Spatial camera with surrounding support type electronics assembly

A technology of space camera and electronics, which is applied in the field of space optics, can solve problems affecting camera assembly and adjustment, and achieve the effects of improving mechanical properties, high rigidity of the overall structure, and reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

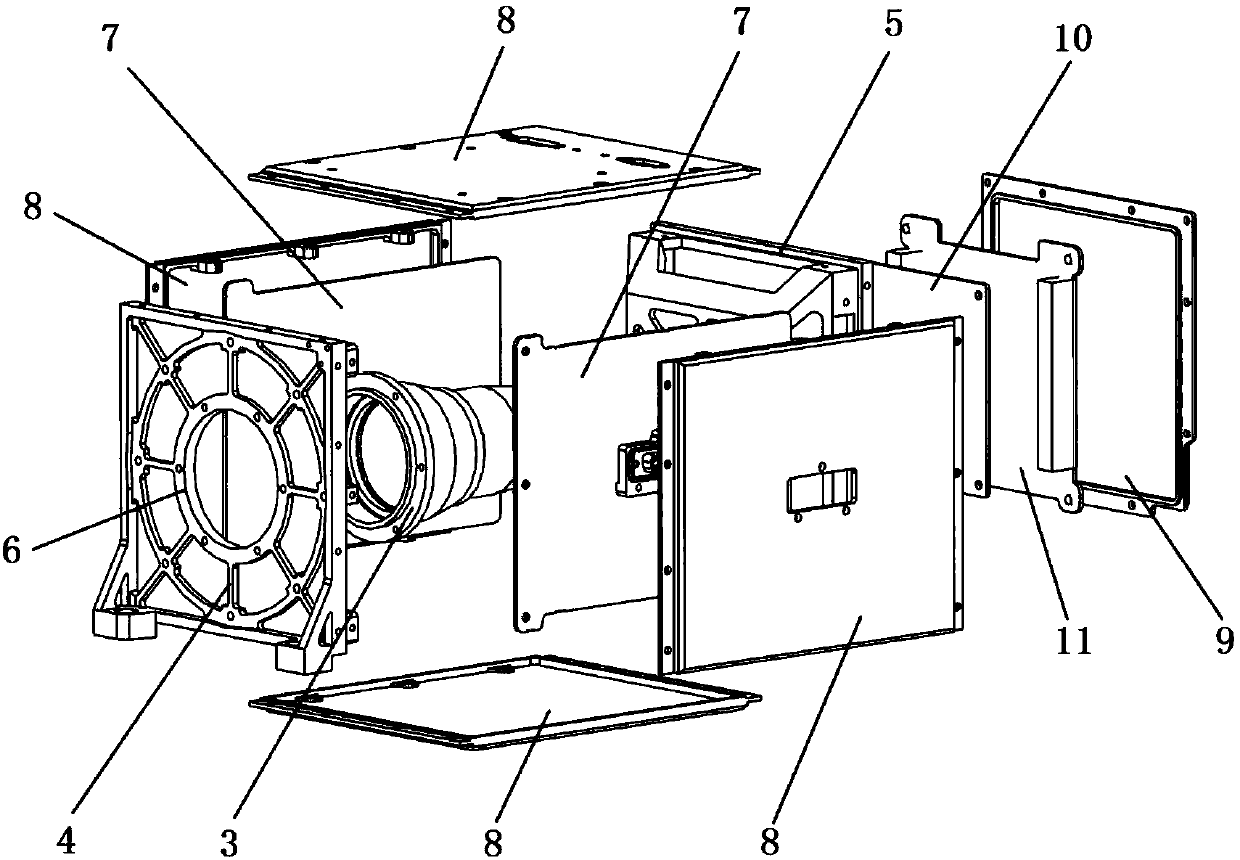

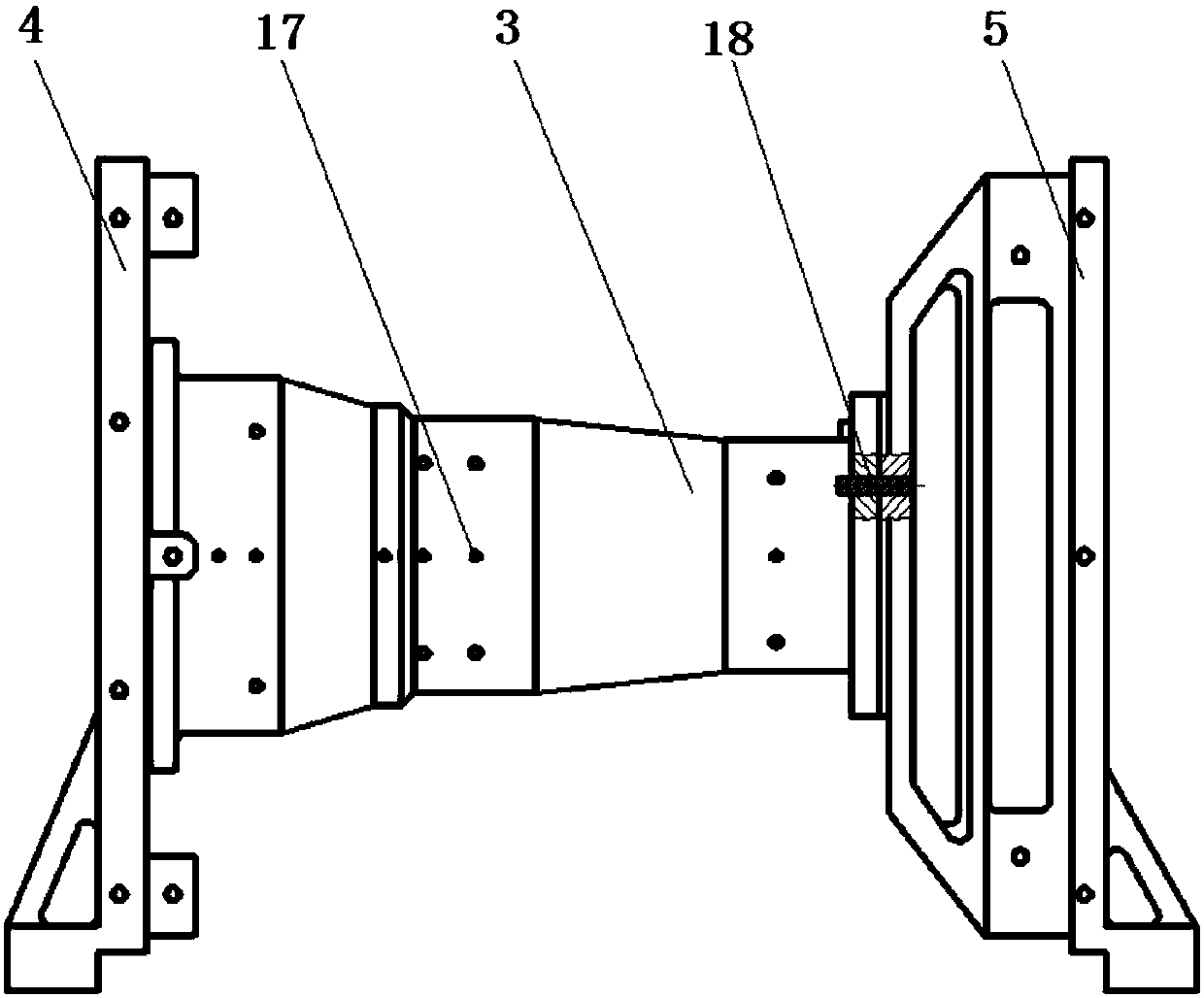

[0043] see figure 2 , the present invention provides a kind of space camera with surrounding support type electronic assembly, the structure of its preferred embodiment comprises optical lens barrel 3, and the front of optical lens barrel 3 is provided with front support 4, and the back side of optical lens barrel 3 is provided with The rear bracket 5 , the front bracket 4 and the rear bracket 5 are all perpendicular to the optical axis of the optical lens barrel 3 ; the front bracket 4 is provided with a circular light hole 6 corresponding to the position of the optical lens barrel 3 . like image 3 As shown, the optical lens barrel 3 is matched with the front bracket 4 and the rear bracket 5 through seams, and is connected into one body by screws. The front bracket 4 and the optical lens barrel 3, the rear bracket 5 and the optical lens barrel 3 are all positioned by cylindrical pins 18; the optical lens barrel 3 is provided with threaded glue injection holes 17.

[0044]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com