A method of crystallizing concentrated copper electrolysis waste liquid to produce crude nickel sulfate

A technology of copper electrolysis and nickel sulfate, applied in nickel sulfate, solution crystallization, separation methods, etc., can solve the problems of high labor intensity, harsh operating environment, low heat transfer efficiency, etc. Enhanced flow rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

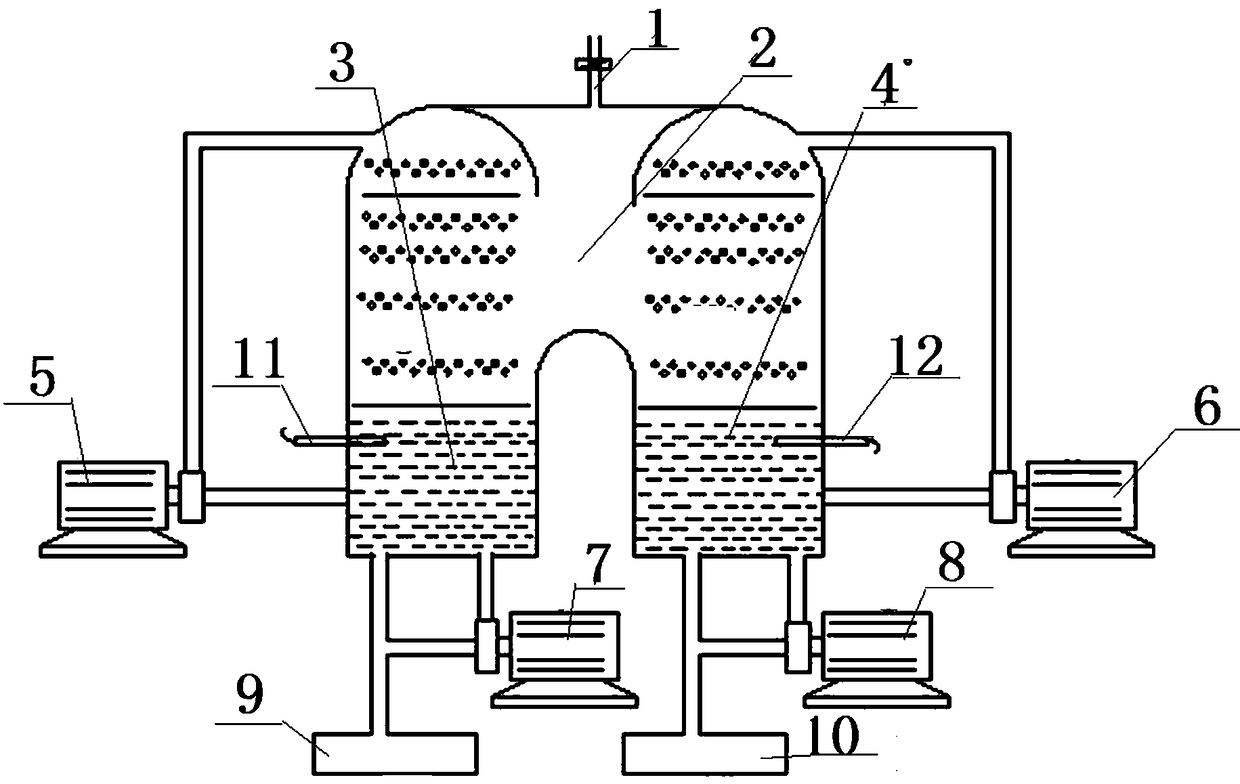

Image

Examples

Embodiment 1

[0025] Pass the 10m3 copper electrolytic waste liquid containing 0.3g / l of copper, 280g / l of acid, and 35g / l of nickel into such as figure 1 In the area to be evaporated as shown, the absorbent uses 10m3 of 98% concentrated sulfuric acid, and the vacuum degree reaches -70kPa under normal temperature conditions. Start the respective circulation pumps and spray circulation pumps to keep the space vacuum constant for 4 hours. Finally, when the volume of the solution in the evaporating liquid area is reduced to 3 m3, and the volume of the absorbent reaches 17 m3, the two circulation pumps corresponding to each container are stopped, and the 3 m3 evaporated liquid is filtered to obtain an acid-containing 930g / l, nickel-containing 2.1 m3 of 3g / l acid solution, 1.5 tons of crude nickel sulfate crystals. The concentration of concentrated sulfuric acid is reduced to 75% after absorbing water, and it is used in production as a production reagent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com