Gun cabinet frame welding robot fixture

A welding robot and frame technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of reducing production efficiency, complicated fixture processing and manufacturing process, waste of raw materials, etc., to reduce processing and production costs, The clamping method is scientific and reasonable, and the effect of reducing the labor intensity of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the technical solutions of the present invention, the present invention will be further described by the following embodiments in conjunction with the accompanying drawings.

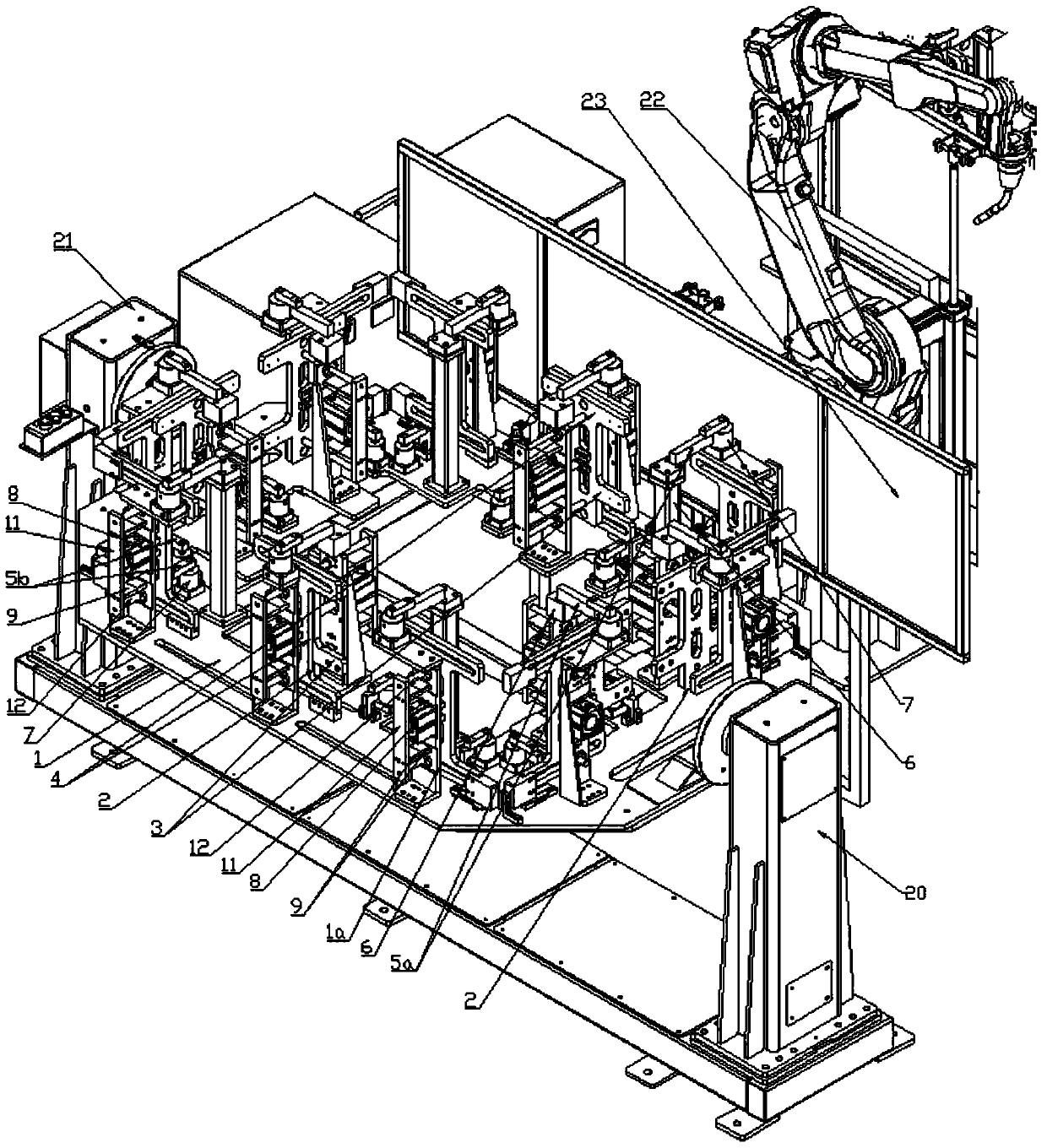

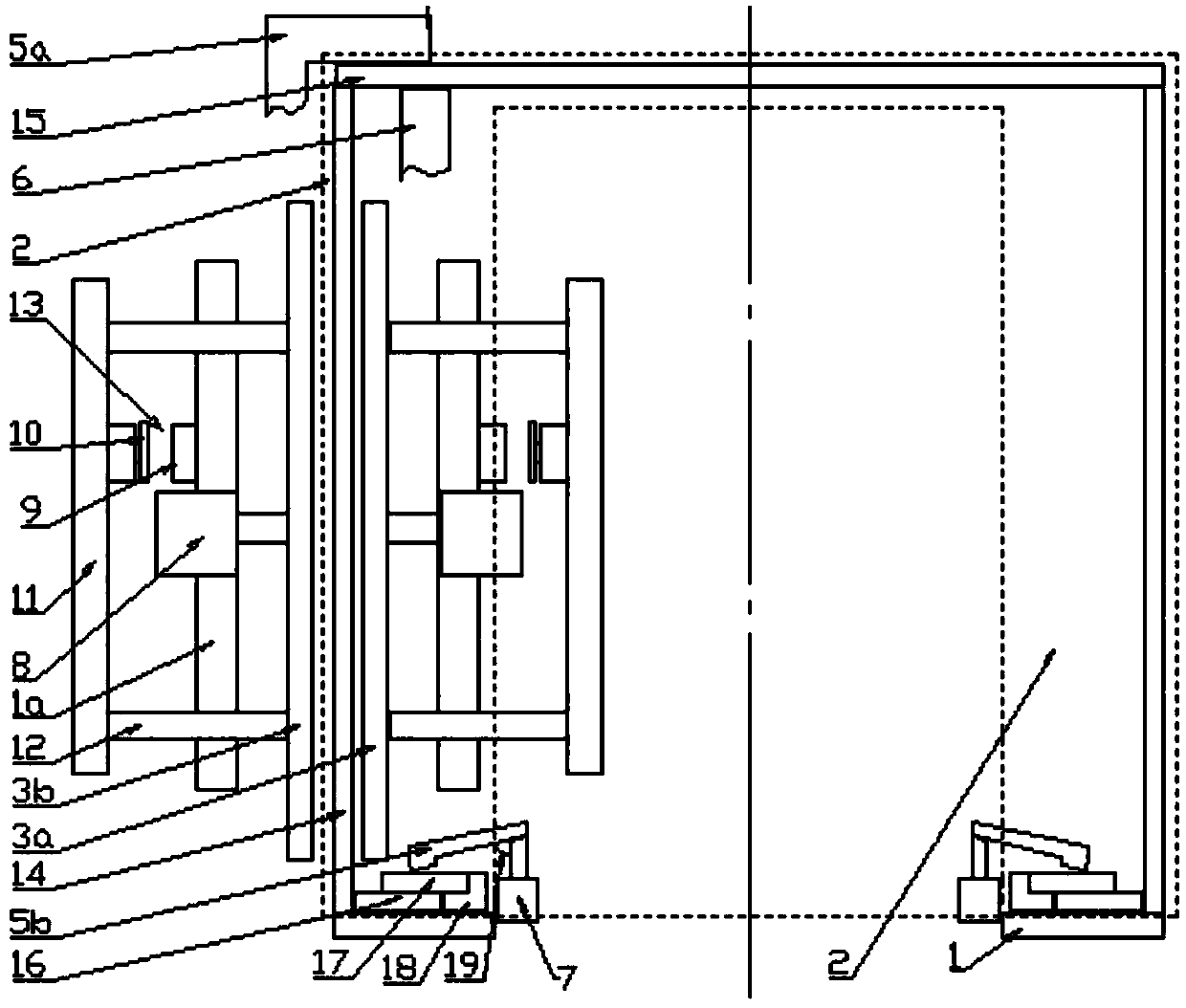

[0019] like figure 1 As shown, the gun cabinet frame welding robot fixture of this embodiment includes a workbench 1, and a frame-type three-dimensional accommodation channel 2 corresponding to the corresponding workpiece, which are respectively arranged on the opposite sides of the frame-type three-dimensional accommodation channel. The internal and external variable clamping devices corresponding to the corresponding workpieces, etc. The workbench 1 is a frame-type rotatable workbench suspended in the air through the corresponding active support column 20 and passive support column 21, and the surrounding frame walls of the frame-type rotatable workbench constitute the corresponding workpiece of the frame-type three-dimensional accommodation channel. the supportin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com