Malt roasting technology for craft beer

A roasting and malting technology, which is applied in the field of craft beer malt roasting technology, can solve the problems of inability to achieve uniform heating of materials, inability to meet the needs of process production, inability to achieve uniform mixing of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

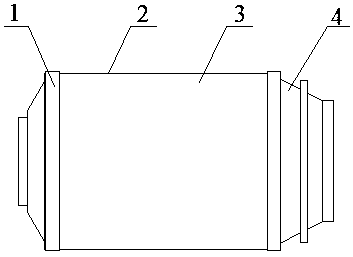

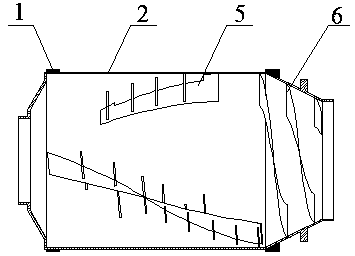

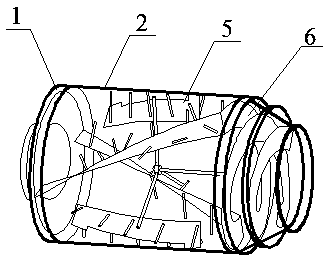

[0063] 1.1 A malt roasting drum

[0064] as attached figure 2 , 3 As shown, in a malt roasting drum of the present invention, a stirring blade is arranged on the inner wall of the roasting drum 2, and the stirring blade is divided into a long blade 6 and a short blade 5, and the long blade 6 and the short blade 5 rotate in the opposite direction, and It is distributed alternately, wherein the long blades 6 are arranged throughout the length of the roasting drum 2, and the short blades 5 are located in the middle of the inner wall of the roasting drum 2, and their roots are not completely connected with the inner wall of the roasting drum 2. [Design intent: The long blade 6 and the short blade 5 rotate in the opposite direction. When feeding in the forward direction, the long blade 6 and the short blade 5 are turned forward and reversed, so that the material is evenly stirred in the roasting drum 2; the long blade 6 and the short blade The blades 5 are distributed alternatel...

Embodiment 2

[0091] 2.1 A malt roasting furnace for craft beer

[0092] as attached Figure 14 , 15 , 16, 17, and 18, a kind of craft beer malt roasting furnace of the present invention includes: the roasting drum 2 of the cabinet 9, the cabinet 9, and the machine for supporting the roasting drum 2 Rack 10. The material door 12 at one end of the roasting drum 2 is provided with a feed bin 8 , and the roasting drum 2 is connected and driven with the external drive assembly 7 via a horizontally arranged rotating shaft 17 . One end of the rotating shaft 17 is supported by the bearing 14 on the frame 10, and the other end is supported by the supporting wheel 27. The external drive assembly 7 includes a motor and a reducer at the output end of the motor.

[0093] combined with Figure 21 , optimized design for the roasting drum 2 and the material heating method, firstly, a closed hot air chamber 36 is set outside the roasting drum 2, and the hot air in the hot air chamber 36 is used to indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com