Single power supply integrated h-bridge DC motor drive module with complementary dead zone and isolation

A DC motor and drive module technology, applied in the field of excitation or armature current control, etc., can solve the problems that it is difficult to meet the miniaturization requirements of aerospace servo products, the built-in dead zone protection function is not available, and the hardware circuit is complex, so as to reduce signal delay. Effects of time, shortened interconnect length, and reduced size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]The present invention will be further described in detail below with reference to the accompanying drawings and examples.

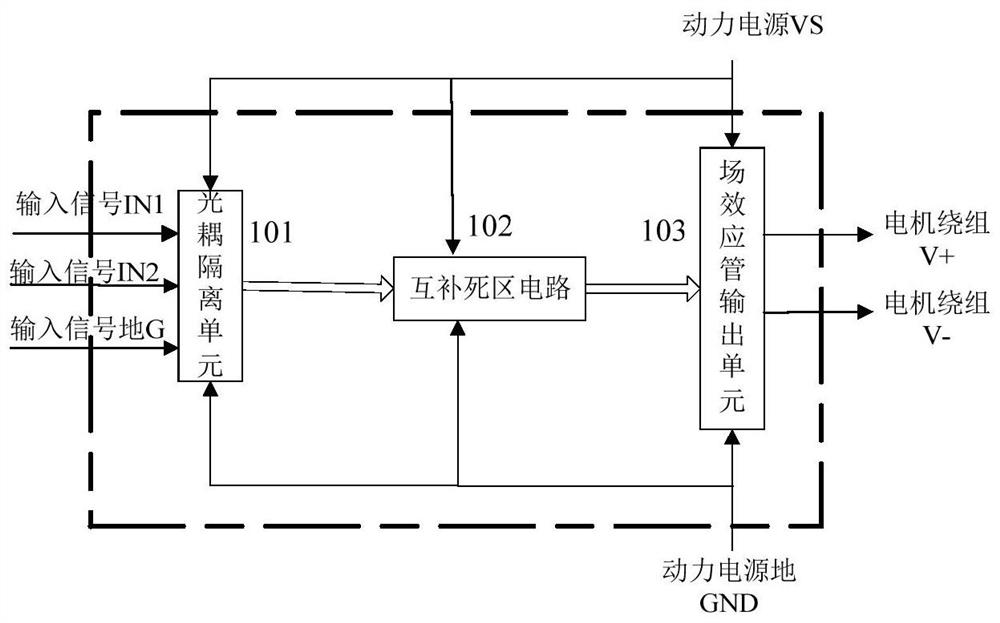

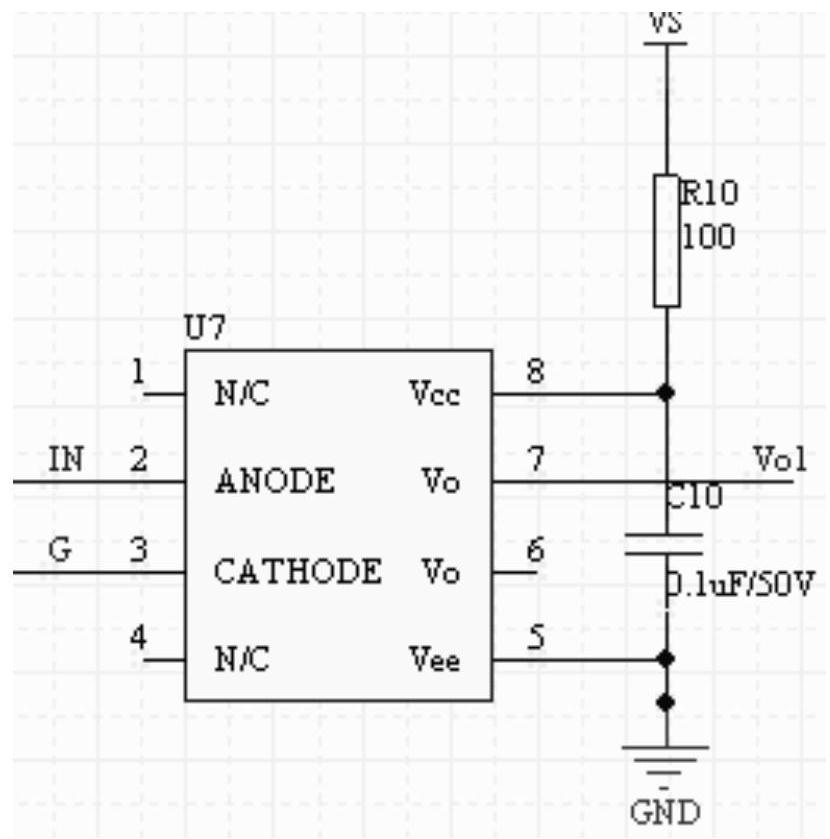

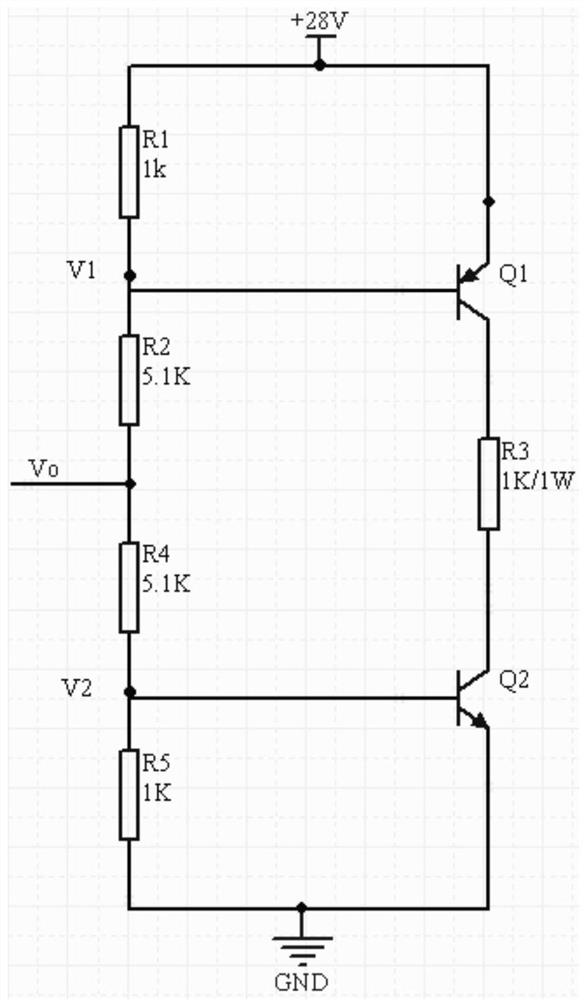

[0021]Such asfigure 1 As shown, a single power supply integrated h-bridge DC motor drive module with a hardware complementary dead zone zone, which includes a photocouplex isolation unit 101, a mutual deadline circuit 102, and a field effect tube output unit 103. The external pin of the optical coupling unit 101 connects the module, receives the TTL control signal or directly by the motor control using the DSP control signal, and the output terminal of the photocouplex isolation unit 101 is connected to the input of the complementary deadline circuit 102, and complement each other The region circuit 102 output is connected to the input of the field effect tube output unit 103, and the output terminal of the field effect tube output unit 103 connects the outer pin V +, V-, pin V +, V- of the module to connect the two phases of the DC motor, respectively. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com