Nut tightener control system

A control system and tightening machine technology, applied in the field of machinery, can solve the problems of difficulty in ensuring accuracy, high cost performance, low production efficiency, etc., and achieve the effects of improving production efficiency and assembly accuracy, long trouble-free working time, and good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

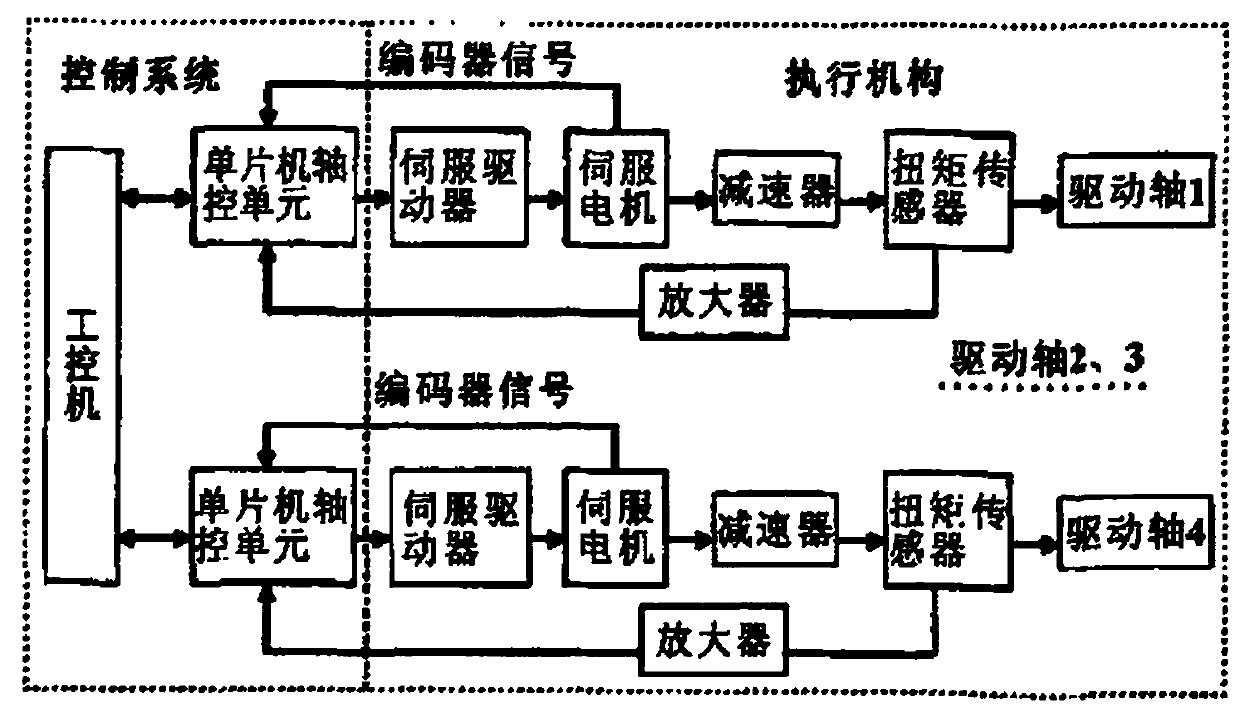

[0014] like figure 1 , The tightening machine is composed of two parts: the control system and the driving actuator. The control system is composed of an industrial computer and 4 single-chip axis control units; The axis control unit uses a single-chip microcomputer as the core controller.

[0015] The actuator is composed of AC servo motor, angle sensor, torque sensor, reducer and power output shaft. Each axis control unit independently controls a set of actuators. 4 sets of actuators are installed in the headstock, and the automatic tightening process is completed by operating the headstock.

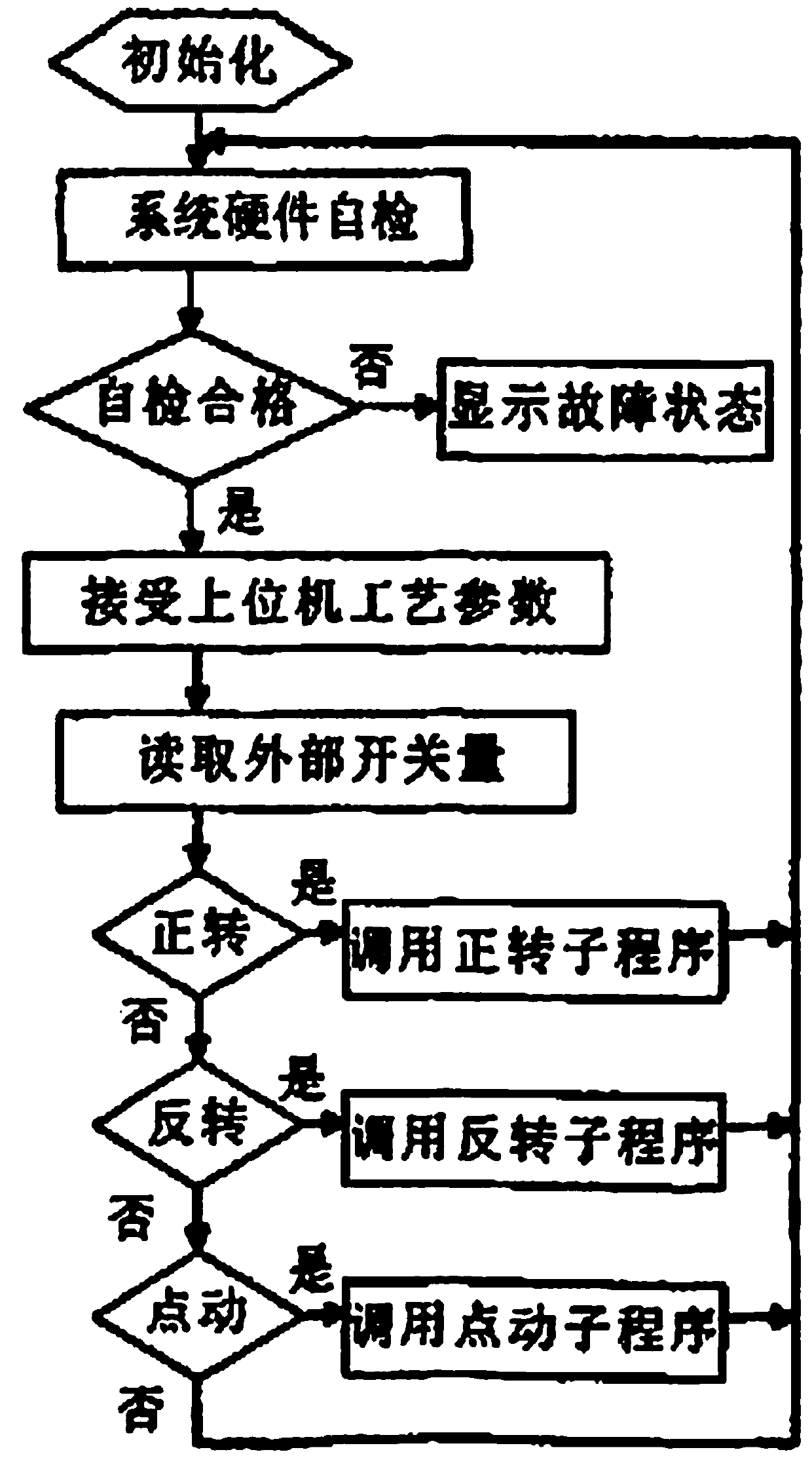

[0016] like figure 2 , The monitoring unit adopts industrial computer as the hardware platform, through the monitoring software of the industrial computer to realize the setting of the predetermined torque value, the dynamic data of the tightening process, the real-time dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com