Drum grille and using method thereof

A drum grid and drum technology, which is applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of higher requirements for civil engineering basic conditions, increased energy consumption for sewage treatment, and unfavorable discharge of fine impurities, so as to ensure the anti-reverse effect. Flushing effect, easy installation, reducing mechanical vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

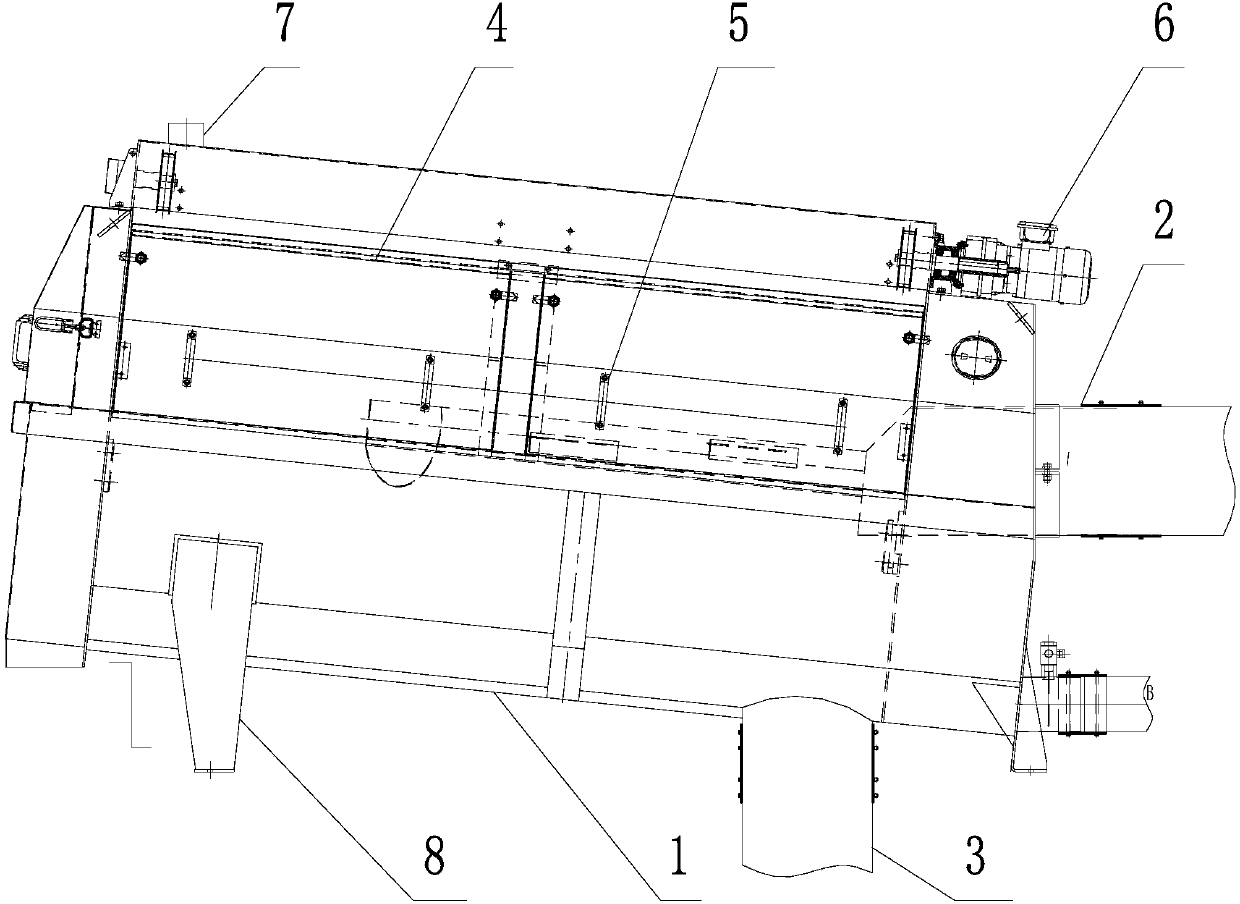

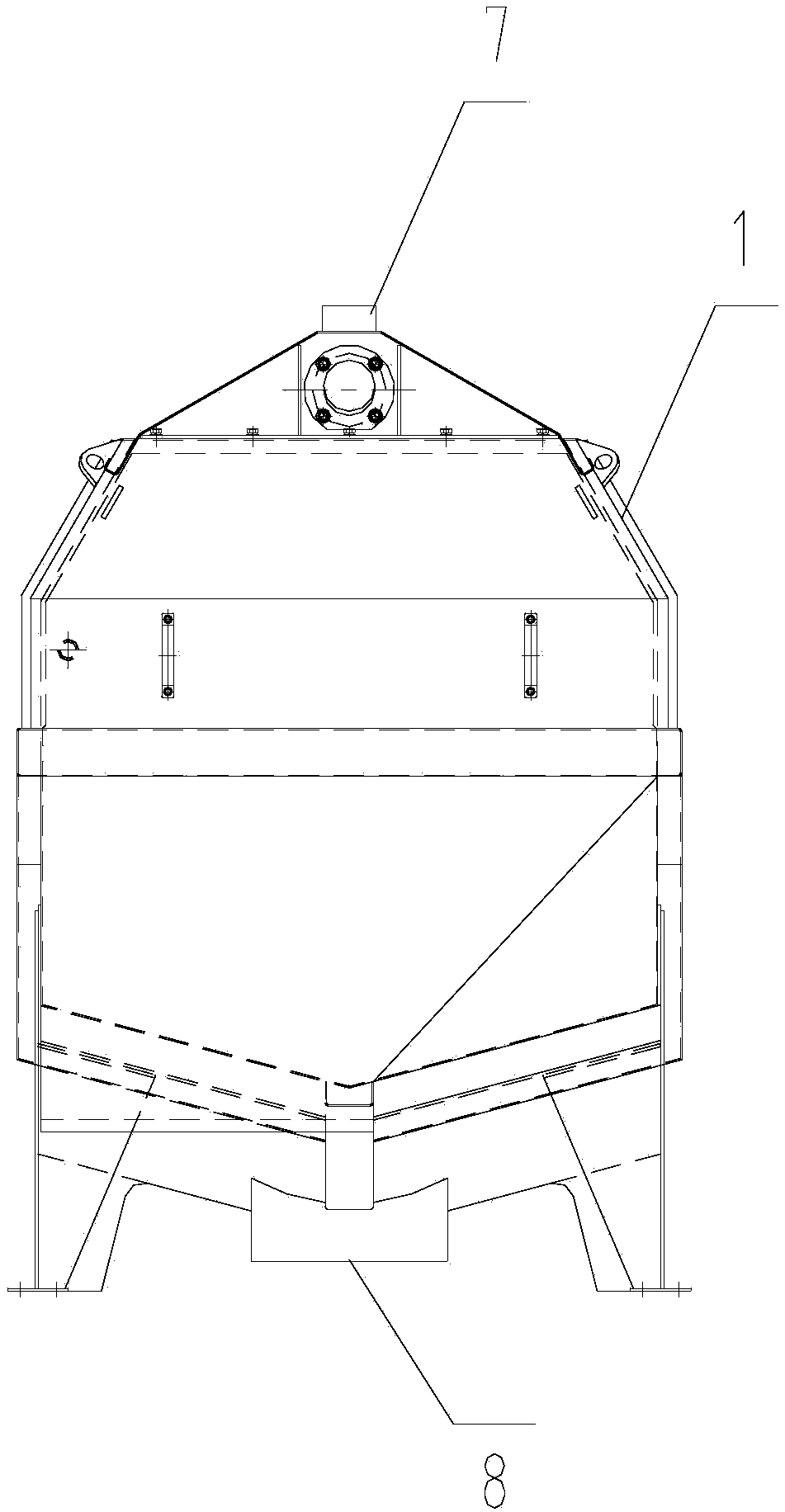

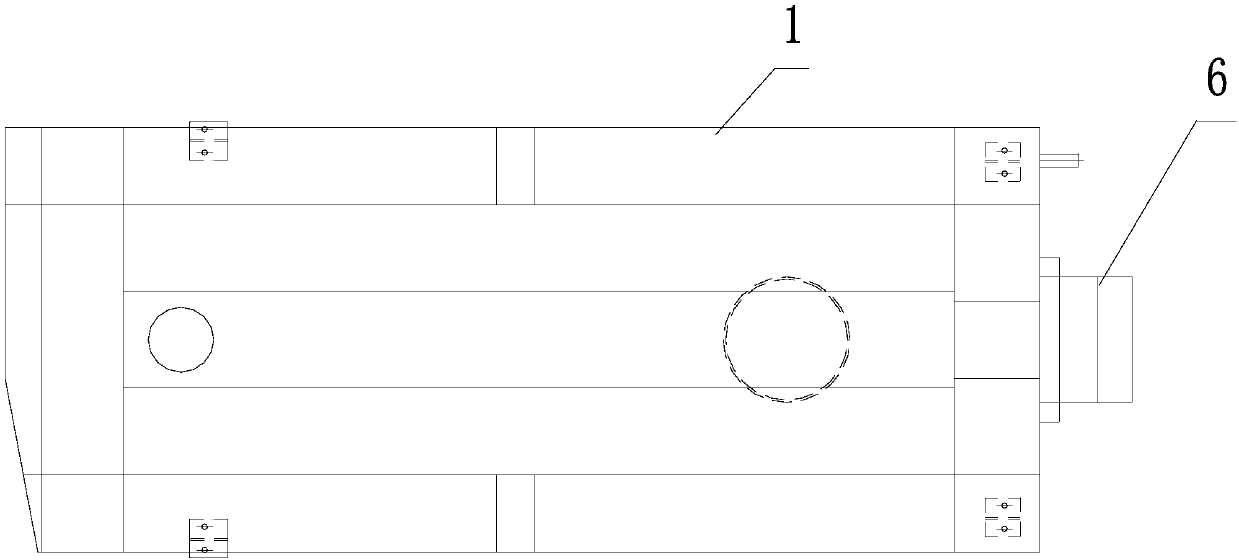

[0028] Attached below Figure 1-3 The roller grill of the present invention and its application method are described in detail.

[0029]A kind of roller grill, the roller grill includes a shell 1 and a support frame arranged at the bottom of the shell, the left end of the shell is provided with a sewage water inlet 2, and the bottom of the shell is provided with a drain 3; There are roller assembly 4 and brush assembly 5. The roller assembly is placed horizontally in the shell of the shell. The roller assembly includes a cylindrical roller screen and a roller shaft. The drum shaft is fixedly arranged on the left and right ends of the drum screen. The brush assembly is arranged on the inner wall of the roller screen for cleaning the inner wall of the roller screen; the brush assembly includes a brush and a brush shaft, and the brush shaft is fixedly arranged on the ends of the left and right sides of the brush The sewage water inlet is connected to the water inlet distribution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com