Intelligent cover matching system for heating cover of cover furnace and cover matching method

A technology of heating mantle and bell-type furnace, which is applied in energy-saving calculation, instrument, electric digital data processing and other directions, can solve the problems of unreasonable utilization of heating mantle, waste of gas resources, low utilization rate of equipment, etc. The effect of reducing heat loss and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

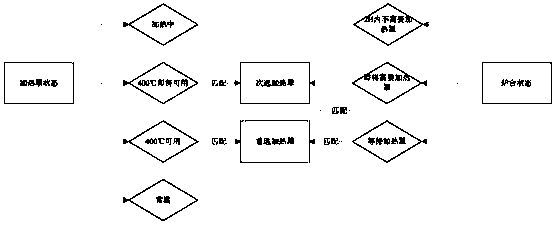

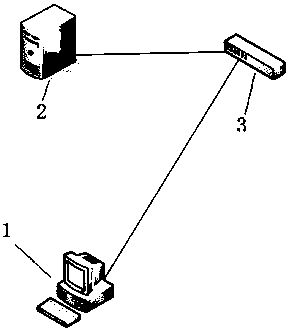

[0023] Such as Figure 1-Figure 4 As shown, an intelligent cover matching system for a bell furnace heating cover according to the present invention includes a bell furnace cover matching tool terminal 1, which is characterized in that the bell furnace cover matching tool terminal 1 communicates with the cover through a switch 3 The furnace screen and the database server 2 realize data exchange, read the heating mantle status and serial number parameters, and furnace base status and serial number parameters. After intelligent optimal matching, the feedback displays the matched heating mantle number m and the matching furnace base number n, which is convenient On-site operators withhold licenses.

[0024] The terminal 1 of the bell-type furnace matching tool is composed of a computer terminal and a display, wherein the computer terminal is prefera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com