an enhanced co 2 Oil displacement additives that are miscible with crude oil and reduce the viscosity of crude oil

An oil-soluble viscosity reducer and additive technology, applied in the field of oil displacement additives, can solve the problems of high MMP, unattainable, low displacement efficiency, etc., and achieve the effects of enhancing fluidity, good injectability, and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

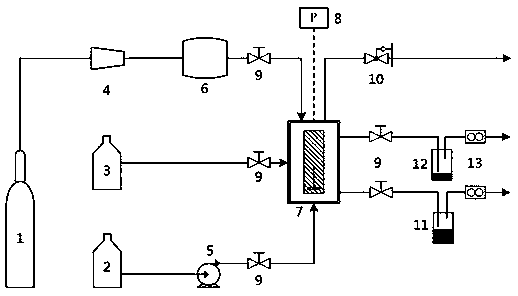

Method used

Image

Examples

Embodiment 1

[0019] Example 1 Preparation of oil displacement additive and determination of its viscosity-reducing performance on crude oil

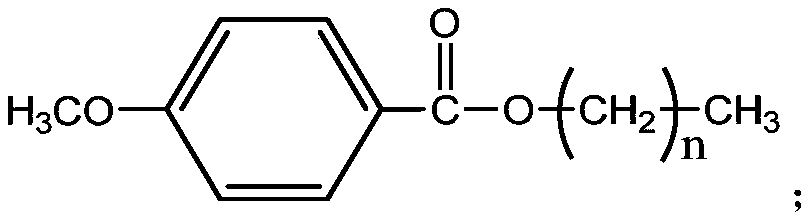

[0020] The oil displacement additive is composed of a solubilizer propyl toluate and a viscosity reducer stearyl acrylate-vinyl acetate-acrylamide copolymer, and the weight ratio of the solubilizer to the viscosity reducer is 4:1. Add the solubilizer and the viscosity reducer into the beaker, stir at room temperature for more than 1 hour to mix well, and let stand to obtain the oil displacement additive.

[0021] The preparation method of the stearyl acrylate-vinyl acetate-acrylamide copolymer is as follows: in a 150ml three-necked flask equipped with a condenser, a thermometer and a mechanical stirring device, add 80ml of toluene as a reaction solvent, and then add a total amount of 10g , octadecyl acrylate, vinyl acetate and acrylamide in a molar ratio of 2:3:5, and the initiator azobisisobutyronitrile of 5% of the total weight of raw materials, th...

Embodiment 2

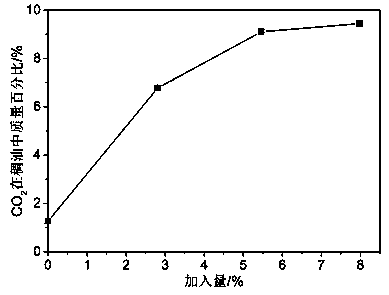

[0028] Embodiment 2 tests oil displacement additive to promote CO 2 Solubility in heavy oil

[0029] The oil displacement additive used is consistent with Example 1. The airtightness of the instrument needs to be checked before the experiment, and CO is introduced into the autoclave 2 , kept at 25MPa for 2h, if the pressure fluctuation does not exceed 1%, it can be considered that the airtightness is good. During the experiment, first weigh 25 g of heavy oil in the balance kettle, turn on the CO 2 Injection valve and gas phase sampling valve, with 100 ~ 200ml / min of CO 2 Air purging for 10 minutes, the air in the kettle was exhausted, and then all valves were closed. Turn on the constant temperature water bath, increase the pressure to 15MPa, stir and balance for more than 1 hour to achieve gas-liquid equilibrium. After that, slightly open the liquid phase sampling valve, take out about 20mg of liquid phase sample, and measure the amount of released gas. During the proces...

Embodiment 3

[0030] Embodiment 3 prepares oil displacement additive and measures its performance

[0031] The oil displacement additive is composed of a solubilizer propyl toluate and a viscosity reducer lauryl acrylate-vinyl acetate-acrylamide copolymer, and the weight ratio of the solubilizer to the viscosity reducer is 4:1. Add the solubilizer and the viscosity reducer into the beaker, stir at room temperature for more than 1 hour to mix well, and let stand to obtain the oil displacement additive.

[0032] The preparation method of described lauryl acrylate-vinyl acetate-acrylamide copolymer is: in the 150ml three-necked flask that condenser, thermometer and mechanical stirring device are housed, add 80ml toluene as reaction solvent, then add total amount 10g , lauryl acrylate, vinyl acetate and acrylamide in a molar ratio of 2:3:5, and the initiator azobisisobutyronitrile of 5% of the total weight of raw materials, through N 2 After displacing the air in the reaction bottle, stir and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com