Square pile wire cutting device and mechanical excavation method of hard rock stratum square pile

A square pile and wire cutting technology, applied in drilling equipment and methods, drilling equipment, stone processing equipment, etc., can solve the problems of high dependence on operation level and objective conditions, poor stability of construction quality and low construction efficiency, etc. To achieve the effect of reducing dependence, stable construction quality and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

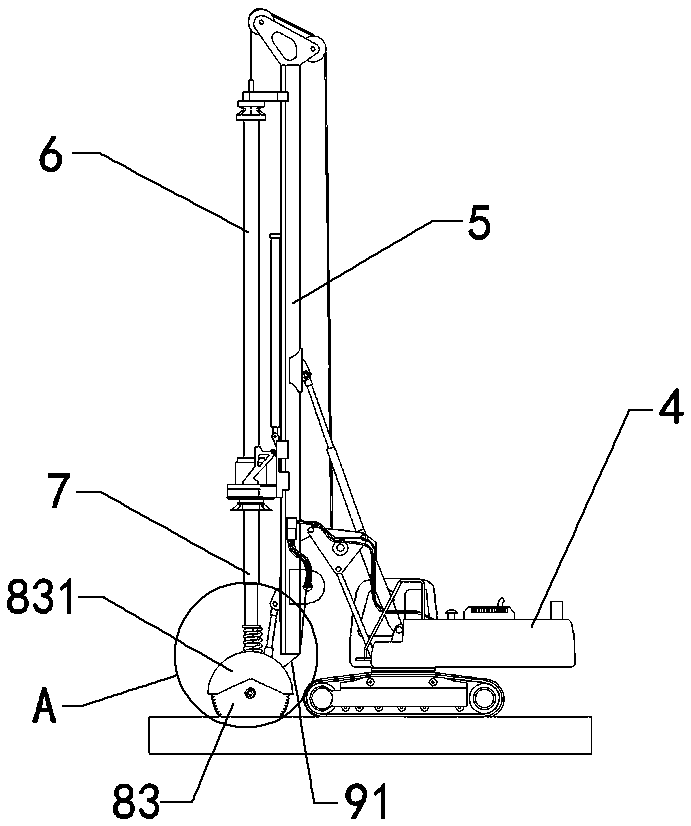

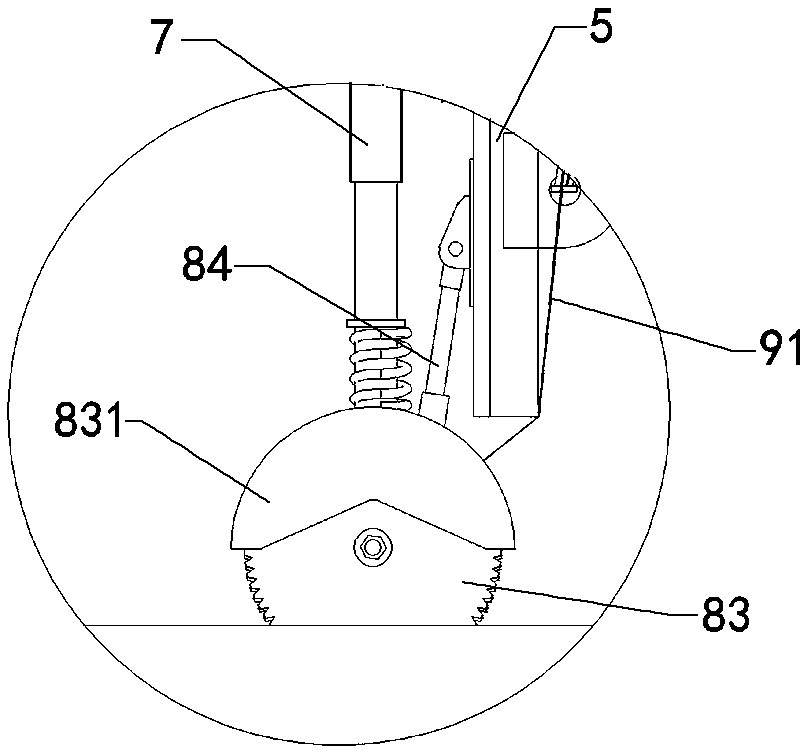

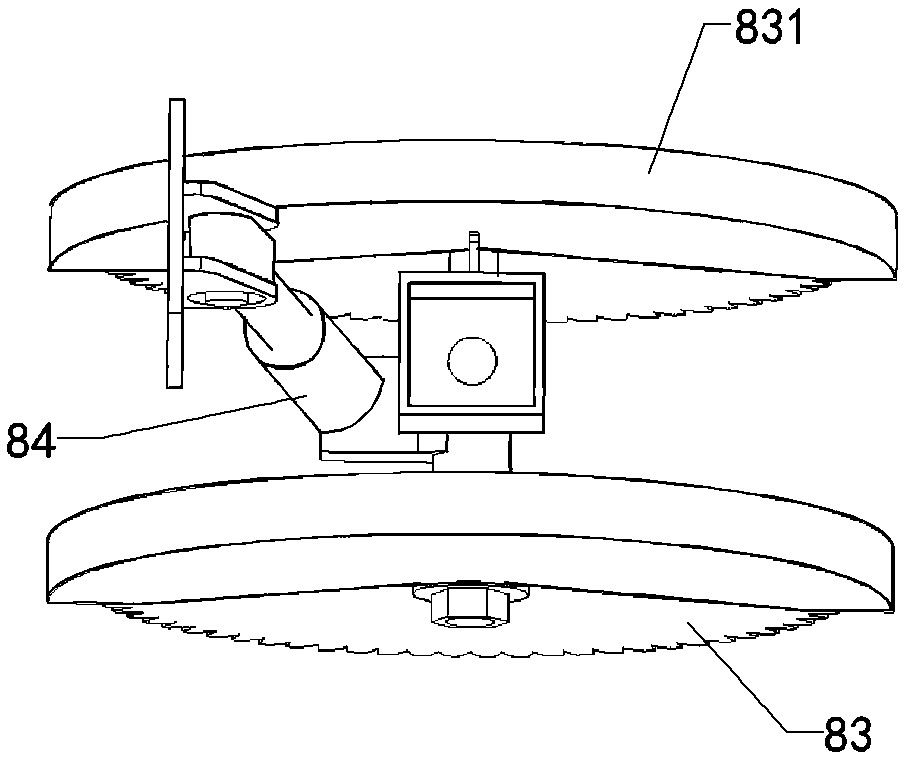

[0036] Such as Figure 6 Shown, the mechanical excavation method of square pile in hard rock formation of the present invention may further comprise the steps:

[0037] Step 1. Site leveling: clean up and level the construction site;

[0038] Step 2. Measurement and setting out: According to the construction plan, determine the position of the square pile to be constructed, perform accurate measurement and setting out, and mark the central axis and the construction point of the circular pile hole 2;

[0039] Step 3, circular pile hole construction: use a rotary excavator to excavate a circular pile hole 2 in the middle of the square pile until the design depth of the pile hole; the diameter of the circular pile hole 2 is 600-2500mm, and the circular pile hole 2 When the number of circular pile holes 2 is 1, the central axis of the circular pile hole 2 coincides with the central axis of the square pile hole 1. The axis L1 of the cross-section is arranged side by side, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com