Self-elevating and self-propulsion type platform pile leg construction process

A self-propelled and leg technology, which is applied in the field of leg construction of self-elevating self-propelled platforms, can solve the problems of lack of rack plate assembly and welding process steps, poor support and stability of legs, welding deformation welds, etc. , to achieve the effect of ensuring the overall welding quality, reducing construction costs, and evenly heating the welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

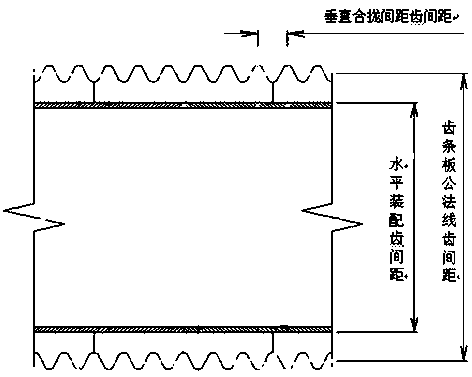

[0042] The self-elevating and self-propelled platform pile leg construction process of the present invention, through the manufacture of barrel joint parts, lengthening of barrel joints, structural marking, structural assembly, rack plate assembly and welding, structural inspection, internal accessories installation, water gauge installation, The transshipment sandblasting process is realized in cooperation, and the specific steps are as follows:

[0043] 1. Manufacture of cylinder section parts:

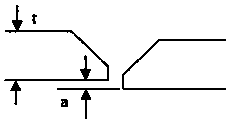

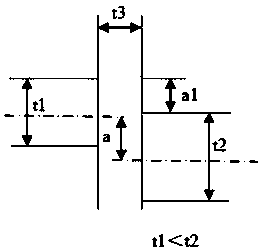

[0044]The first step, CNC blanking: cut and blank the material according to the CNC blanking diagram, check the size of the part after blanking, and indicate the plate thickness, material, part number, groove, groove type, and processing information on the part, among which the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com