PU leather with color changing function through refraction of light and preparation method of PU leather

A technology of light refraction and discoloration layer, which is applied in chemical instruments and methods, printing and printing process for producing special varieties of printed matter, etc. High bonding strength, unique appearance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

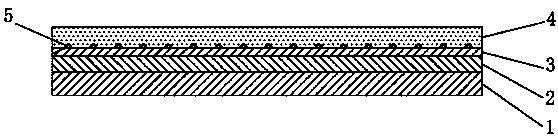

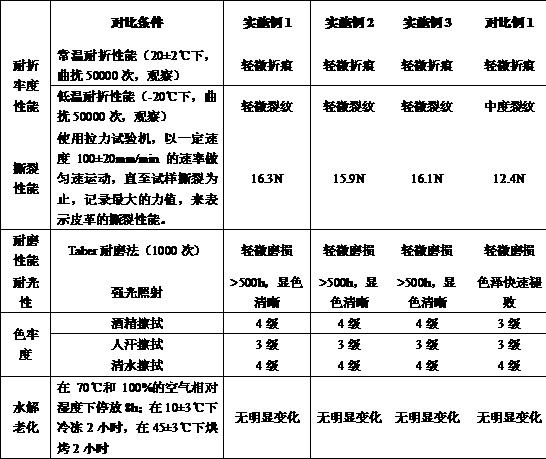

[0033] A PU leather with photorefractive discoloration, comprising a base cloth layer 1, a foam layer 2 is compounded on the base cloth layer 1, a color-changing layer 3 is compoundly disposed on the foam layer 2, and a color-changing layer 3 is disposed on the color-changing layer 3 Compositely provided with a PU surface layer 4; wherein the discoloration layer 3 is a metal film with a plurality of protrusions 5, and the metal film is made of gold material; the protrusions 5 are provided with multiple surfaces, which are pyramid-shaped and evenly distributed On the surface of the film; through a three-dimensional printing machine, 3D color-changing pearlescent pigments are used to color the protrusions 5 on the film surface; the same color is printed on the sides of the protrusions 5 facing the same direction, and all the protrusions 5 are printed on the sides facing different directions different color.

[0034] The preparation steps of the photorefractive color-changing PU ...

Embodiment 2

[0041] A PU leather with photorefractive discoloration, comprising a base cloth layer 1, a foam layer 2 is compounded on the base cloth layer 1, a color-changing layer 3 is compoundly disposed on the foam layer 2, and a color-changing layer 3 is disposed on the color-changing layer 3 Compositely provided with a PU surface layer 4; wherein the discoloration layer 3 is a metal film with a plurality of protrusions 5, and the metal film is made of aluminum material; Distributed on the surface of the film; through a three-dimensional printing machine, and use 3D color-changing pearlescent pigments to color the protrusions 5 on the film surface; the same color is printed on the faces of the protrusions 5 facing the same direction, and all the faces of the protrusions 5 facing different directions Printed in different colors.

[0042] The preparation steps of the photorefractive color-changing PU leather are as follows:

[0043] A. Weigh the PU surface layer raw materials, specific...

Embodiment 3

[0049] A PU leather with photorefractive discoloration, comprising a base cloth layer 1, a foam layer 2 is compounded on the base cloth layer 1, a color-changing layer 3 is compoundly disposed on the foam layer 2, and a color-changing layer 3 is disposed on the color-changing layer 3 Compositely provided with a PU surface layer 4; wherein the discoloration layer 3 is a metal film with a plurality of protrusions 5, and the metal film is made of silver material; Distributed on the surface of the film; through a three-dimensional printing machine, and use 3D color-changing pearlescent pigments to color the protrusions 5 on the film surface; the same color is printed on the faces of the protrusions 5 facing the same direction, and all the faces of the protrusions 5 facing different directions Printed in different colors.

[0050] The preparation steps of the photorefractive color-changing PU leather are as follows:

[0051] A. Weigh the PU surface layer raw materials, specifical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com