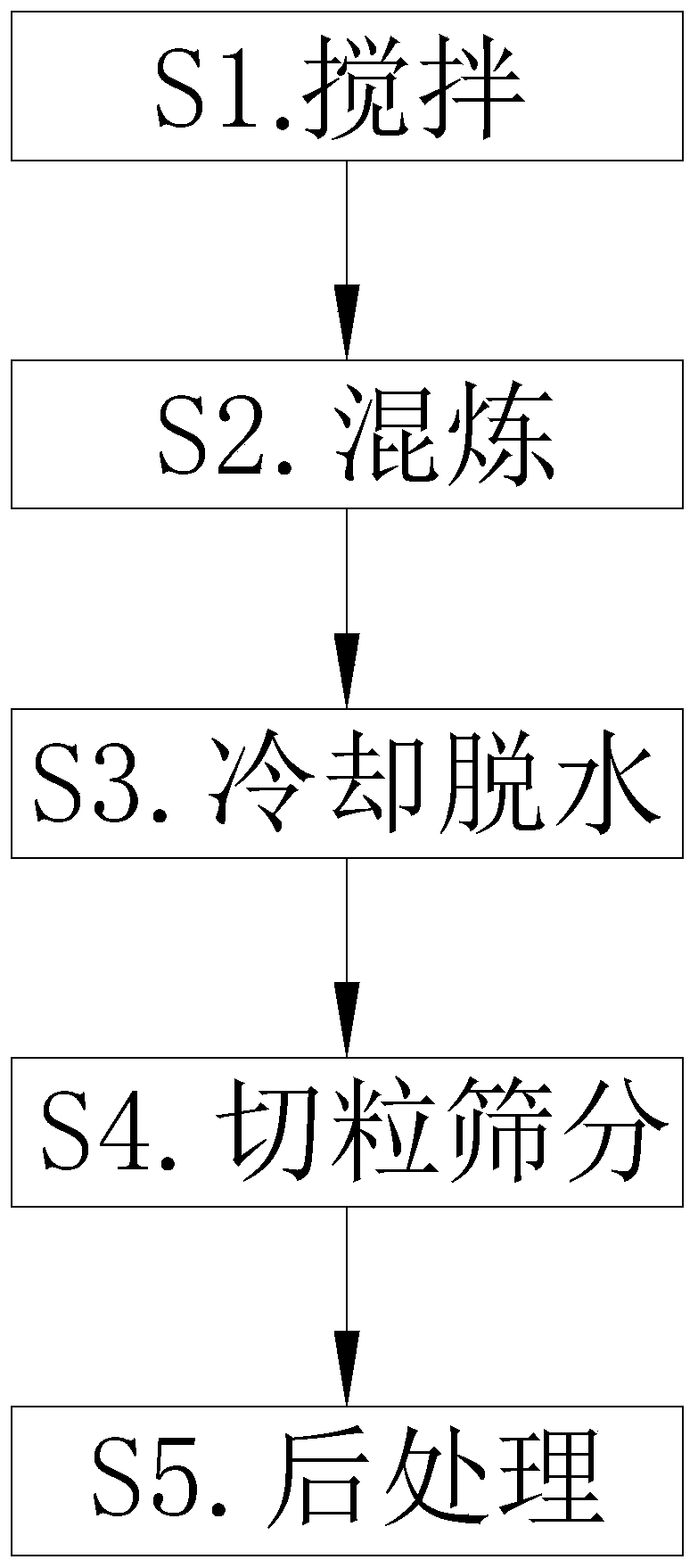

[0048] Glass fiber / TiO 2 The preparation method of ramie fiber is:

[0049] A1. Dissolving ramie fiber: add 20g of anhydrous zinc chloride and 68g of anhydrous formic acid to prepare 100g of formic acid-zinc chloride solution, add ramie fiber into it, stir evenly, and dissolve it;

[0050] A2. Preparation of ramie-glass fiber compound: add glass fiber to formic acid-zinc chloride solution and stir evenly, send the mixed solution to ...

Embodiment 2

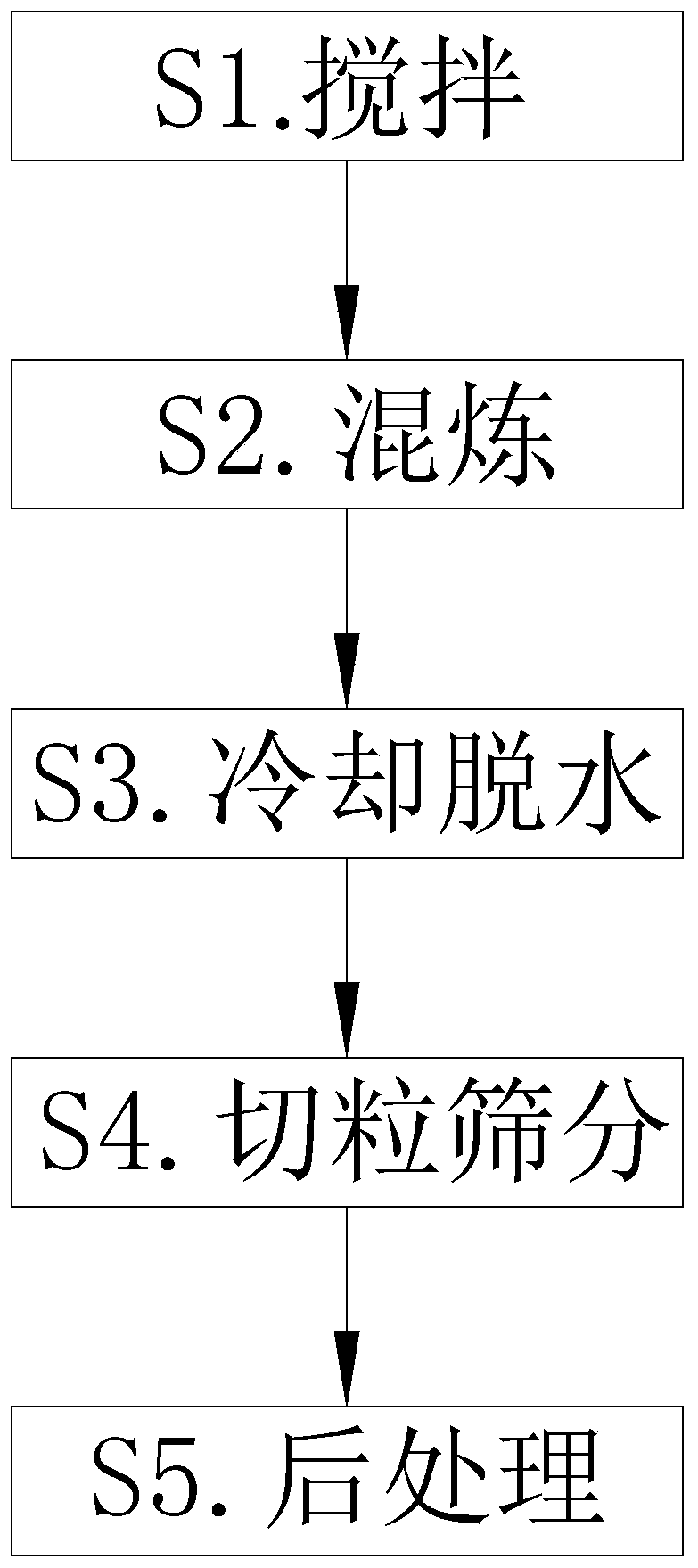

[0060] Embodiment 2, is a kind of PBT regenerated material disclosed by the present invention and preparation method thereof, PBT regenerated material comprises the following components by mass fraction:

[0061]

[0062] Glass fiber / TiO 2 The ratio of / ramie fiber is 0.4:0.3:0.3;

[0063] Glass fiber / TiO 2 The preparation method of / ramie fiber is with embodiment 1;

[0064] The preparation method of PBT regenerated material is with embodiment 1.

Embodiment 3

[0065] Embodiment 3, is a kind of PBT regenerated material disclosed by the present invention and preparation method thereof, PBT regenerated material comprises the following components by mass fraction:

[0066]

[0067]

[0068] Glass fiber / TiO 2 The ratio of / ramie fiber is 0.4:0.3:0.3;

[0069] Glass fiber / TiO 2 The preparation method of / ramie fiber is with embodiment 1;

[0070] The preparation method of PBT regenerated material is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com