Novel advertising film with porous adhesive layer structure

An adhesive layer and advertising technology, applied in the directions of adhesives, adhesive types, natural rubber adhesives, etc., can solve the problems of poor environmental protection, insufficient exhaust, and high energy consumption, and achieve easy posting and suitable preparation process. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

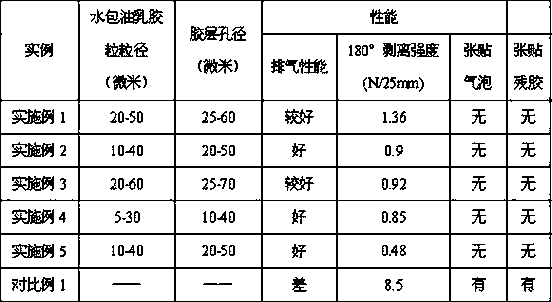

Embodiment 1

[0025] Add 15 parts of toluene, 1.2 parts of sorbitan laurate and 0.3 parts of sodium lauryl sulfate into the dispersion tank, stir and mix for 10 minutes, then add 36 parts of deionized water and 0.02 parts of polyether modified silicone defoamer , and control the adding speed of water and stirring speed until the phase inversion of the system occurs to form a uniform emulsion. Then, 25 parts of pure acrylic emulsion, 20 parts of self-crosslinking styrene-butadiene latex, 0.3 parts of ammonia water, 1 part of carboxymethyl cellulose solution and 0.7 parts of polyacrylate thickener were sequentially added to the emulsion. Finally, the emulsion is coated on the polypropylene film, and the thickness of the porous adhesive layer is 100 microns. After heating at 80-130°C for 10 minutes, the polypropylene release film is covered to obtain a new advertising film with a porous adhesive layer structure.

Embodiment 2

[0027] Add 15 parts of cyclohexane, 0.9 parts of sorbitan laurate and 1.1 parts of sodium oleate into the dispersion tank, stir and mix for 10 minutes, then add 36 parts of deionized water and 0.02 parts of polyether modified silicone defoaming agent, and control the adding speed of water and stirring speed until the phase inversion of the system occurs to form a uniform emulsion. Then, 25 parts of pure acrylic emulsion, 20 parts of self-crosslinking styrene-butadiene latex, 0.3 parts of ammonia water, 1 part of carboxymethyl cellulose solution and 0.7 parts of polyacrylate thickener were sequentially added to the emulsion. Finally, the emulsion is coated on the polypropylene film, and the thickness of the porous adhesive layer is 100 microns. After heating at 80-130°C for 10 minutes, the polypropylene release film is covered to obtain a new advertising film with a porous adhesive layer structure.

Embodiment 3

[0029] Add 15 parts of toluene, 1.2 parts of sorbitan laurate and 0.3 part of sodium lauryl sulfate into the dispersion tank, stir and mix for 10 minutes, then add 36 parts of deionized water and 0.01 part of polyether modified silicone defoamer , and control the adding speed of water and stirring speed until the phase inversion of the system occurs to form a uniform emulsion. Then, 15 parts of water-soluble polyacrylate, 10 parts of polyvinyl ether, 20 parts of natural latex, 0.3 part of ammonia water, 1 part of hydroxyethyl cellulose solution and 1 part of polyacrylate thickener were sequentially added to the emulsion. Finally, the emulsion is coated on the polyester film, and the thickness of the porous adhesive layer is 100 microns. After heating at 80-130°C for 10 minutes, the polyester release film is covered to obtain a new type of advertising film with a porous adhesive layer structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com