Pre-reaction liquid for chlorinated rubber adhesive and preparation method of pre-reaction liquid

A technology of chlorinated rubber and adhesives, which is applied in the direction of halogen rubber derivative adhesives, adhesives, adhesive types, etc., and can solve problems such as solid-liquid delamination that is not easy to occur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

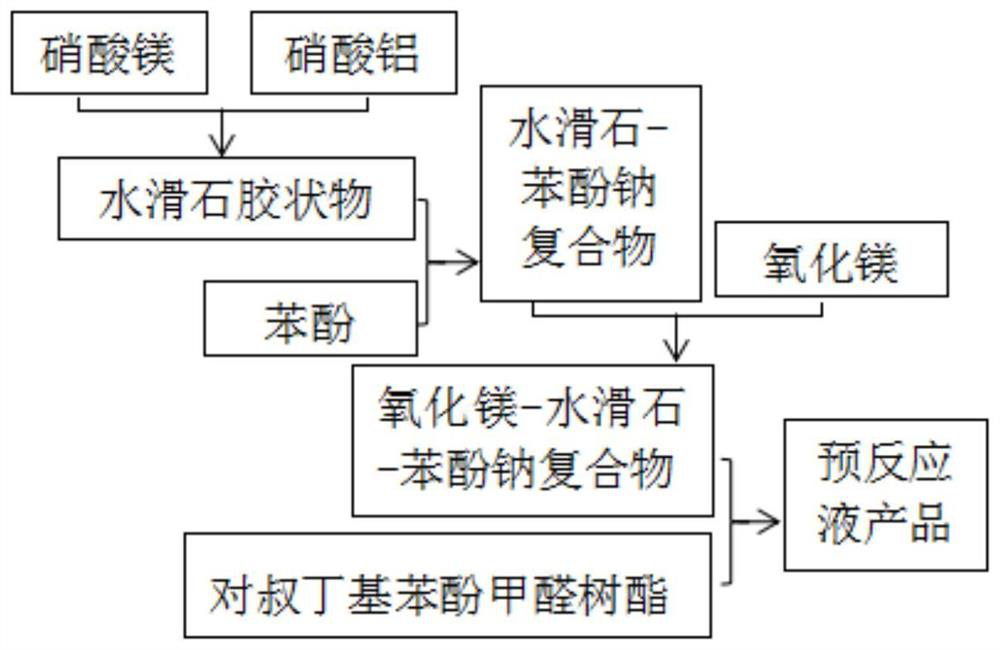

[0030] A kind of pre-reaction solution for chlorinated rubber adhesive, its preparation steps are as follows:

[0031] (1) At room temperature, aluminum nitrate nonahydrate, magnesium nitrate hexahydrate and distilled water from carbon dioxide removal are mixed and stirred, and the resulting mixed solution is adjusted to pH 7.0 with lye at a stirring condition of 100 r / min, and then mixed under nitrogen protection and React for 0.5h under the stirring condition of rotating speed of 500r / min, place the obtained mixture in a closed reaction kettle and react for 2h at 70°C, filter the obtained mixture, and wash with distilled water to remove carbon dioxide until the filtrate is neutral, and the filtered gel The material is for standby; the lye described in the step (1) adopts 5wt% NaOH solution, and the weight ratio of magnesium nitrate hexahydrate, aluminum nitrate nonahydrate and the water that removes carbon dioxide is 1:0.32:15 in the step (1);

[0032] (2) Mix the jelly obta...

Embodiment 2

[0036] A kind of pre-reaction solution for chlorinated rubber adhesive, its preparation steps are as follows:

[0037] (1) At room temperature, aluminum nitrate nonahydrate, magnesium nitrate hexahydrate and distilled water from carbon dioxide removal are mixed and stirred, and the resulting mixed solution is adjusted to pH 8.0 with lye under the stirring condition of 300r / min at a rotating speed, and then mixed under nitrogen protection and React for 1 h under the stirring condition of 700 r / min, place the obtained mixture in a closed reaction kettle and react for 7 h at 80°C, filter the obtained mixture, and wash with distilled water to remove carbon dioxide until the filtrate is neutral, and the filtered jelly Standby; the lye described in the step (1) adopts 10wt% NaOH solution, and the weight ratio of magnesium nitrate hexahydrate, aluminum nitrate nonahydrate and the water for removing carbon dioxide in the step (1) is 1.02:0.34:18;

[0038] (2) Mix the jelly obtained in...

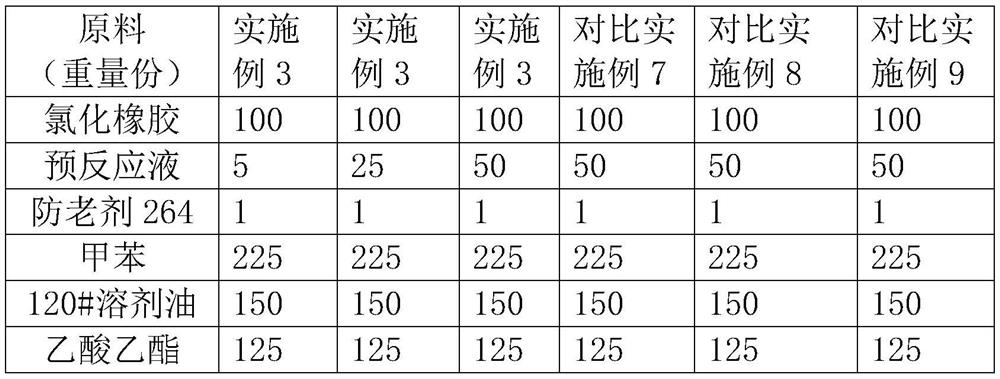

Embodiment 3

[0042] A kind of pre-reaction solution for chlorinated rubber adhesive, its preparation steps are as follows:

[0043] (1) At room temperature, aluminum nitrate nonahydrate, magnesium nitrate hexahydrate, and distilled water for removing carbon dioxide are mixed and stirred, and the resulting mixed solution is adjusted to pH 9.5 with lye under the stirring condition of 550r / min at a rotating speed, and then mixed under nitrogen protection and React for 2 hours under stirring conditions with a rotation speed of 1000r / min. The obtained mixture is placed in a closed reactor and reacted for 24 hours at 100°C. The obtained mixture is filtered and washed with distilled water to remove carbon dioxide until the filtrate is neutral. The filtered jelly Standby; the lye described in the step (1) adopts 15wt% NaOH solution, and the weight ratio of magnesium nitrate hexahydrate, aluminum nitrate nonahydrate and the water for removing carbon dioxide in the step (1) is 1.04:0.37:22;

[0044]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com