Multifunctional winding film-coating machine based on electronic industry

A multi-functional technology in the electronics industry, applied in the field of coating machines, can solve the problems of time-consuming and laborious spraying of lubricating oil, affecting the cooling process, poor heat insulation effect of equipment, etc., to speed up the cooling process, speed up, good sealing and heat insulation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

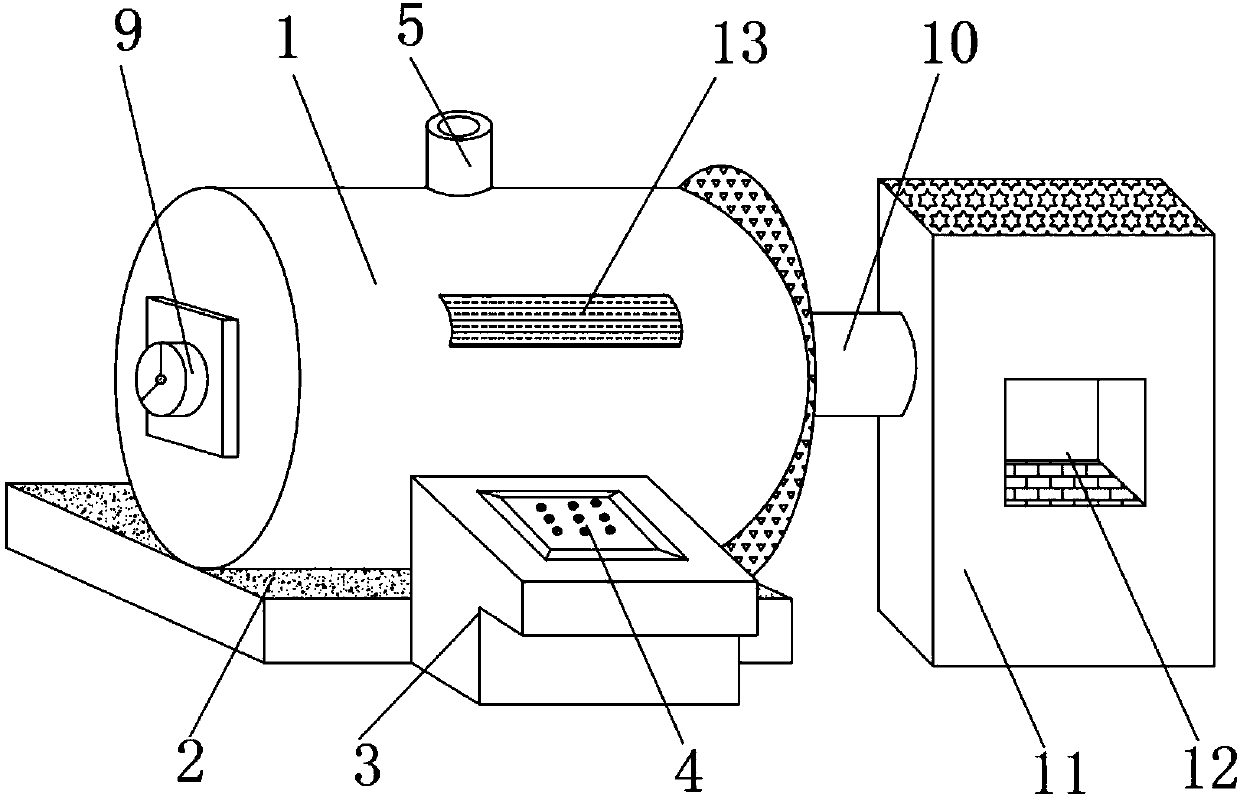

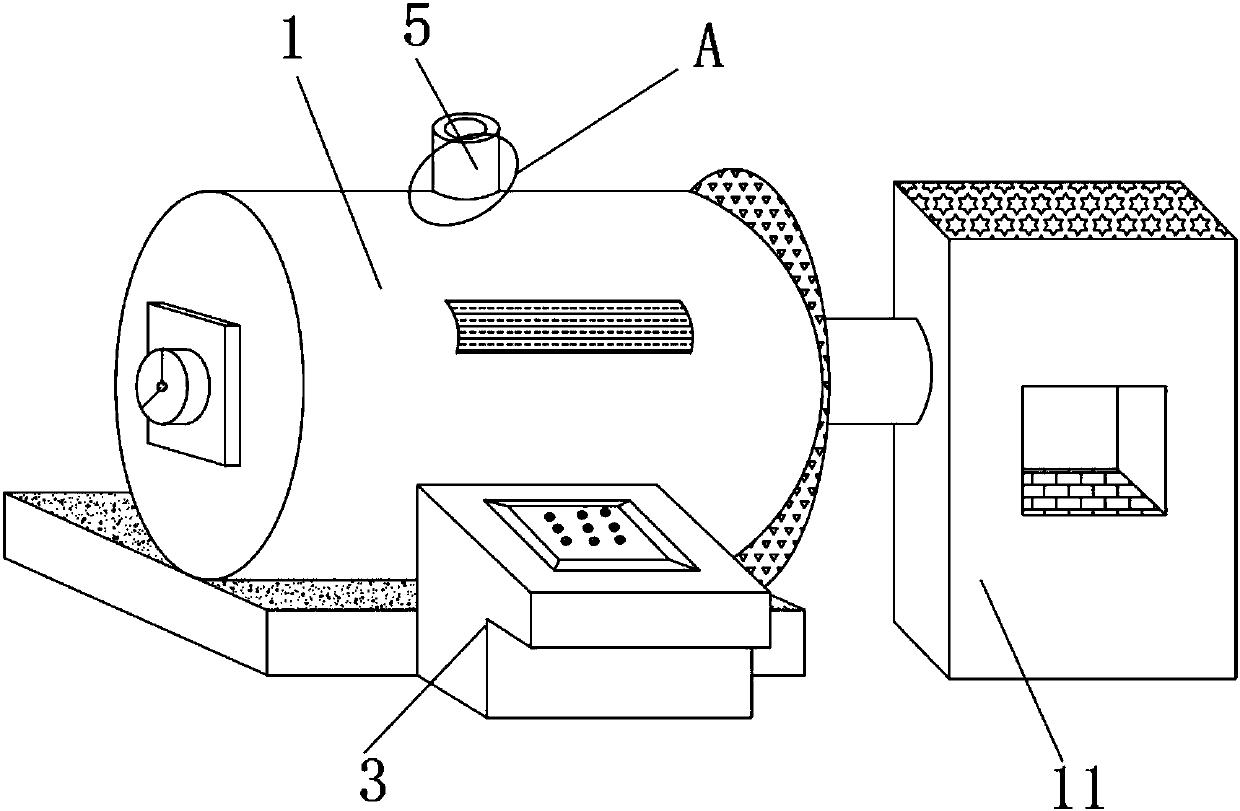

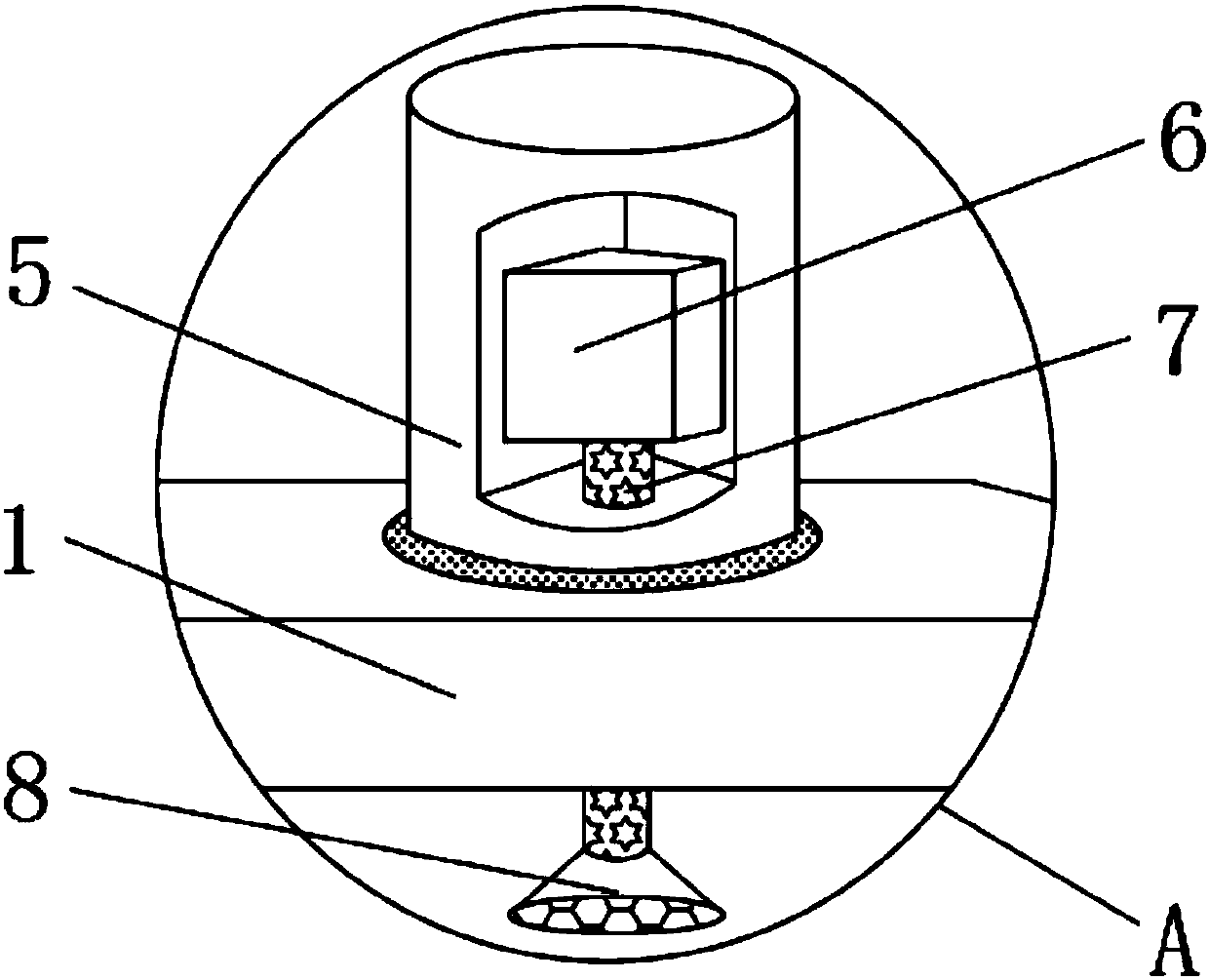

[0022] Such as Figure 1-4 Shown, a kind of multi-functional roll-to-roll coating machine based on electronic industry, comprises coating machine case 1 and insulation plate 18, and the outside of the lower end of coating machine case 1 is fixedly installed with base 2, and the position outside one end of base 2 near coating machine case 1 is set There is an operation table 3, the upper surface of the operation table 3 is provided with a control panel 4, and the upper outer surface of the coating cabinet 1 is equipped with a C2 automatic lubricator 5, which improves the maintenance quality of the equipment and saves time and effort, and the C2 automatic lubricator 5 An oil storage tank 6 is fixedly installed in the interior of the oil storage tank...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap