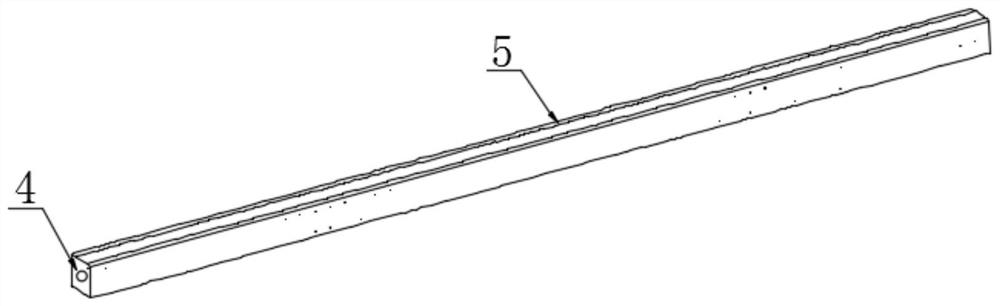

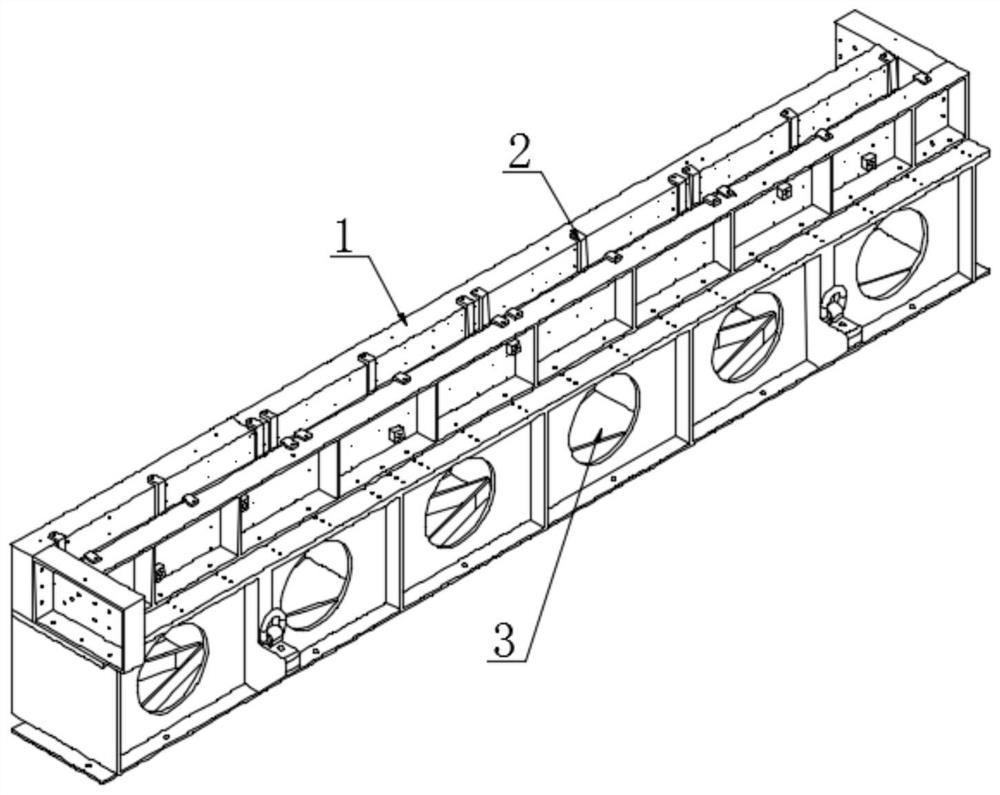

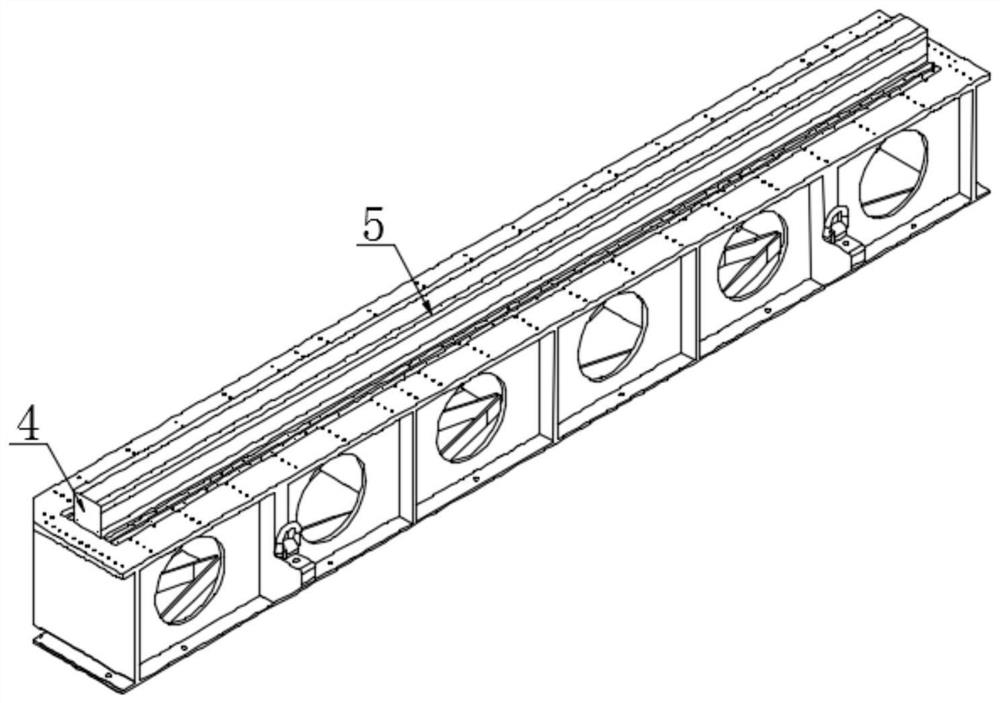

Truss cross beam and manufacturing method thereof

A technology of trusses and beams, which is applied in the field of trusses and beams and its production, which can solve the problems of unstable precision, high noise, and large vibration of truss beams, and achieve the effects of good precision retention, improved rigidity of the overall structure, and low deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In Example 1, in terms of mass percentage, the marble floor rail is naturally cured by 15% of 16mm pebbles, 28% of 8mm basalt grains, 40% of 3mm quartz sand, 16% of liquid epoxy resin, and 1% of curing agent.

Embodiment 2

[0050] In Example 2, in terms of mass percentage, the marble floor rail is naturally cured by 25% of 16mm pebbles, 20% of 8mm basalt grains, 35% of 3mm quartz sand, 19% of liquid epoxy resin, and 1% of curing agent.

Embodiment 3

[0051] In embodiment 3, by mass percentage, the marble floor rail is made of 15% of 16mm cobblestone, 28% of 8mm basalt grain, 35% of 3mm quartz sand, 16% of liquid epoxy resin, 1% of curing agent and 6% of the length is 8mm The glass fiber staple fiber is naturally cured.

[0052] The comparative example is a square pipe ground rail made by the existing welding process mentioned in the background art.

[0053] Measure the modulus of elasticity, tensile strength, compressive strength, thermal conductivity and vibration coefficient of each embodiment and comparative examples, and the results are as shown in table 1:

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com