Response-surface-method based enzyme extraction method and content determination of Chinese violet apigenin

A viola chinensis, response surface method technology, applied in the direction of measuring devices, instruments, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] (1) drying and pulverizing Viola Viola into 80 meshes to obtain Viola Viola powder;

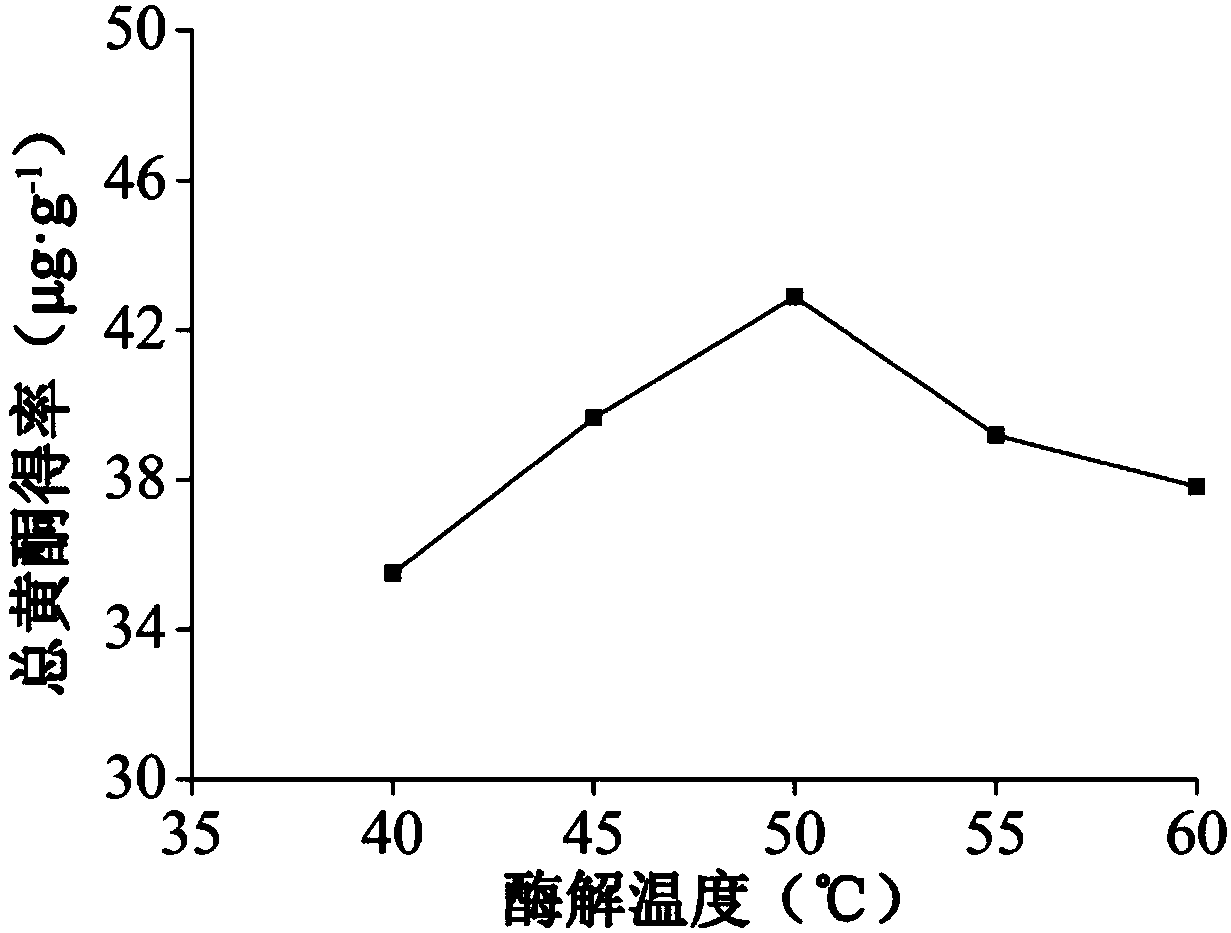

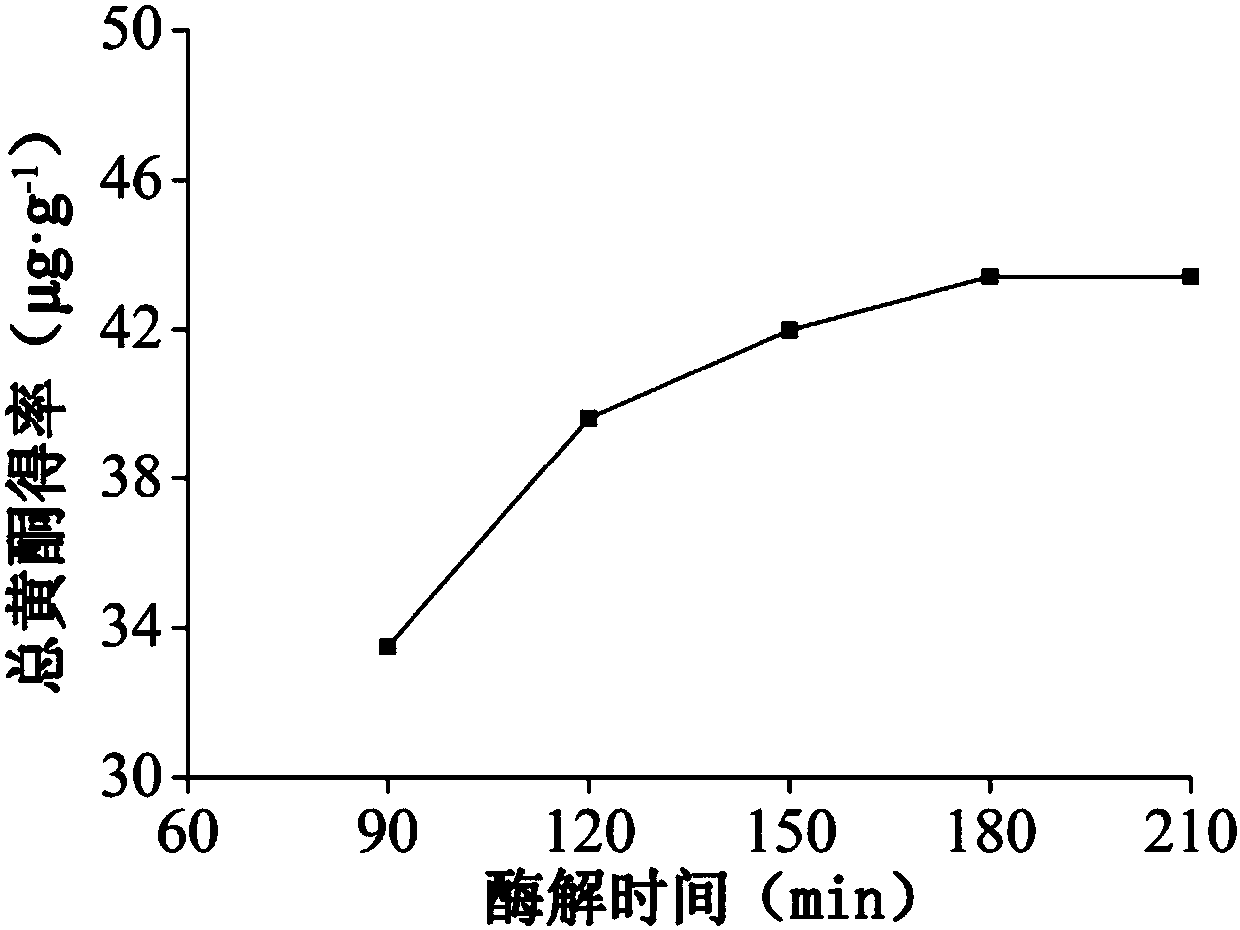

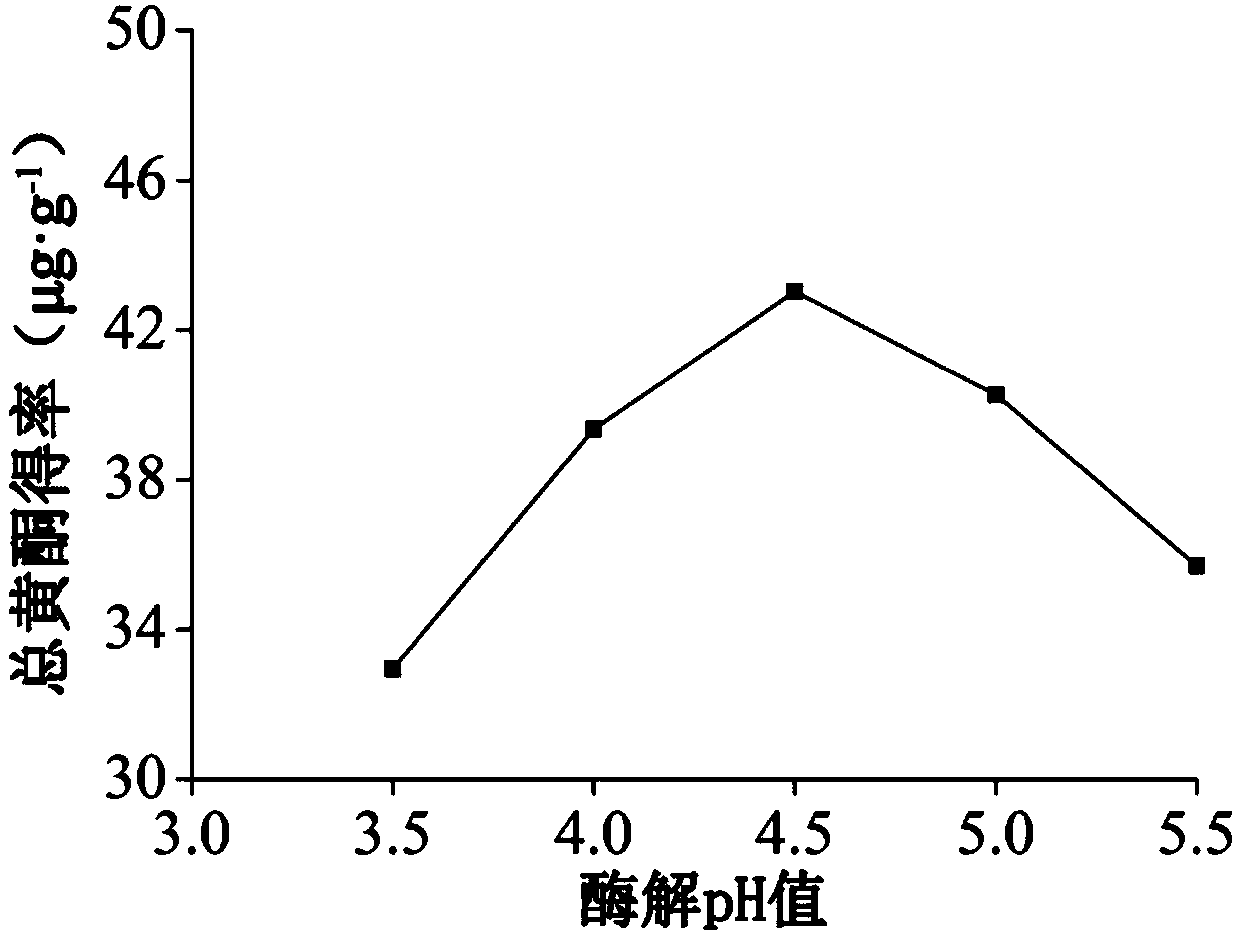

[0079] Weigh 10.00 g of viola chinensis powder, add acetic acid-sodium acetate buffer solution, adjust the pH to 4.6, add 1.8% cellulase according to the mass ratio of medicinal materials, and enzymatically hydrolyze at 50°C for 155 minutes;

[0080] Concentrate the crude extract to a thick paste with a rotary evaporator, and dry it in a vacuum oven for 24 hours to obtain the crude extract.

[0081] Weigh the above-mentioned crude matter, dissolve it with anhydrous methanol, and after dilution, use high-performance liquid chromatography to measure violadin apigenin, and according to the apigenin yield Y=[(apigenin content×extract weight) / zihuadi D medicinal material weight] × 100%. The calculated yield of apigenin was 41.26μg / g.

Embodiment 2

[0083] Drying and pulverizing Viola Viola into 90 meshes to obtain Viola Viola powder;

[0084] Weigh 10.00 g of viola powder, add acetic acid-sodium acetate buffer solution, adjust the pH to 5.5, add 2.4% cellulase according to the mass ratio of medicinal materials, and enzymolyze at 60°C for 210 minutes;

[0085] Concentrate the crude extract to a thick paste with a rotary evaporator, and dry it in a vacuum oven for 30 hours to obtain the crude extract.

[0086] Weigh the above-mentioned crude matter, dissolve it with anhydrous methanol, and after dilution, use high-performance liquid chromatography to measure violadin apigenin, and according to the apigenin yield Y=[(apigenin content×extract weight) / zihuadi D medicinal material weight] × 100%. The calculated yield of apigenin was 41.05μg / g.

Embodiment 3

[0088] Drying and pulverizing Viola Viola into 70 meshes to obtain Viola Viola powder;

[0089] Weigh 10.00 g of viola chinensis powder, add acetic acid-sodium acetate buffer solution, adjust the pH to 3.5, add 1.2% cellulase according to the mass ratio of medicinal materials, and enzymatically hydrolyze at 40°C for 90 minutes;

[0090] Concentrate the crude extract to a thick paste with a rotary evaporator, and dry it in a vacuum oven for 12 hours to obtain the crude extract.

[0091] Weigh the above-mentioned crude matter, dissolve it with anhydrous methanol, and after dilution, use high-performance liquid chromatography to measure violadin apigenin, and according to the apigenin yield Y=[(apigenin content×extract weight) / zihuadi D medicinal material weight] × 100%. The calculated yield of apigenin was 40.24μg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield | aaaaa | aaaaa |

| Yield | aaaaa | aaaaa |

| Yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com