Driving circuit with high speed and large output swing

A technology of driving circuits and large output, applied in amplifiers, electrical components, and improving amplifiers to expand bandwidth, etc., can solve the problems of inability to adapt to the overall performance of the circuit, passive inductors occupy a large area, and increase the cost of chip manufacturing, so as to save chips. area, improved linearity, increased gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

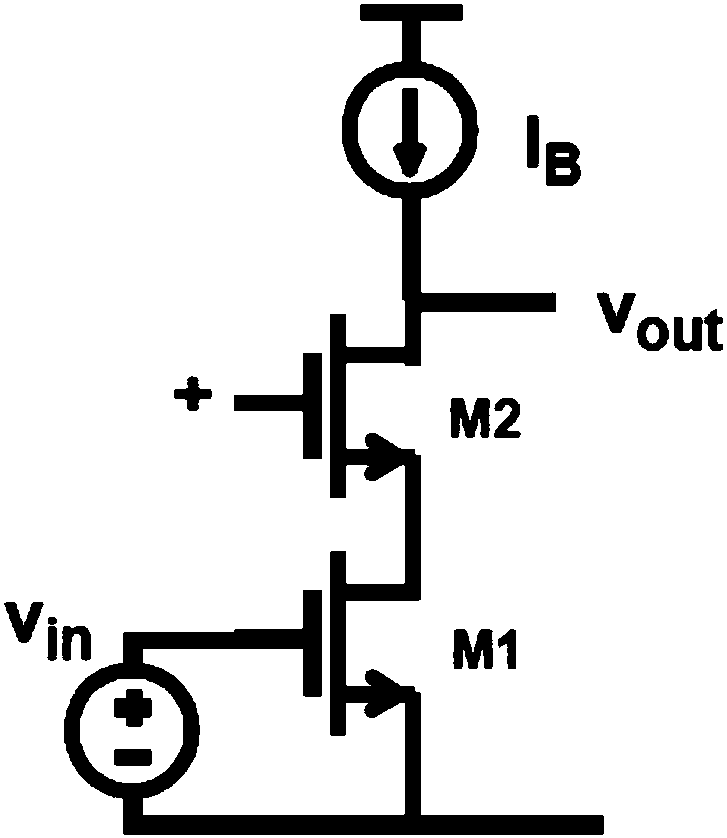

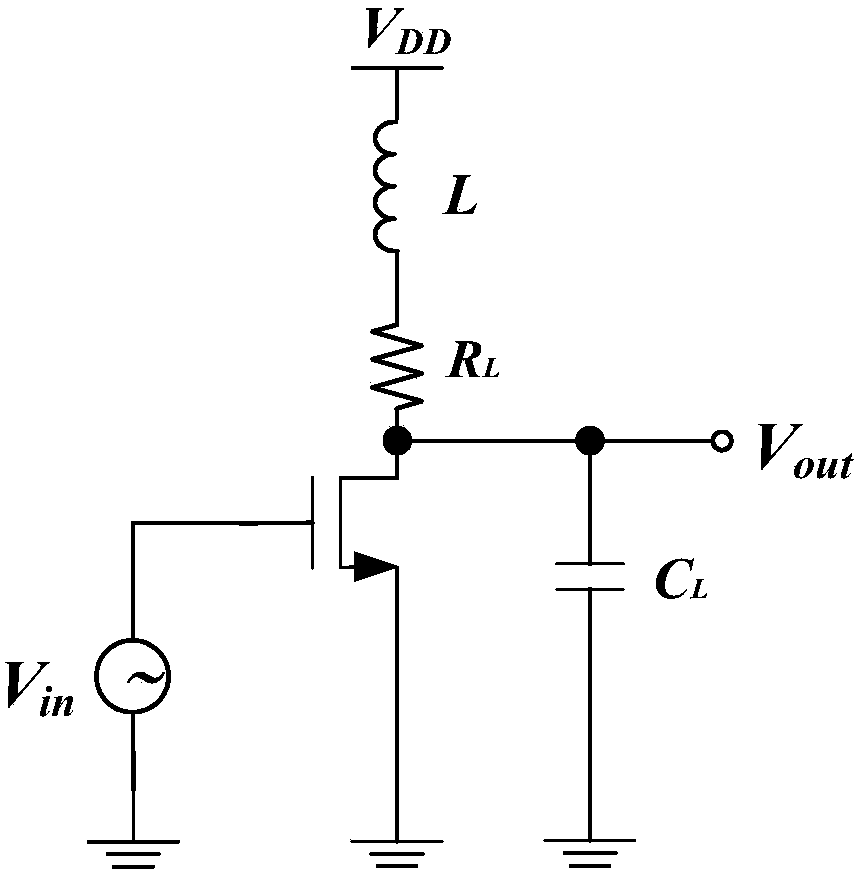

[0047] The specific embodiment of a high-speed large output swing driving circuit of the present invention will be further described below in conjunction with the accompanying drawings: refer to the attached Figure 4 , the present invention is a high-speed large output swing drive circuit, including: a first-stage emitter follower circuit for level shift and impedance matching, a second-stage differential structure for amplifying input signals and providing sufficient bandwidth common emitter amplifier circuit. The first-stage emitter follower circuit includes: an emitter follower composed of Q1 and Q2, impedance matching resistors R1 and R2; also includes: a bias current source for Q1 and Q2, and the bias current source is connected by a diode M1 / M4 and cross-coupled M2 / M3 parallel structures; the emitter follower is used to reduce the DC level of the input signal to a value that can be directly processed by the internal circuit.

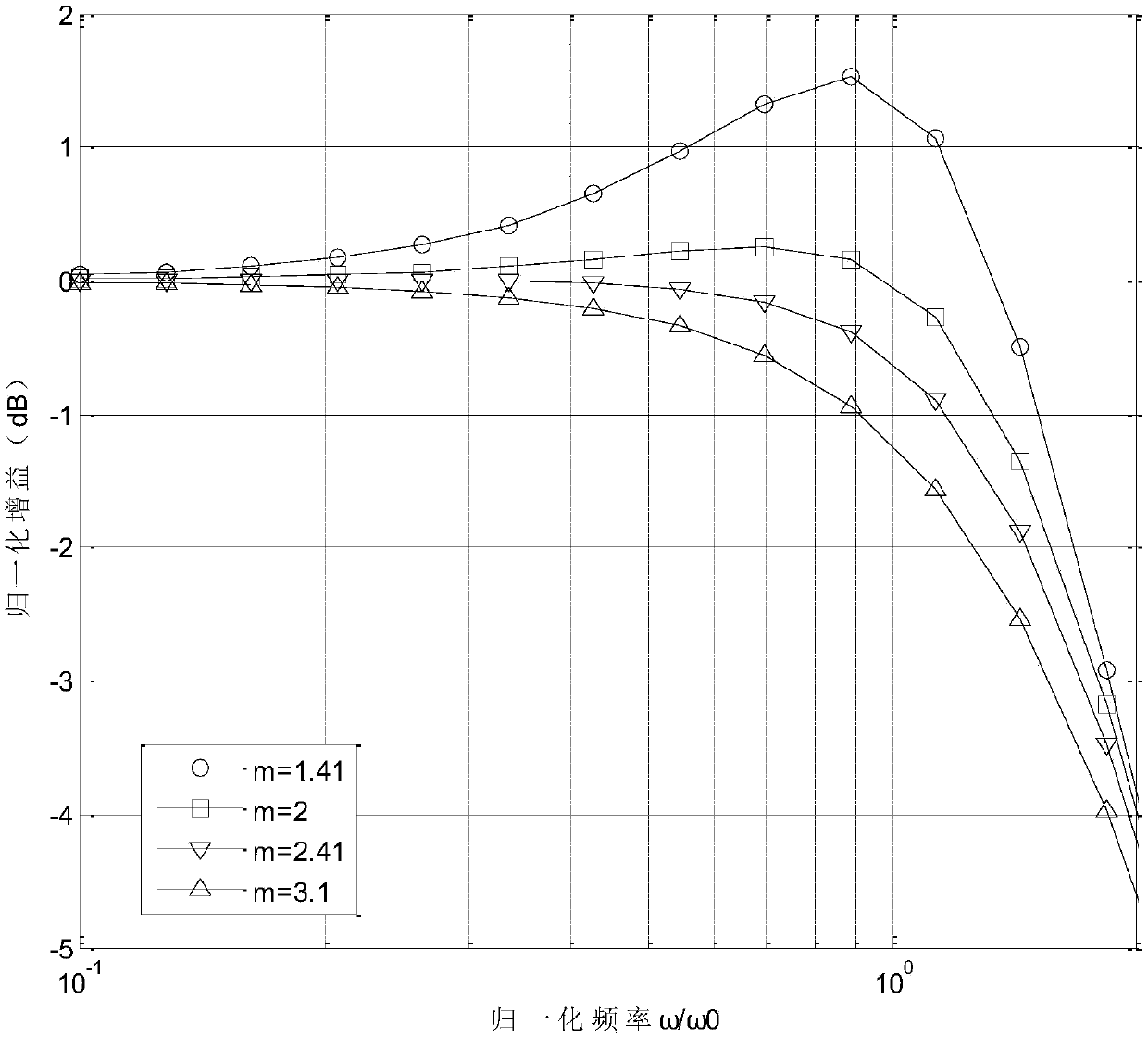

[0048] The second-stage differential struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com