Material falling device

A blanking device and hot forming technology, applied in forging/pressing/hammer devices, metal rolling, manufacturing tools, etc., can solve the problems of insufficient machining allowance, distortion of the receiving plate, insufficient surface hardness, etc. It is not easy to be deformed or failed by heat, high heat resistance and deformation resistance, and excellent spring steel performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

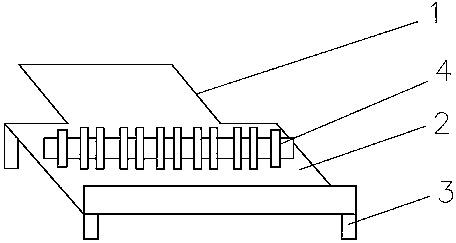

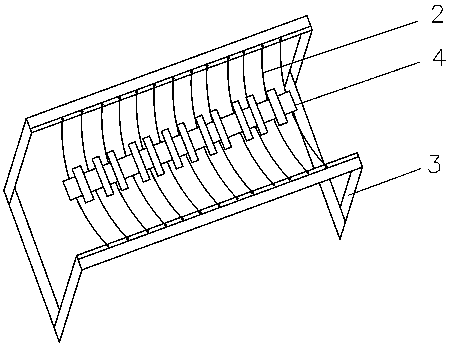

[0027] see figure 2 , figure 2 It is a blanking device of the present invention. The difference between this blanking device and Reference Document 1 is that the material receiving part 2 is no longer a material receiving plate, but metal wires arranged at intervals. This arrangement at least plays the following roles: Firstly, the contact area between the camshaft 4 and the metal wire is small, and the metal wire is smooth throughout, which avoids collision and collision with the camshaft. Risk of flying out of the splice 2.

Embodiment 2

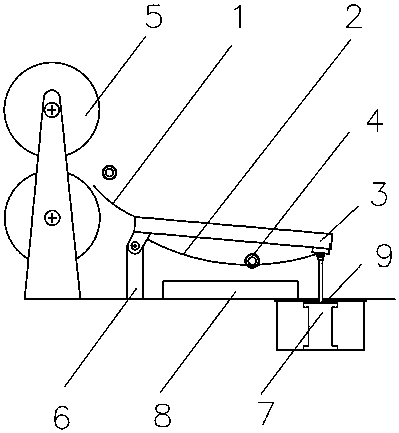

[0029] see image 3 , image 3 It is a more specific application of a blanking device of the present invention on a cross wedge rolling production line,

[0030] The cross wedge rolling production line includes a cross wedge rolling mill 5. The blanking device is integrally arranged at the blanking front end of the cross wedge rolling mill 5. The slide plate part 1 of the blanking device extends into the forming part of the camshaft 4 between the two rollers of the cross wedge rolling mill 5. The slide part 1 of the blanking device is connected to one end of the bracket 3 close to the cross wedge rolling mill 5, and the connection method is welding. In order to make the camshaft 4 and the slide part 1 form a sufficient buffer, the slide plate of the slide part 1 is designed as an arc Structure, the bottom of the end close to the cross wedge rolling mill 5 of the support 3 is hinged together with the ground support 6 arranged on the ground through the hinge frame, and the bott...

Embodiment 3

[0036] A blanking device of the present invention, such as the mechanical connection structure and transmission device described in Embodiment 1 and Embodiment 2, is easy to understand, and it achieves higher production efficiency through simple actions, and is an essential part of the present invention In the link, the material selection, manufacture and installation of the metal wire are very critical technologies.

[0037] Through continuous trial and error, the Ni-based alloy with the weight percent content of Fe finally selected between 10%-16% is used as the wire material of the present application. Ni-based alloy is a relatively good high-strength heat-resistant alloy with a reasonable formula The Ni-based alloy wire can be made to exhibit high heat resistance and deformation resistance. Preferably, the Ni-based alloy with a Fe content between 10% and 16% by weight also includes the following components (percentage by weight): 15- 20% Cr, 0.5-2% Al, 2.5-3% Mo, 0-1.2% W,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com