Improving method for stirring practicability of rear reaction tank of first brine system

A reaction tank, a practical technology, applied in chemical instruments and methods, chemical/physical/physical chemical fixed reactors, mixers, etc., can solve the problem of excessive calcium ion in brine, frequent maintenance, and insufficient reaction of sodium carbonate and calcium chloride Complete and other problems, to extend the response time, to ensure the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The technical problem to be solved by the present invention adopts the following technical solutions to realize:

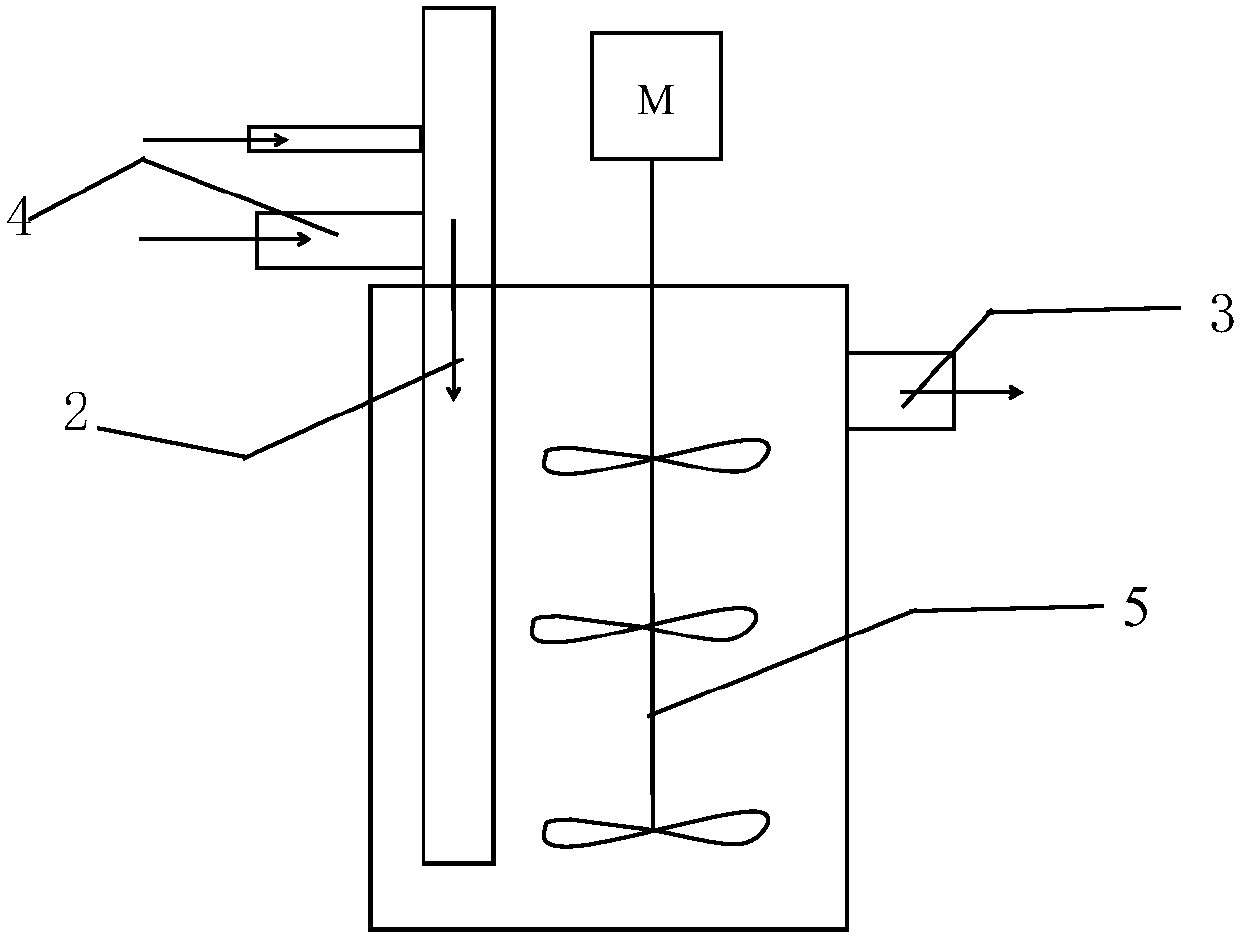

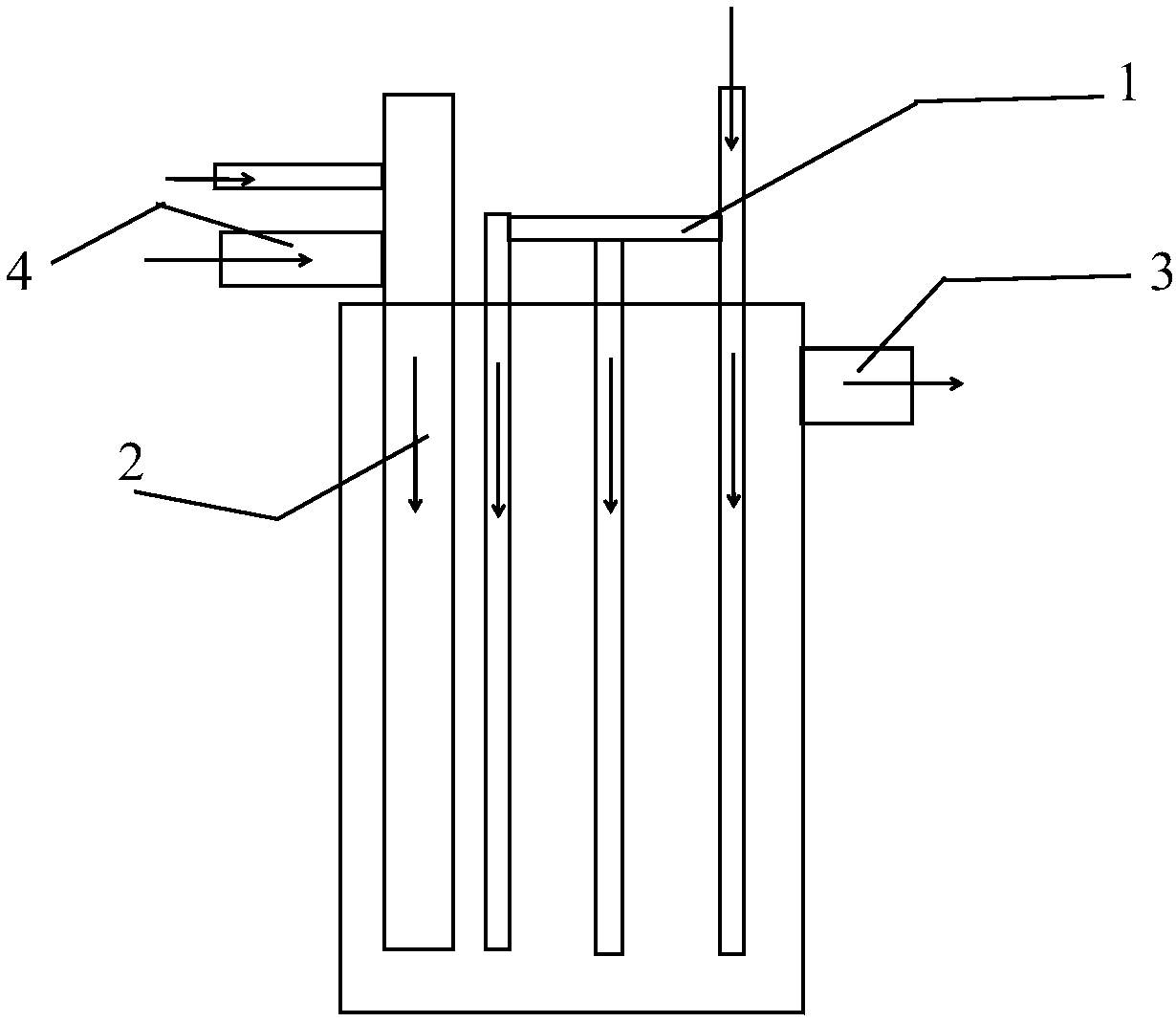

[0027] Such as figure 1 and 2 as shown, figure 1 The stirring paddle in the original mechanical stirring device of the rear reaction tank is changed to figure 2 Compressed gas aeration, three DN25 pipes; post-reaction tank compressed gas aeration device includes: 1--compressed gas aeration pipe; 2--feeding pipe; 3--exhaust port; 4--feeding port;

[0028] The 4-feed inlet is connected with the 2-feed pipeline, and the lower inlet in the feed inlet is the crude brine inlet; the upper feed inlet is the refined preparation sodium carbonate inlet;

[0029] The 2-feed pipeline is connected with the rear reaction tank, and the feed pipeline enters the tank body from the upper surface of the rear reaction tank;

[0030] The 1--compressed air aeration pipe has a main pipe that is input from the compressed air end near the reaction tank end, and then divided int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com