Horizontal alloy ingot preheating charging machine

An alloy ingot and feeder technology is applied in metal processing equipment, equipment for feeding molten metal into casting molds, casting equipment, etc. problems such as large land area, to achieve the effect of reducing manufacturing cost and complexity, occupying less space and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

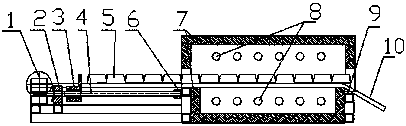

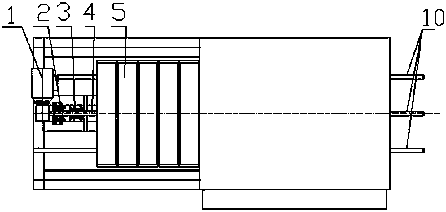

[0016] Taking the magnesium alloy die-casting furnace magnesium ingot feeder as an example, the figure 1 , figure 2 A schematic diagram of a horizontal alloy ingot preheating feeder is shown for further explanation:

[0017] When magnesium alloy die-casting is produced in a cold chamber, five magnesium alloy ingots are manually added to the guide rail (10) at the left end of the heat preservation cover (7) at one time, and the reducer (1) works, driving and installed on the driving screw (4). The push plate (3) moves to the right, the reducer (1) works intermittently, and continues to push the magnesium alloy ingot to the left until the magnesium alloy ingot on the guide rail (10) is pushed to the sloped position of the guide rail (10), Under the action of its own potential energy, the magnesium alloy ingot slides down the slope guide rail and slides into the feeding port of the magnesium alloy melting furnace, thereby completing a feeding action. During the whole feeding pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com