Degradable soluble ceramic fiber plaster and usage method thereof

A ceramic fiber and soluble technology, applied in the field of cement, can solve the problems of easy dust generation, easy falling off, sudden drop in strength, etc., achieve good compatibility and adaptability, solve the effect of low strength and improve the status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

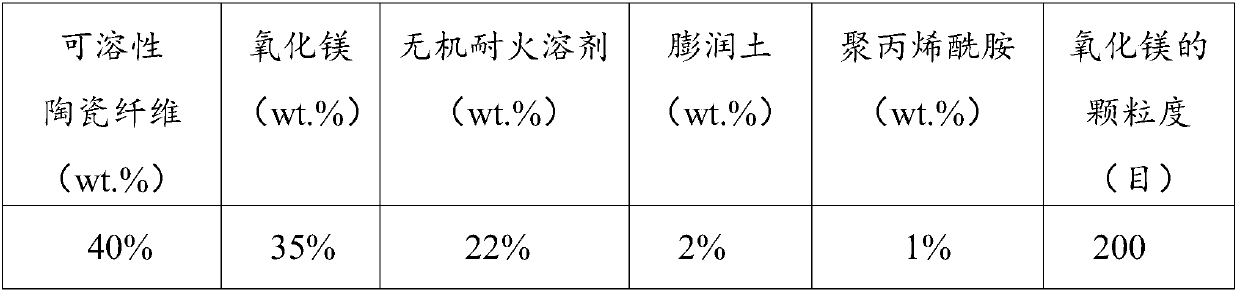

[0024] Carry out raw material according to the proportioning of table 1:

[0025] Table 1. Raw material ratio 1

[0026]

[0027] First, silica sol with a concentration of 30% is provided and mixed with water at a volume ratio of 2:1 to obtain an inorganic refractory solvent with a mass fraction of 22%. Secondly, the mass percentage is divided into 40% soluble ceramic fiber, 35% magnesia, 2% bentonite, 1% polyacrylamide and 22% inorganic refractory solvent obtained above for mixing, wherein the particles of magnesia The degree is 200 mesh. Then, the mixed raw materials are stirred for 2 hours to finally form a fiber mud-like cement product.

[0028] Take an appropriate amount of the obtained fibrous mud product, add 1.5% water and stir evenly. Among them, the amount of water added is within the range of 0% to 3%, which has no effect on the flexural strength itself, but only affects the workability. Adding water and stirring during use can improve the workability. Only w...

Embodiment 2

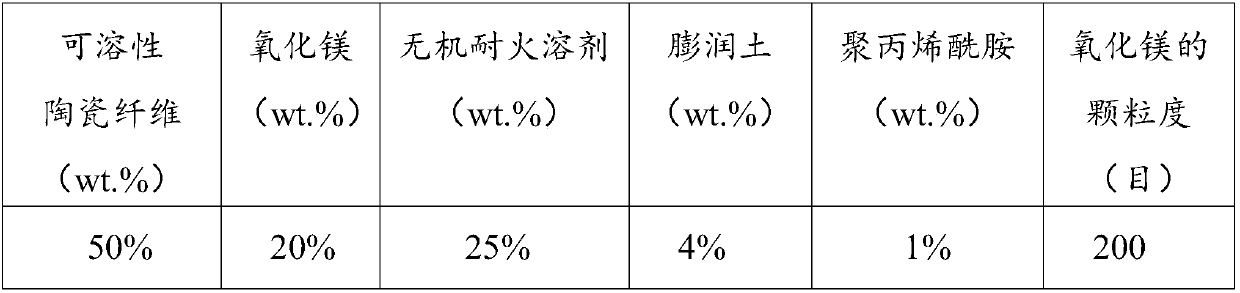

[0031] Carry out raw material according to the proportioning of Table 2:

[0032] Table 2. Raw material ratio 2

[0033]

[0034] First, silica sol with a concentration of 30% is provided and mixed with water at a volume ratio of 3:1 to obtain an inorganic refractory solvent with a mass fraction of 25%. Secondly, take 50% soluble ceramic fiber, 20% magnesia, 4% bentonite, 1% polyacrylamide and 25% inorganic refractory solvent obtained above to mix, wherein the particle size of magnesia It is 200 mesh. Then, the mixed raw materials are stirred for 2 hours to finally form a fiber mud-like cement product.

[0035] Take an appropriate amount of the obtained fibrous mud product, add 1% water and stir evenly. Among them, the amount of water added is in the range of 0% to 3%, which has no effect on the flexural strength of itself, but only affects the workability. During use, it is necessary to add water for stirring to improve the workability. Only when the amount of water ad...

Embodiment 3

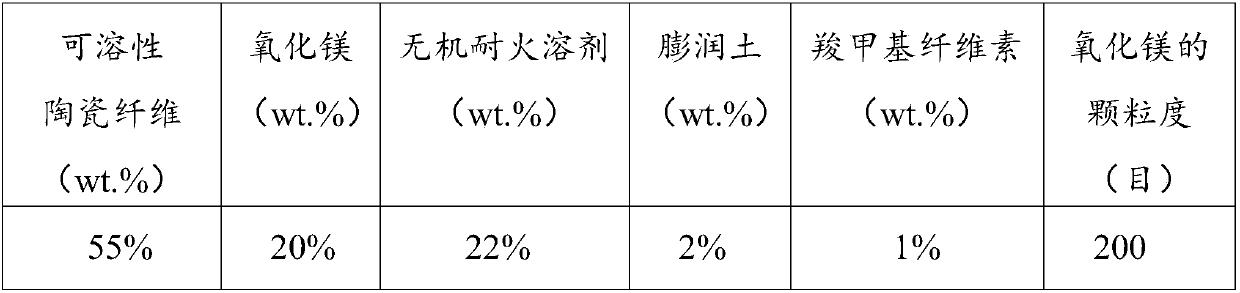

[0038] Carry out raw material according to the proportioning of table 3:

[0039] Table 3. Raw material ratio 3

[0040]

[0041] First, silica sol with a concentration of 30% is provided and mixed with water at a volume ratio of 2:1 to obtain an inorganic refractory solvent with a mass fraction of 22%. Secondly, get the soluble ceramic fiber that is 55% by mass percentage, 20% magnesium oxide, 2% bentonite, 1% carboxymethyl cellulose and the inorganic refractory solvent of 22% that get before and mix, wherein the magnesium oxide The particle size is 200 mesh. Then, the mixed raw materials are stirred for 2 hours to finally form a fiber mud-like cement product.

[0042]Take an appropriate amount of the obtained fibrous mud product, add 1.5% water and stir evenly. Among them, the amount of water added is in the range of 0% to 3%, which has no effect on the flexural strength of itself, but only affects the workability. During use, it is necessary to add water for stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com