Preparation method of edible-fungus liquid strain culture medium

A technology of liquid strains and culture medium, applied in botany equipment and methods, liquid fertilizers, applications, etc., can solve the problems of insoluble natural organic components, different sterilization effects, pollution and scrapping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0021] Embodiment 1-3: mushroom cultivation

[0022] The culture medium of embodiment 1-3 is as shown in table 1

[0023] The medium component of table 1 embodiment 1-3

[0024]

[0025] The preparation method of embodiment 1-3 comprises the following steps,

[0026] (1) Heat the water in the fermenter to 100°C for 1.5 hours;

[0027] (2) Drain the heated water in step (1) into the mixer, and add the culture medium while stirring, the stirring speed is 200rpm, and the duration of the whole process is 15min; the volume ratio of culture medium and water is 1:50.

[0028] (3) The liquid culture medium obtained in step (2) is sterilized at 123°C with a pressure of 0.123MPa;

[0029] (4) Cool to room temperature.

[0030] (5) Inoculate hair bacteria by conventional methods.

Embodiment 2

[0034] The full bag time of Example 2 was 3 days earlier than that of Comparative Example 2, and the biotransformation rate was 7.6 percentage points higher.

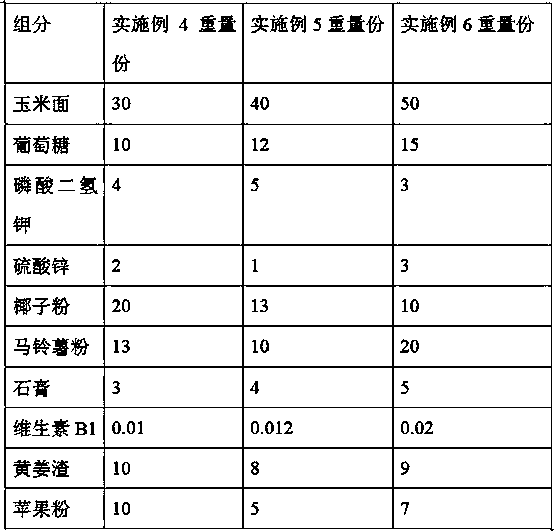

Embodiment 4-6

[0035] Embodiment 4-6: Pleurotus eryngii cultivation

[0036] The culture medium of embodiment 4-6 is as shown in table 2

[0037] The medium component of table 2 embodiment 4-6

[0038]

[0039] The preparation method of embodiment 4-6 comprises the following steps,

[0040] (1) Heat the water in the fermenter to above 90°C, which is 93°C in this example, and keep it for 2 hours;

[0041] (2) Drain the heated water in step (1) into the mixer, add the culture medium while stirring, the stirring speed is 250rpm, and the duration of the whole process is 23min; the volume ratio of culture medium and water is 1:55.

[0042] (3) The liquid culture medium obtained in step (2) is sterilized at 122°C, and the sterilization pressure is 0.12 MPa;

[0043] (4) Cool to room temperature.

[0044] (5) Inoculate hair bacteria by conventional methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com