Method for extracting naphthalin from heavy C10 aromatic solvent oil by integral device

An aromatic solvent oil and heavy technology, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the problems of complex processing, difficult crystallization temperature control, unfavorable naphthalene refining, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

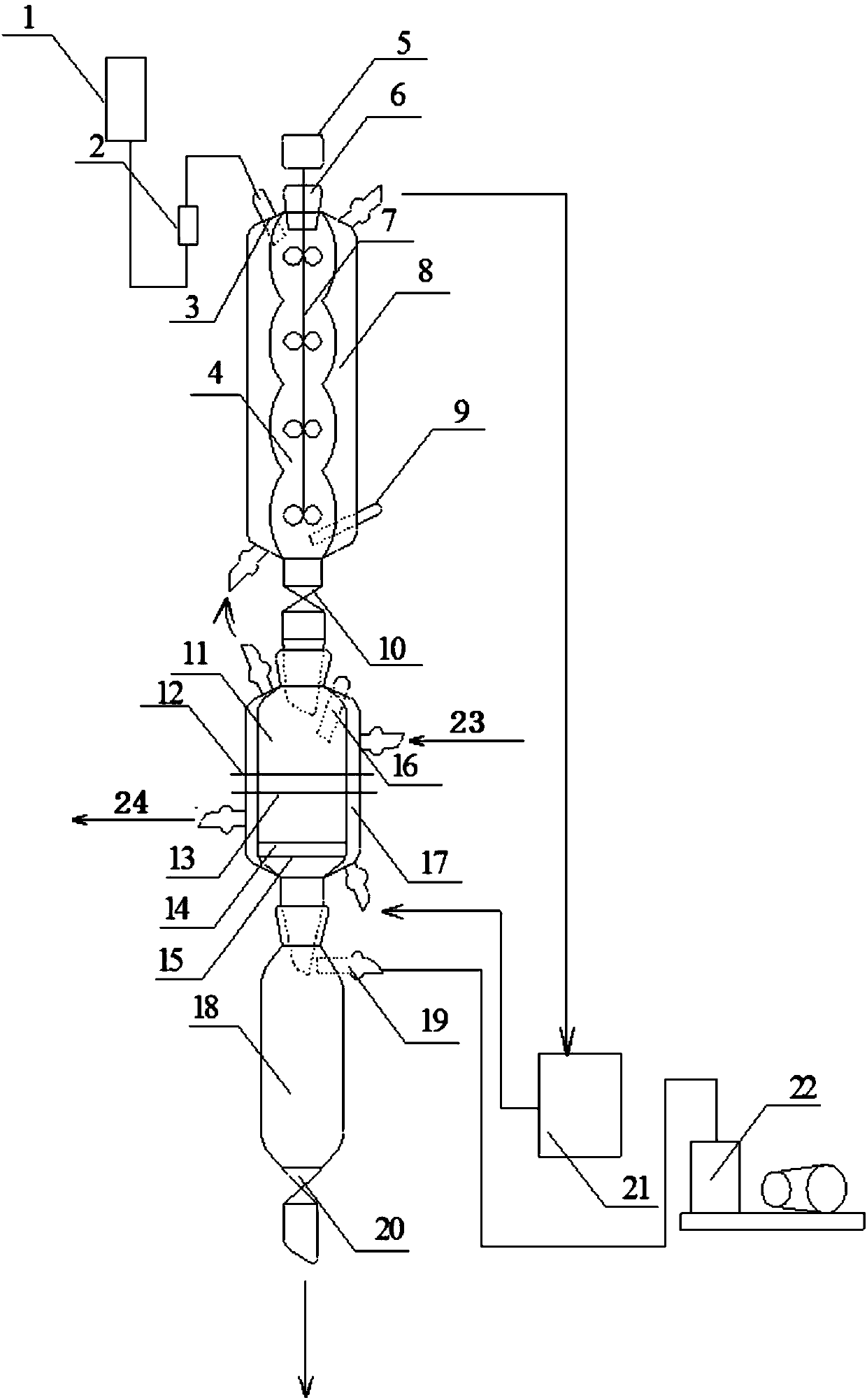

[0023] Integrated device in the inventive method, its result is as figure 1 As shown, it includes a multi-stage axially stirred crystallizer device, a filter device and a collection device 18;

[0024] The upper end of the filter device is connected to the multi-stage axial stirring crystallizer device, the lower end is connected to the collection device 18, and the upper grinding port 12 and the lower grinding port 13 are provided in the middle, which can separate the upper and lower parts of the filter device. Plate 15, the surface of filter plate 15 is covered with filter paper 14;

[0025] The multi-stage axial stirring crystallizer device includes a stirring shaft 7 inside it, the upper end of which passes through the opening of the device and is connected to the driving device 5, and a first jacket 8 inside it, which isolates its internal space into a stirring shaft The space where 7 is located and the constant temperature medium passes through the space, and the feed p...

Embodiment 2

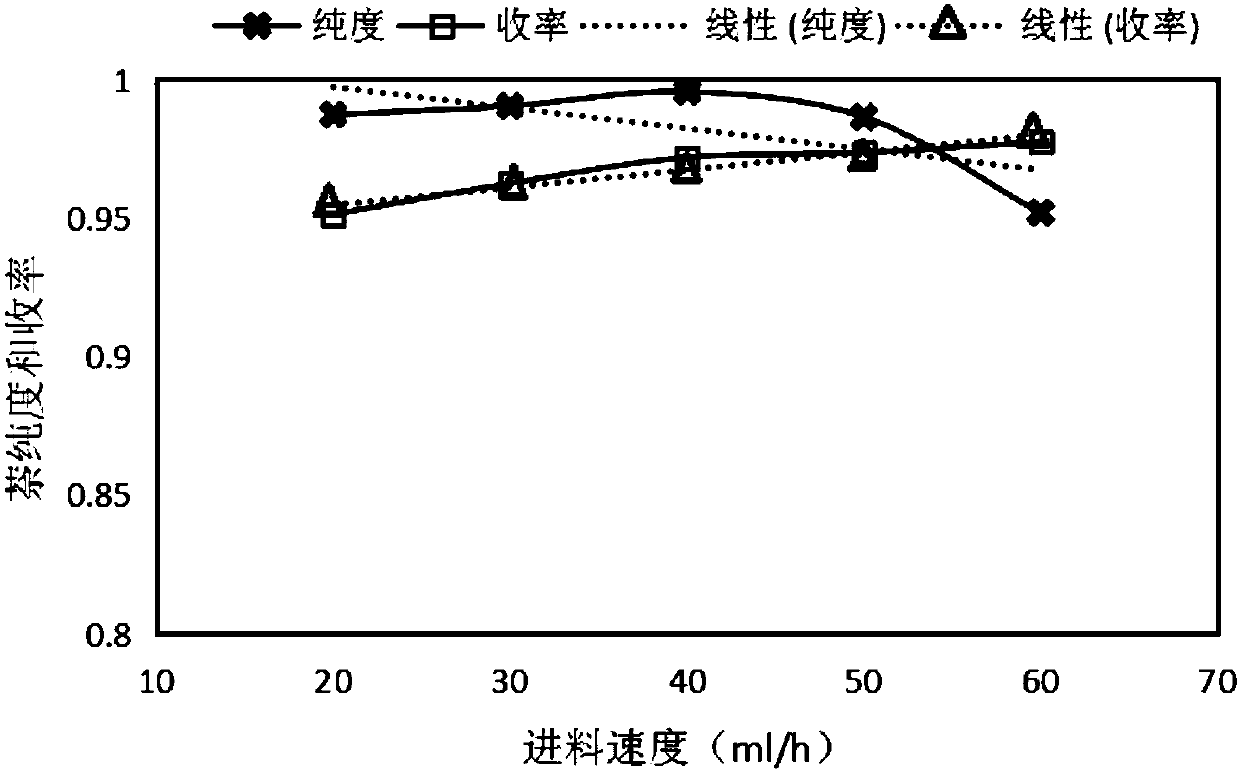

[0039] Utilize above-mentioned integrated device to extract the method for naphthalene in heavy C10 aromatic solvent oil:

[0040] According to the operating method of the above-mentioned device, the raw material heavy C 10 Aromatic solvent oil (the naphthalene content is about 43%, and the remaining composition is shown in Table 1) is added from the feed port, the feed speed and the rotating speed of the stirring shaft are controlled, the crystallization and filtration are controlled to the same temperature by a constant temperature medium, and the filter device is vacuumed In a vacuum state, the raw material flows downward from the multi-stage axially stirred crystallizer device into the filter device, vacuum filtration is carried out in the filter device, and finally the filtrate is collected through the collection device, and the filter cake is collected through the filter device, and the obtained filter cake is The extracted naphthalene.

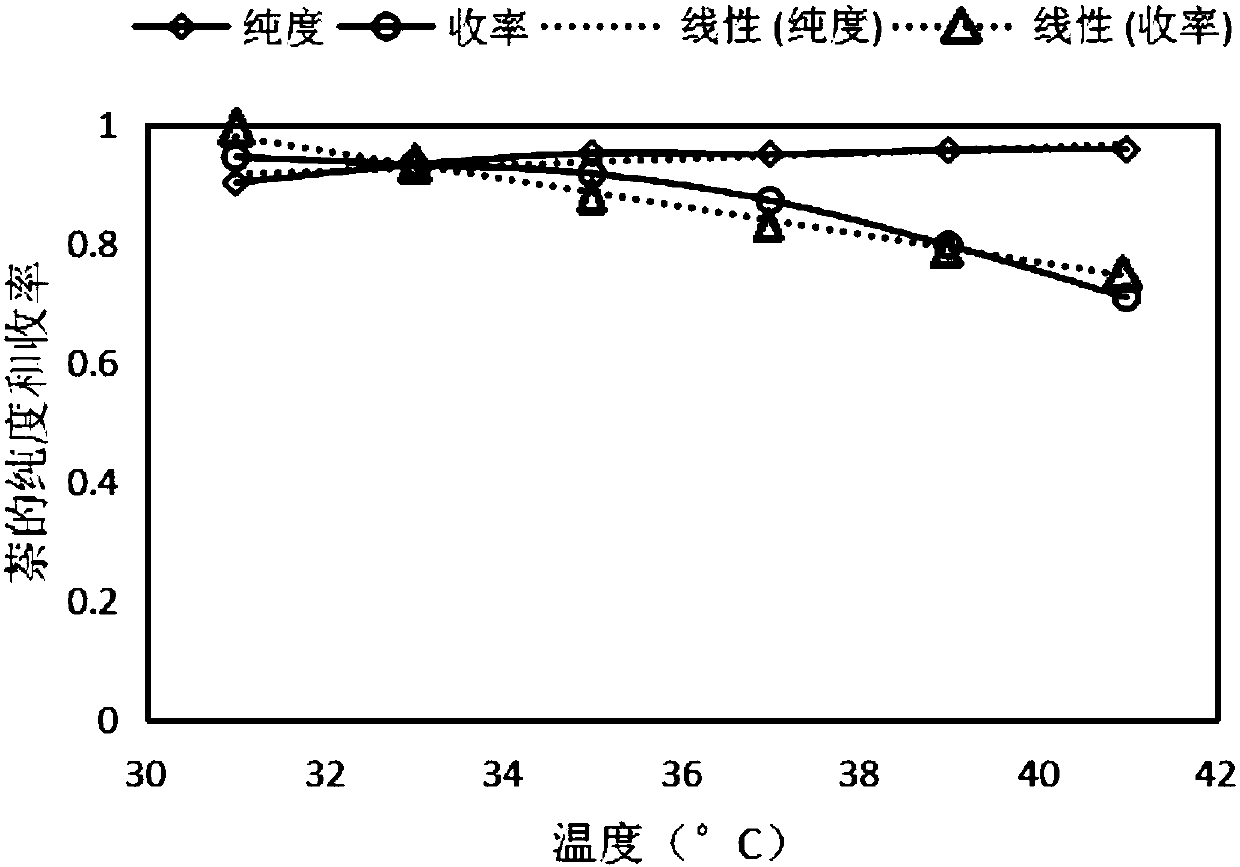

[0041] In the method, the feed ...

Embodiment 3

[0059] Device and method are with embodiment 1 and embodiment 2, and difference only is as follows:

[0060] The feed rate is 20ml / h, the rotation speed is 40rpm, and the crystallization and filtration temperature is 30-31°C.

[0061] The final naphthalene content and yield reached 98.75% and 96.33%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com