High flexural super sulfate cement and preparation method thereof

A super-sulfate cement with high flexural resistance technology, applied in cement production, sustainable waste treatment, solid waste management, etc., can solve the problems of easy sanding, low early strength, slow cement hydration and hardening speed, etc., and achieve a solution Easy to sand, improve early strength and later strength, solve the effect of low early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

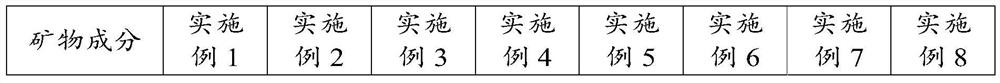

Examples

preparation example Construction

[0063] A second aspect of the present invention provides a method for preparing the above-mentioned granulated blast furnace slag activator, comprising the steps of: mixing granulated blast furnace slag, gypsum and high belite sulfoaluminate cement clinker and optionally mineral The excitation component is ground together with the optional coagulation-accelerating-strengthening component to obtain the high flexural super sulfate cement;

[0064] Alternatively, the gypsum and high belite sulphoaluminate cement clinker and optionally mineral stimulating components are co-ground with optional setting and strengthening components, and then with ground granulated blast furnace slag Mix to get.

[0065] As a preferred embodiment of the present invention, the preparation method of the above-mentioned granulated blast furnace slag activator comprises the following steps: combining granulated blast furnace slag, gypsum and high belite sulphoaluminate cement clinker and optionally miner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com