Plastic composition resistant to methanol fuel and gasoline and preparation method of composition

A composition and methanol-resistant technology, which is applied in the field of vehicle material composition and production, can solve problems such as inability to use oil pipelines, small methanol market scale, and insufficient methanol resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

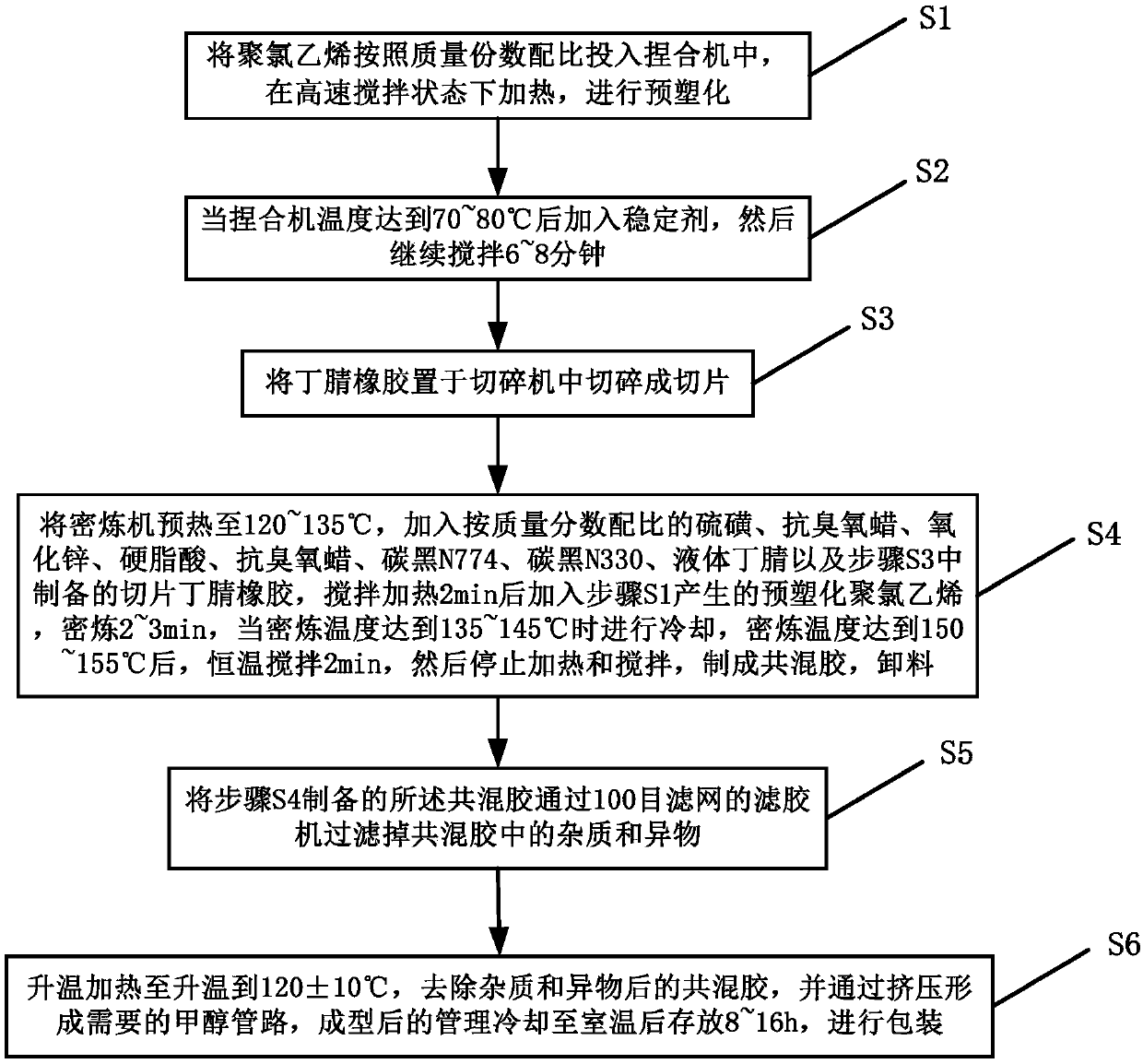

[0036] figure 1 It is a flow chart of the preparation method of a plastic composition resistant to methanol fuel and gasoline according to the present invention. like figure 1 As shown, the present invention also provides a preparation method applied to the plastic composition, comprising the steps of:

[0037] S1, put the polyvinyl chloride into the kneader according to the ratio of parts by weight, heat under high-speed stirring state, and perform pre-plasticization;

[0038] S2, when the temperature of the kneader reaches 70-80°C, add a stabilizer, and then continue to stir for 6-8 minutes;

[0039] S3, the nitrile rubber is placed in a shredder and chopped into slices;

[0040] S4, preheat the internal mixer to 120-135°C, add sulfur, anti-ozone wax, zinc oxide, stearic acid, anti-ozone wax, carbon black N774 (N774), carbon black N330 (N330 ), liquid nitrile and the sliced nitrile rubber prepared in step S3, add the pre-plasticized polyvinyl chloride produced in step ...

Embodiment 1

[0045] As shown in Table 1, formula No. 1 is a plastic composition resistant to methanol fuel and gasoline, including base rubber species, additives and anti-aging agents, wherein the components and parts by weight of the base rubber species are nitrile rubber 80 , PVC 40. The components and parts by weight of the additive are zinc oxide 6, stearic acid 1, sulfur 0.5 anti-ozone wax 1, di-sec-octyl phthalate (DCP) 0.5, carbon black N774 50, carbon black N330 30, Barium sulfate 20, liquid nitrile 5, accelerator CZ 2, accelerator TMTD 1.5, antioxidant RD 2, antioxidant MB 1.

Embodiment 2

[0047]As shown in Table 1, formula No. 2 is a plastic composition resistant to methanol fuel and gasoline, including base rubber species, additives and antioxidants, wherein the components and parts by weight of the base rubber species are nitrile rubber 50 , PVC 40. The components and parts by weight of the additive are zinc oxide 3, stearic acid 1, sulfur 0.5 anti-ozone wax 2, di-sec-octyl phthalate (DCP) 0.5, carbon black N774 30, carbon black N330 25, Barium sulfate 20, liquid nitrile 7, accelerator CZ 3.5, accelerator TMTD 2, antioxidant RD 3, antioxidant MB 3.

[0048] Table 1

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com