Bismuth oxychlorobromide (010)/graphene heterojunction, and preparation method and application thereof

A kind of technology of bismuth oxychlorobromide and bismuth oxybromide, applied in the field of bismuth oxychlorobromide/graphene heterojunction and preparation thereof, can solve the problem that no report, no patent and literature report bismuth oxychlorobromide (010)/graphite The preparation method and application of ene heterojunction, etc., to achieve the effects of low cost, improved photocatalytic performance, and easy size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

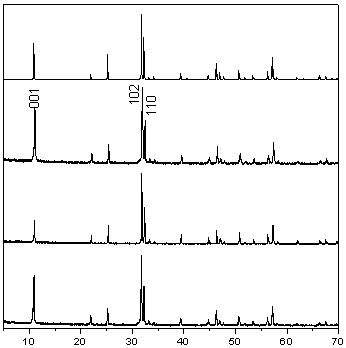

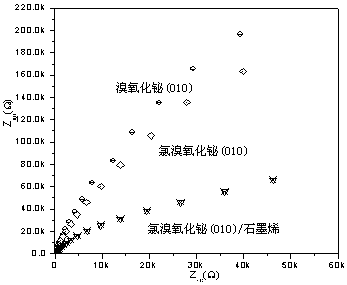

Method used

Image

Examples

Embodiment 1

[0037] Step 1, take 0.050g of commercial graphene and add it into deionized water, ultrasonically disperse at 30°C for 15min, the ultrasonic power is 65W, and then continue to stir for 35min to make A liquid;

[0038] Step 2, 5mmol of Bi(NO 3 ) 3 ·5H 2 O was added to 2.0 mol / L HNO 3 , stirred at 70°C until completely dissolved, and the stirring time was 60 minutes, and made into liquid B;

[0039] Step 3, take 4.95mmol KBr and 0.05mmol KCl and dissolve in deionized water to make C solution, wherein Bi(NO 3 ) 3 ·5H 2 The molar ratio of O to (KBr+KCl) is 1:1;

[0040] Step 4: Slowly add the prepared liquid A to liquid B dropwise at a rate of 14 drops / min, and stir while adding. After the dropwise addition, ultrasonically disperse at 30°C with a power of 65W for 20 minutes, and then stir for 30 minutes. into D liquid;

[0041] Step 5, slowly drop 2.0 mol / L NaOH solution into D liquid at a rate of 14 drops / min, adjust the pH value of D liquid to 6, and continue stirring fo...

Embodiment 2

[0046] Step 1: Add 0.055g of commercial graphene into deionized water, ultrasonically disperse at 35°C for 20min, the ultrasonic power is 70W, and then continue to stir for 40min to make A solution;

[0047] Step 2, 5mmol of Bi(NO 3 ) 3 ·5H 2 O was added to 2.5 mol / L HNO 3 , stirred at 75°C until completely dissolved, and the stirring time was 65 minutes, and made into liquid B;

[0048] Step 3, take 4.90mmol KBr and 0.10mmol KCl and dissolve in deionized water to make C solution, wherein Bi(NO 3 ) 3 ·5H 2 The molar ratio of O to (KBr+KCl) is 1:1;

[0049] Step 4: Slowly add the prepared liquid A to liquid B dropwise at a rate of 12 drops / min. Stir while adding. After the dropwise addition, ultrasonically disperse at 35°C with a power of 70W for 20 minutes, and then stir for 35 minutes. into D liquid;

[0050] Step 5, slowly drop 2.5 mol / L NaOH solution into D liquid at a rate of 12 drops / min, adjust the pH value of D liquid to 6, and continue stirring for 25 min;

[...

Embodiment 3

[0055] Step 1, take 0.060g of commercial graphene and add it into deionized water, ultrasonically disperse at 40°C for 20min, the ultrasonic power is 75W, and then continue to stir for 45min to make A liquid;

[0056] Step 2, 5mmol of Bi(NO 3 ) 3 ·5H 2 O was added to 3.0 mol / L HNO 3 , stirred at 80°C until completely dissolved, and the stirring time was 70 minutes, and made into B liquid;

[0057] Step 3, take 4.85mmolKBr and 0.15mmol KCl and dissolve in deionized water, and make C solution, wherein Bi(NO 3 ) 3 ·5H 2 The molar ratio of O to (KBr+KCl) is 1:1;

[0058] Step 4: Slowly add the prepared liquid A to liquid B dropwise at a rate of 10 drops / min. Stir while adding. After the dropwise addition, ultrasonically disperse at 40°C with a power of 75W for 25 minutes, and then stir for 40 minutes. into D liquid;

[0059] Step 5, slowly drop 2.5 mol / L NaOH solution into D liquid at a rate of 10 drops / min, adjust the pH value of D liquid to 6, and continue stirring for 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com