Method for producing environmentally-friendly lightweight composite board

A lightweight, composite board technology, used in the processing of decorative materials and energy-saving building materials, can solve problems such as human health hazards and cancer, achieve zero formaldehyde environmental protection level, reduce the degree of human injury, and the effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

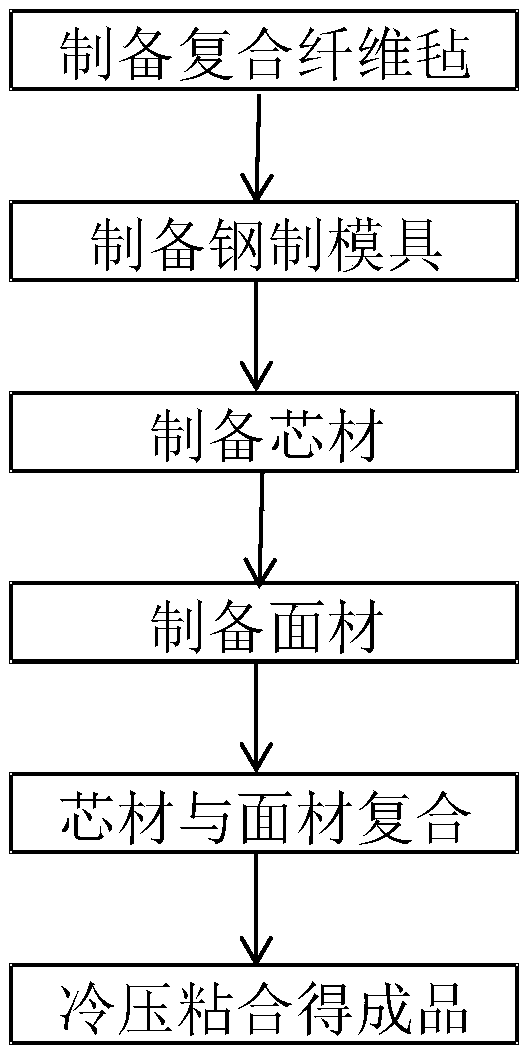

[0044] A method for preparing an environment-friendly lightweight composite board, comprising the following steps:

[0045](1) The natural fibers and polypropylene synthetic fibers are respectively removed from the impurities through the opening machine, and the vibrating cotton feeder outputs a uniform fiber cotton layer, and then the fiber cotton layer is processed into a thin mesh fiber layer by a carding machine, and then laid The mesh machine divides the mesh fiber thin layer into multiple layers to obtain a combined felt. Finally, the combined felt is needled by a needle punching machine to achieve compactness and uniform thickness, and then the needled combined felt is cut according to the target specification by an edge trimmer. , to obtain the natural fiber combined felt and the polypropylene synthetic fiber combined felt respectively, and the natural fiber combined felt and the polypropylene synthetic fiber combined felt are layered and superimposed to obtain the requ...

Embodiment 2

[0054] A method for preparing an environment-friendly lightweight composite board, comprising the following steps:

[0055] (1) The natural fibers and polypropylene synthetic fibers are respectively removed from the impurities through the opening machine, and the vibrating cotton feeder outputs a uniform fiber cotton layer, and then the fiber cotton layer is processed into a thin mesh fiber layer by a carding machine, and then laid The mesh machine divides the mesh fiber thin layer into multiple layers to obtain a combined felt. Finally, the combined felt is needled by a needle punching machine to achieve compactness and uniform thickness, and then the needled combined felt is cut according to the target specification by an edge trimmer. , to obtain the natural fiber combined felt and the polypropylene synthetic fiber combined felt respectively, and the natural fiber combined felt and the polypropylene synthetic fiber combined felt are layered and superimposed to obtain the req...

Embodiment 3

[0064] A method for preparing an environment-friendly lightweight composite board, comprising the following steps:

[0065] (1) The natural fibers and polypropylene synthetic fibers are respectively removed from the impurities through the opening machine, and the vibrating cotton feeder outputs a uniform fiber cotton layer, and then the fiber cotton layer is processed into a thin mesh fiber layer by a carding machine, and then laid The mesh machine divides the mesh fiber thin layer into multiple layers to obtain a combined felt. Finally, the combined felt is needled by a needle punching machine to achieve compactness and uniform thickness, and then the needled combined felt is cut according to the target specification by an edge trimmer. , to obtain the natural fiber combined felt and the polypropylene synthetic fiber combined felt respectively, and the natural fiber combined felt and the polypropylene synthetic fiber combined felt are layered and superimposed to obtain the req...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com