Preparation method of electronic equipment liquid cooling pipe assembly

A technology of electronic equipment and liquid-cooled tubes, which is applied in the field of preparation of buckle-type pipeline components, can solve problems such as low production efficiency, difficulty in ensuring dimensional accuracy, and welding defects, and achieve low assembly man-hours, good assembly adaptability, and high-quality products. good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

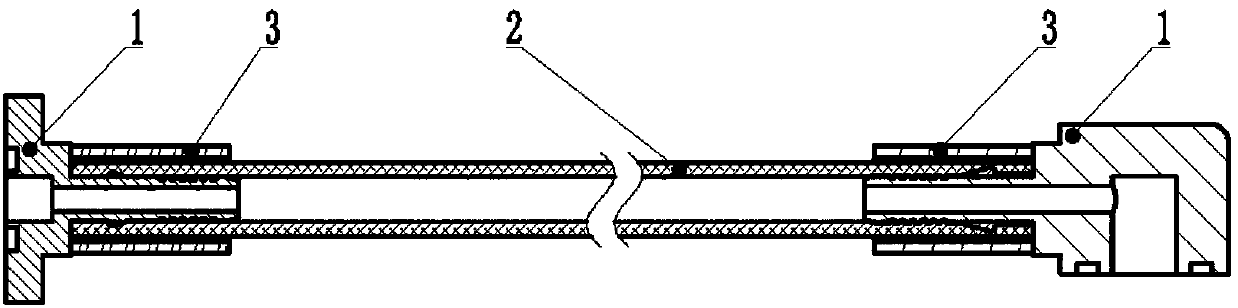

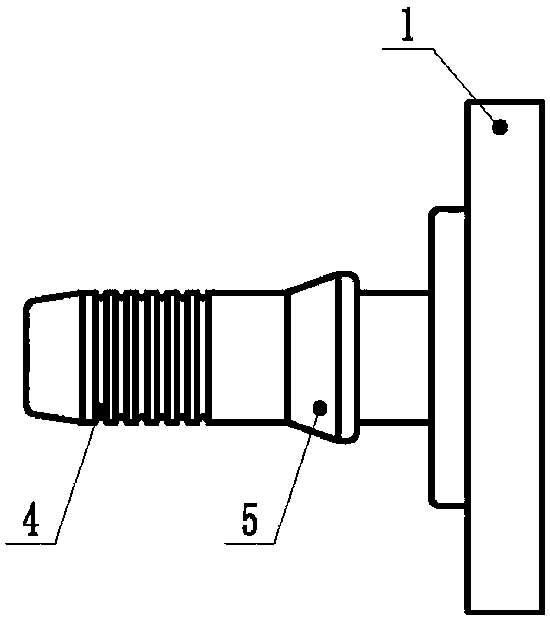

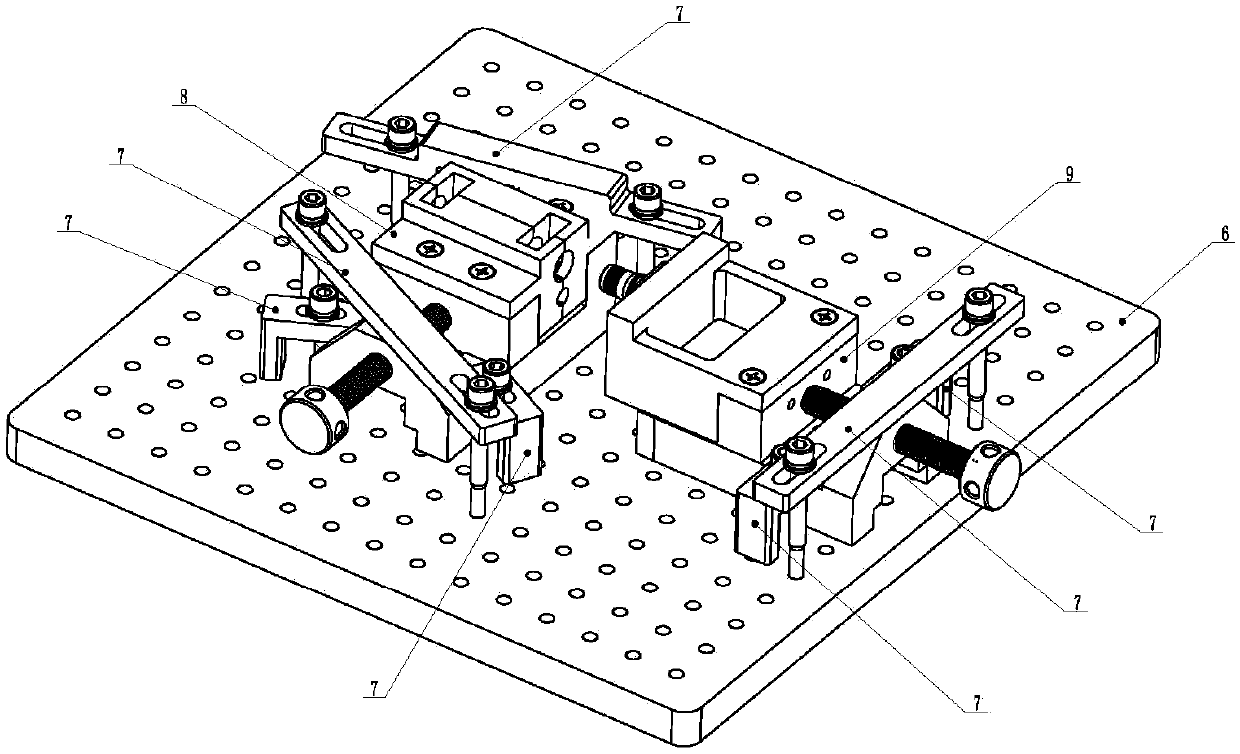

[0021] refer to figure 1 . According to the present invention, the stainless steel braided non-metallic hose 2 is used as the heat exchange flow channel, and the two ends of the non-metallic hose 2 are respectively inserted into the austenitic stainless steel-based sleeve 3, and the anti-rust aluminum-based pipe joints 1 fixedly connected at both ends are connected. On the end face of the tower-type step shaft, the three are integrated by mechanical crimping. During the preparation process, the wall thickness compression rate of the non-metallic hose 2 in the straight section of the arc-shaped groove of the pipe joint 1 is set to 40%-50%. 2 and sleeve 3 in the butt joint size of the assembly part, calculate the withholding amount of the non-metallic hose and pipe joint 1 in the straight section of the arc-shaped groove of the pipe joint 1, set the withholding parameters corresponding to the withholding equipment according to the withholding amount, and use the withholding To...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com