Device and method for measuring material level and concentration in thickener

A concentration measurement and thickener technology, which is applied in measurement devices, specific gravity measurement, engine lubrication, etc., can solve the problems of high equipment requirements and high measurement costs, and achieve high measurement accuracy, prolong life, and reduce errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

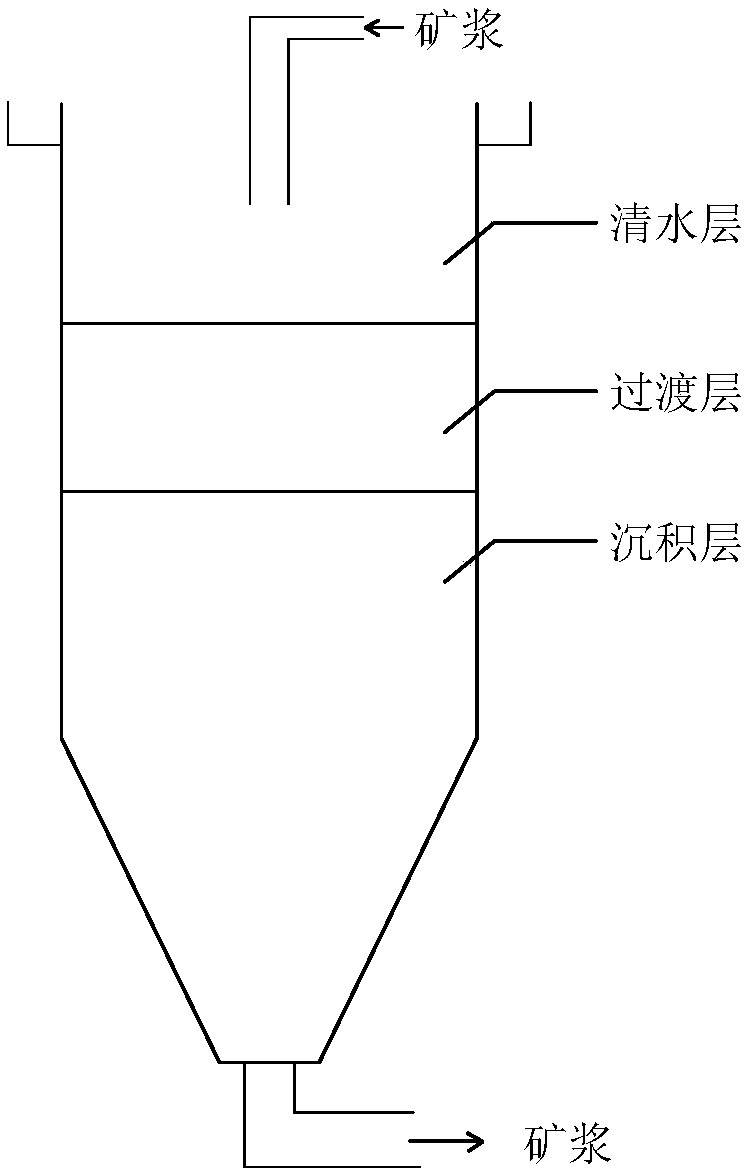

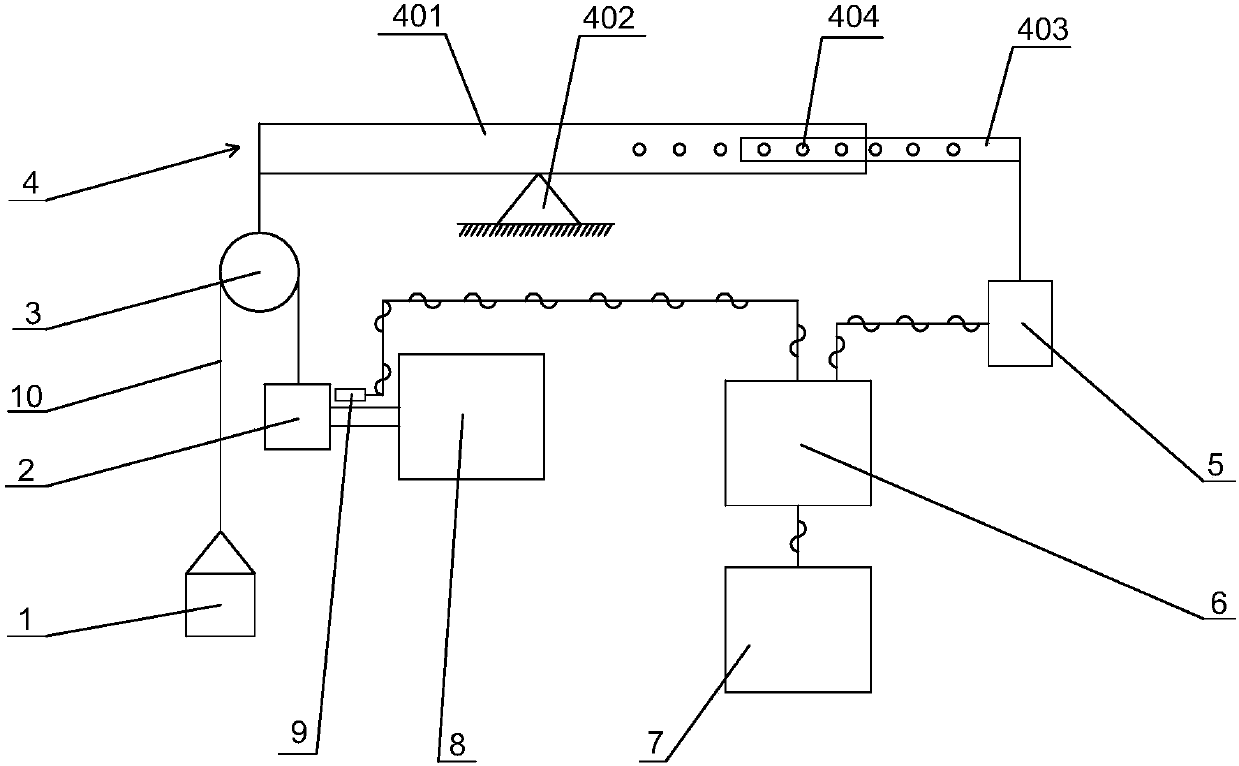

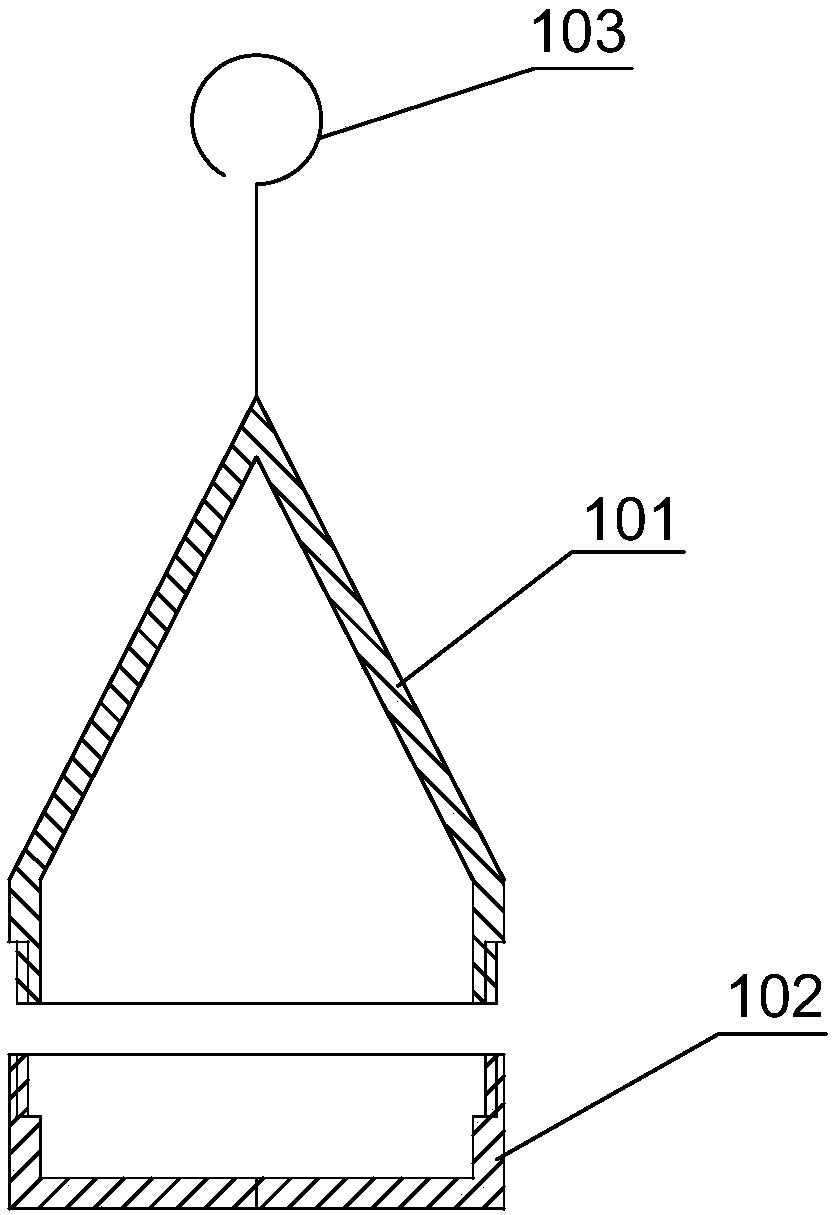

[0029] In conjunction with the accompanying drawings, a device for measuring material level and concentration in a thickener includes an actuator, a detection mechanism, and a processing and display mechanism. The actuator includes a weight 1, a winding wheel 2, a pulley 3 and a servo motor 8. The detection mechanism includes a lever 4, a pressure sensor 5 and an encoder 9, and the processing and display mechanism includes a PLC controller 6 and a display 7. The weight 1 is connected to one end of the rope 10, and the other end of the rope 10 is wound around the pulley 3 and then wound on the reel 2, and the reel 2 is connected with the servo motor 8, and the servo motor 8 is driven to run. The pulley 3 is connected to one end of the lever 4, the pressure sensor 5 is connected to the other end of the lever 4, and the encoder 9 is arranged at the reel 2 for recording the number of turns of the reel 2. The pressure sensor Both 5 and the encoder 9 are connected with the PLC contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com