Upper and lower combined low-NOx single regenerative burner

A combined, single heat storage technology, applied in the field of heating gas combustion in heating furnaces and heat treatment furnaces, to achieve the effects of reducing combustion speed, lengthening flame length and improving heating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

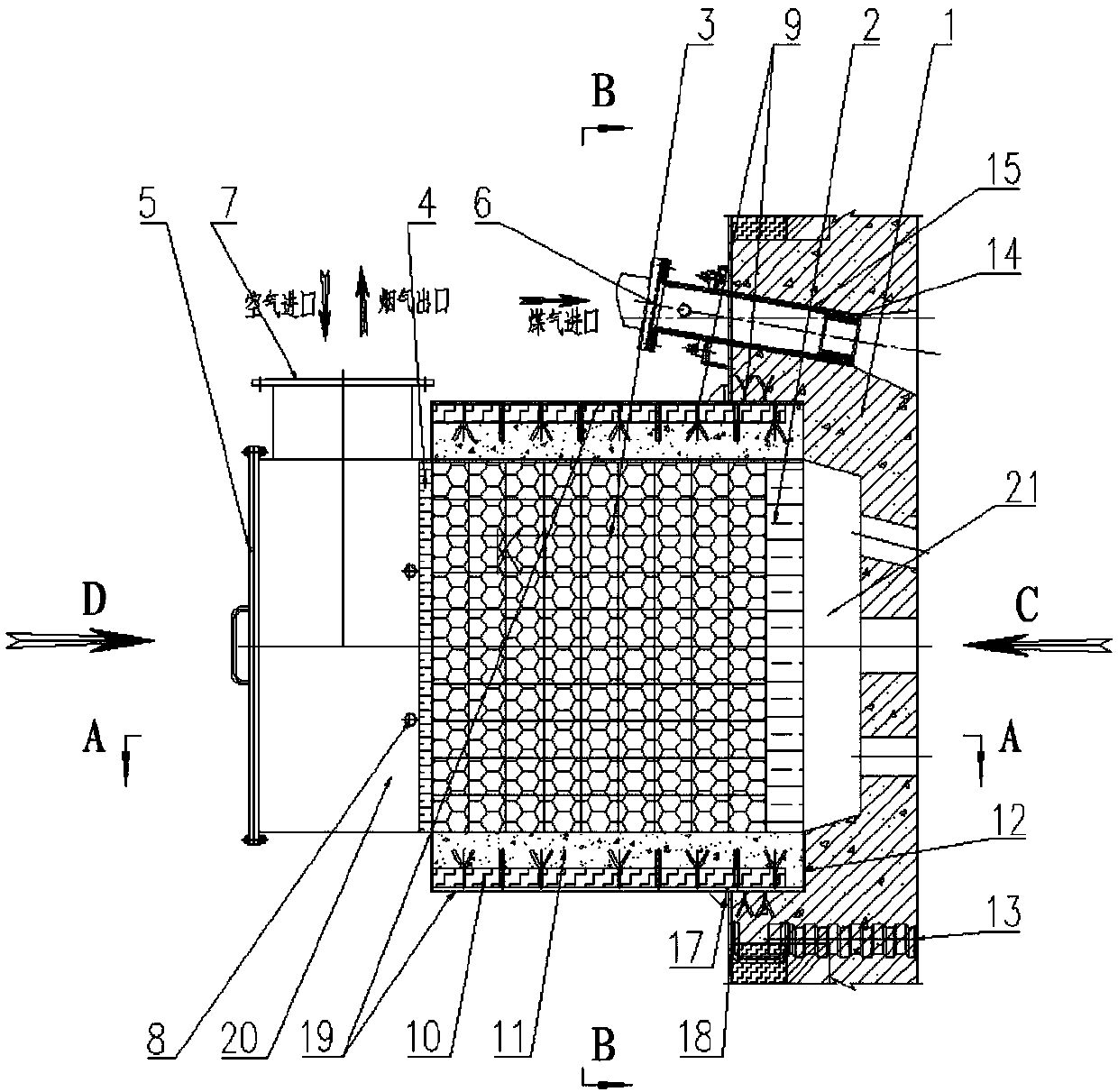

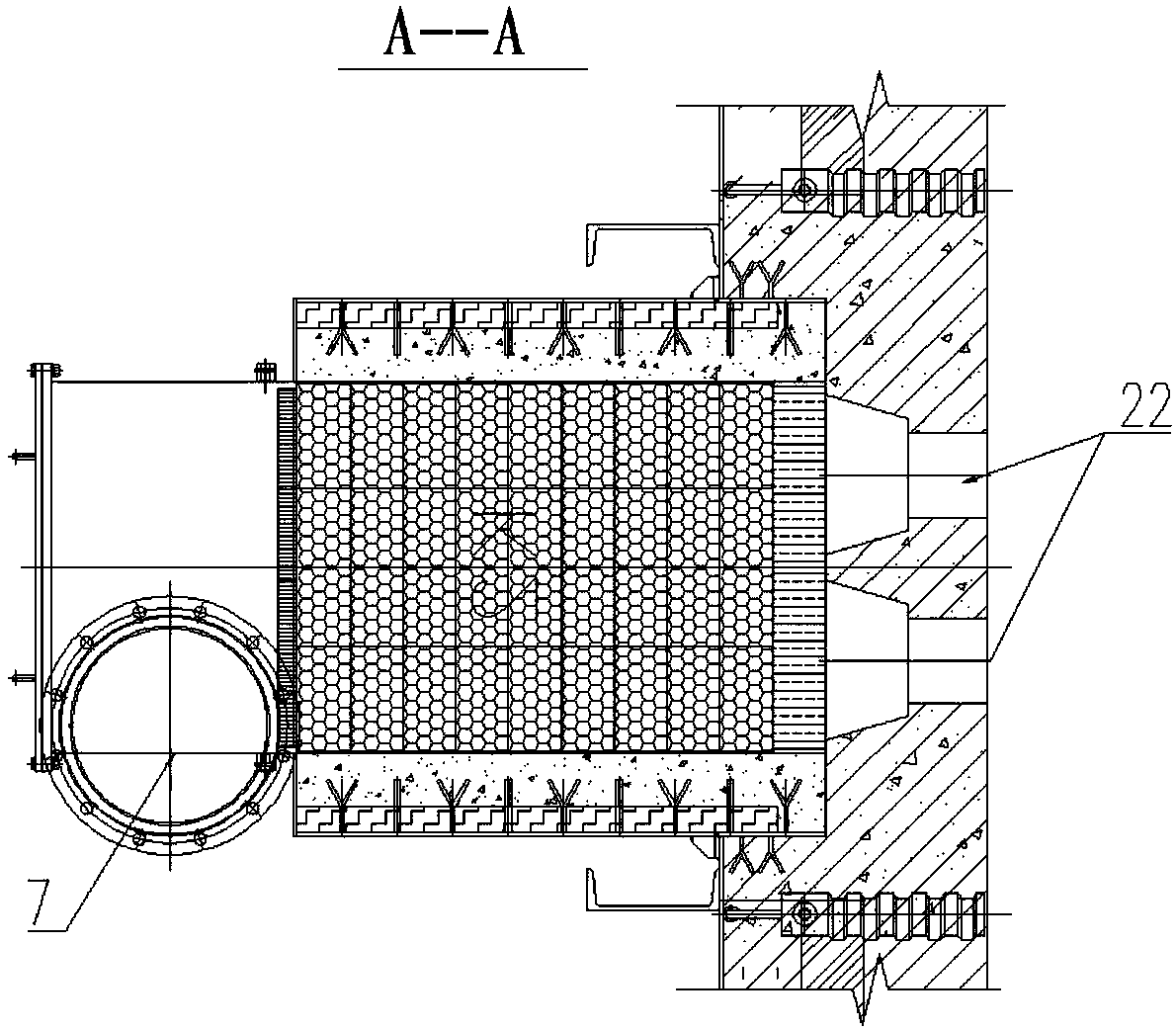

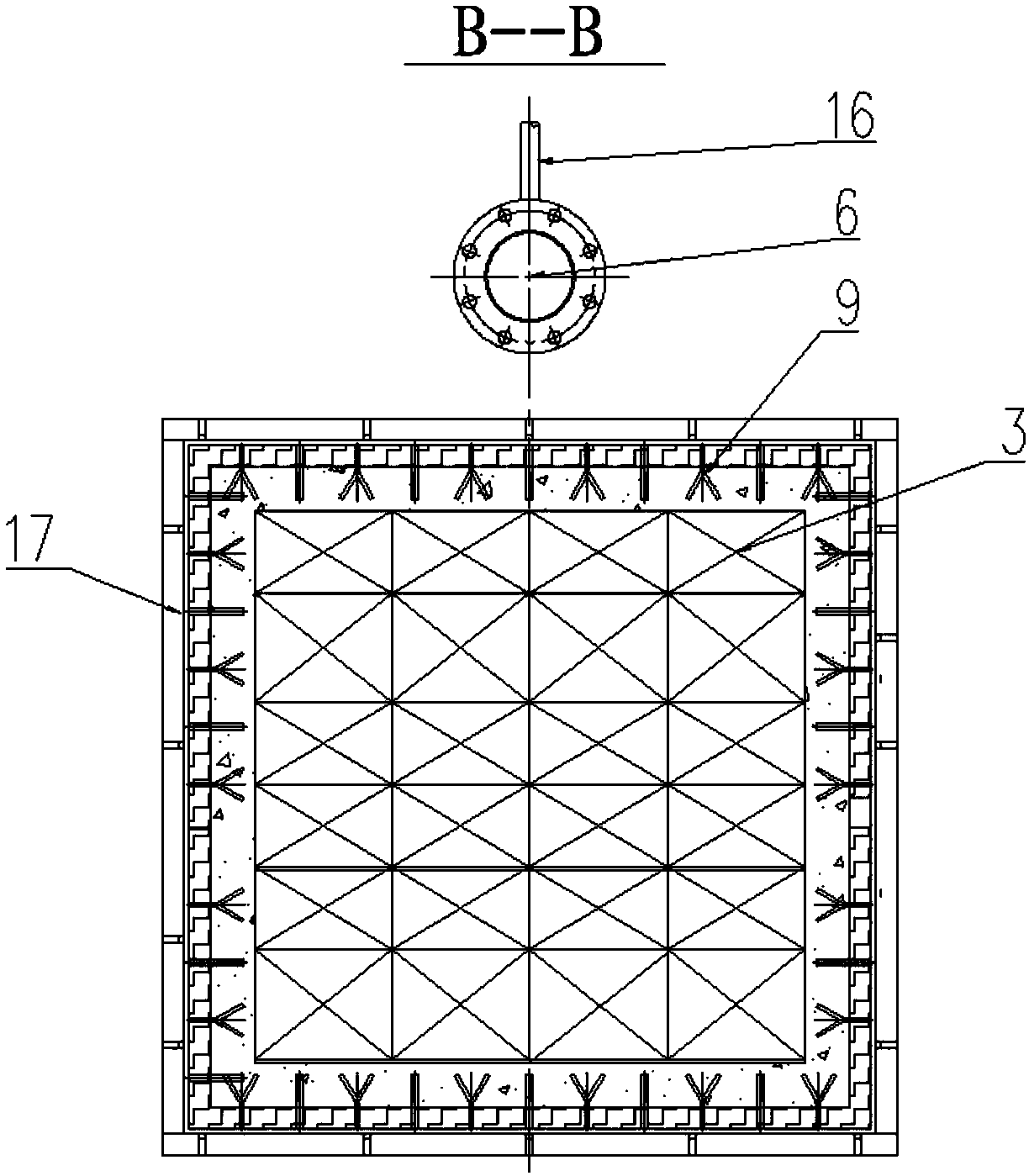

[0021] figure 1 — Figure 5 It is a specific embodiment of the present invention.

[0022] The present invention includes a porous burner brick 1, an air heat storage box, a heat storage body 3, and a gas nozzle 14; the porous burner brick 1 and the furnace wall are integrally casted with refractory castables of the same material, and installed at the front end of the air heat storage box; The regenerator 3 is installed in the air heat storage box; the gas nozzle is installed in the air heat storage box; the front end of the air heat storage box extends into the furnace wall by 150mm, and is continuously welded with the furnace wall steel plate.

[0023] The porous burner brick 1 is installed at the front end of the air heat storage box, and is made of the same material as the furnace wall AL 2 o 3 ≥65% low cement castable integral casting molding process. The surrounding of the porous burner brick 1 is fixed on the furnace wall steel plate 18 by the anchor brick 13, the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com