Vibratory powder laying device of selective laser melting formation device

A technology of laser selective melting and forming equipment, applied in the field of 3D printing, can solve the problems of unsatisfactory powder compaction effect, reduce powder bed pressure, powder cannot flow out, etc., to reduce the phenomenon of powder inclusion, improve powder fluidity, The effect of reducing performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

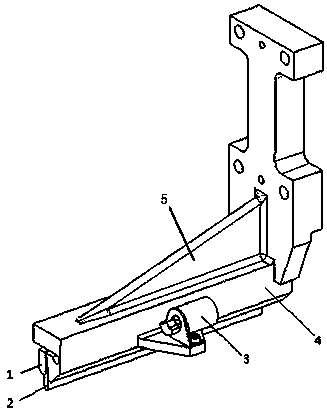

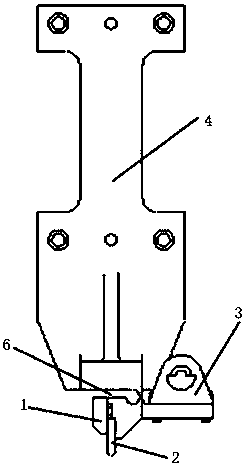

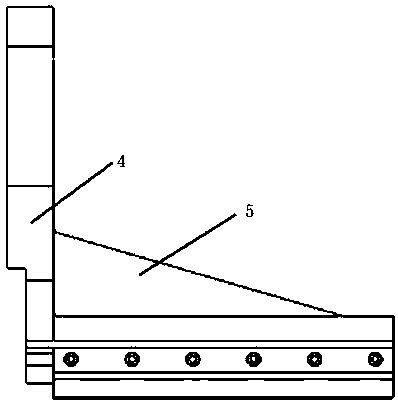

[0029] see Figure 1-3 , a vibrating powder spreading device for laser selective melting and forming equipment, including a pressing plate 1, a scraper 2, a scraper seat 4 and a vibration motor 3, the scraper 2 is fixed on the scraper seat 4 through the pressing plate 1 and screws, and the scraper seat 4 It is an elastic structure, the vibration motor 3 is fixed to the scraper seat 4 by screws, and the axis of the vibration motor 3 is kept parallel to the scraper 2 and the working plane;

[0030] Such as image 3 As shown, the scraper seat 4 is L-shaped as a whole, with triangular reinforcing ribs 5 at the corners. The scraper seat 4 is processed with a hollow channel 6 in the area above the installation position of the scraper 2. The exterior of the channel 6 is in the shape of a rectangular slit. It is in the shape of a round hole, and only a very narrow part of the connection area is reserved in the cross section, forming an elastic deformation area, that is, the bending d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com