Acid stress resistant component and application thereof

A technology of amino acids and lactic acid bacteria, applied in the field of bioengineering, can solve problems such as heavy workload, low success rate, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

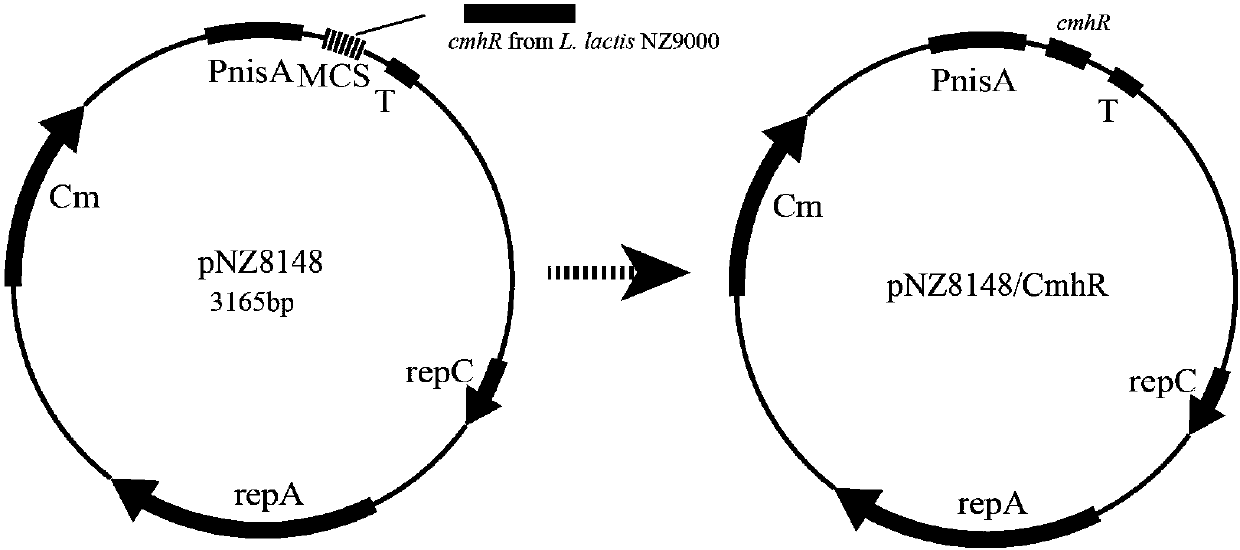

[0024] Construction of embodiment 1 recombinant strain

[0025] The gene sequence of cmhR as shown in SEQ ID NO.2 was obtained from L.lactis NZ9000 in the NCBI database, and cloned into the expression plasmid pNZ8148 of Lactococcus lactis to obtain the recombinant plasmid pNZ8148 / CmhR, which was then electroporated into In the host strain L. lactis NZ9000, a recombinant strain L. lactis NZ9000 (pNZ8148 / CmhR) was obtained.

[0026] details as follows:

[0027] According to the gene sequence of cmhR, primers cmhR-F and cmhR-R (Table 1) as shown in SEQ ID NO.3 and SEQ ID NO.4 were designed respectively, and the genome of L.lactis NZ9000 was used as template PCR amplification to obtain SEQ ID NO. The gene fragment shown in ID NO.2. The PCR product and the vector pNZ8148 were double digested with NcoI and XbaI respectively, and the digested products were purified and ligated. The ligation product was transformed into Escherichia coli MC1061 (commercial strain) competent, positiv...

Embodiment 2

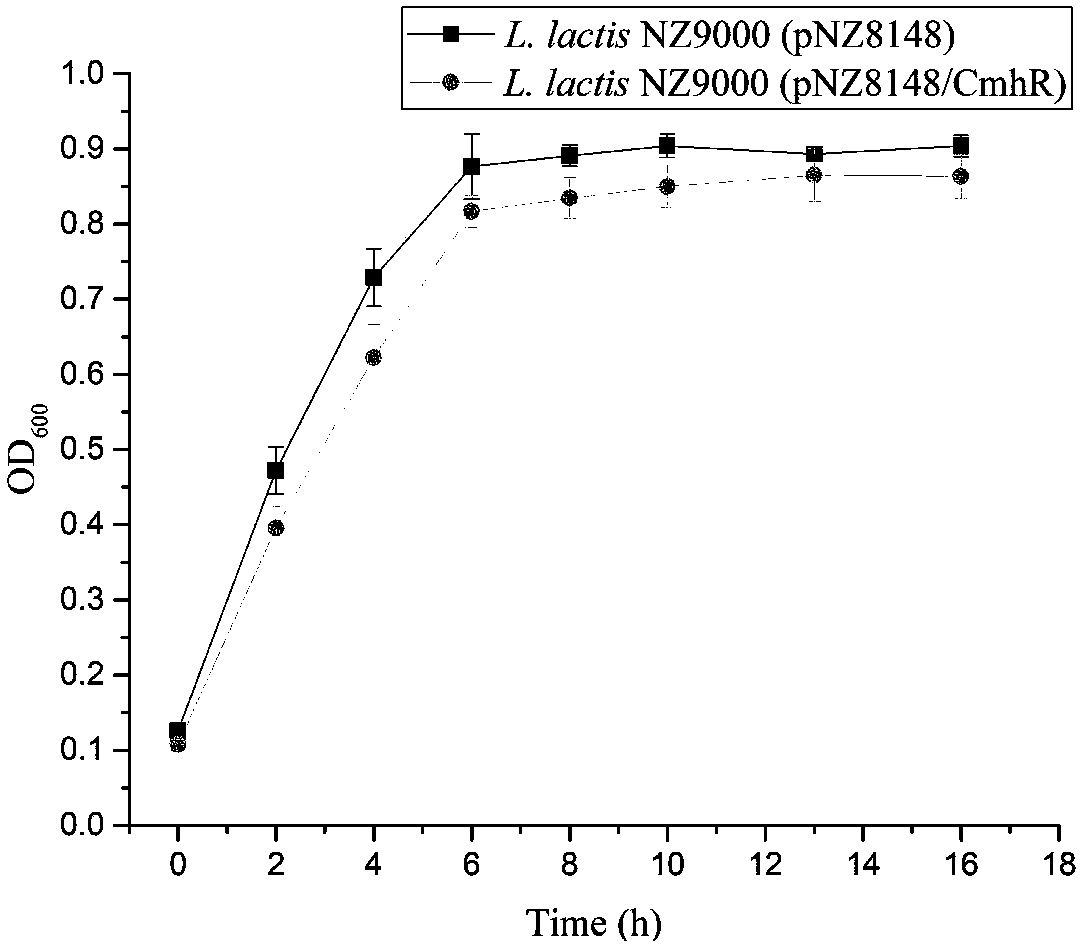

[0031] The growth performance test of embodiment 2 overexpression CmhR bacterial strain

[0032] To investigate the growth of bacterial strains when CmhR was overexpressed, the bacterial strains L.lactis NZ9000 (pNZ8148 / CmhR) and L.lactisNZ9000 (pNZ8148) (control) were inoculated in GM17 liquid medium (1 mL ), and placed in a 30°C incubator for overnight culture. The seed solution was then transferred to fresh chloramphenicol (10 μg / mL) GM17 liquid medium with a 2% inoculation amount, and cultured statically at 30°C. Samples were taken every 2 hours, and the OD value at a wavelength of 600nm was measured. Grow to OD 600 At 0.4, 10ng / mL nisin was added to induce the expression of CmhR protein. Taking time as the abscissa, OD 600 The value is the vertical axis, and the growth curve is drawn.

[0033] The result is as figure 2 shown. The growth performance test analysis showed that the biomass of the recombinant strain was not significantly different from that of the cont...

Embodiment 3

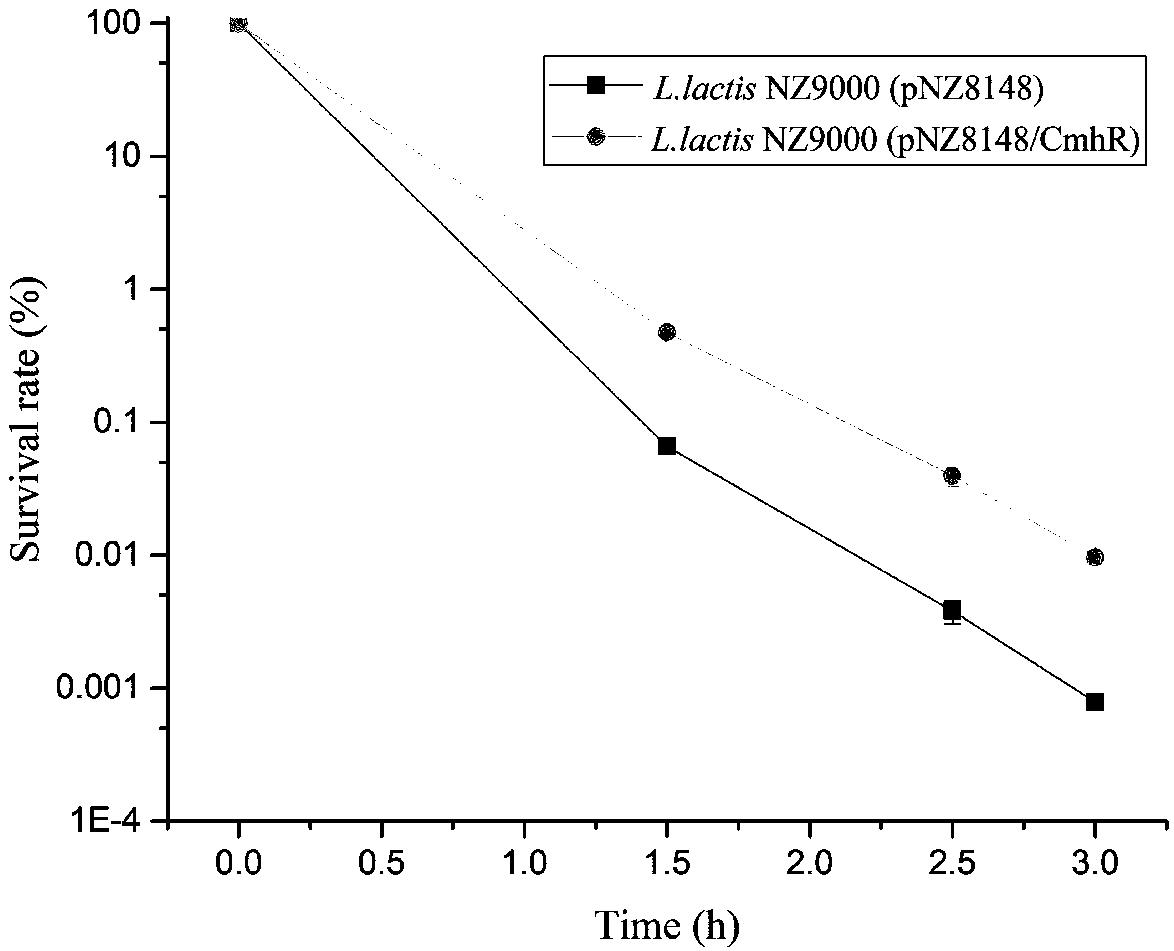

[0034] Tolerance test under the acid stress condition of embodiment 3

[0035] For the analysis of the tolerance of the investigated strains to acid, the survival rates of the recombinant strains and the control strains at pH 4.0 were measured.

[0036] The specific operation method is as follows: the strain was induced and cultured for 6 hours, the cells were collected by centrifugation, washed twice with 0.85% normal saline, and then resuspended in an equal volume of fresh GM17 (containing 10 μg / mL chloramphenicol) at pH 4.0 (adjusted by lactic acid). , coercion at different times. After the stress, the bacterial suspension was washed twice and then resuspended in an equal volume of normal saline. 10 μL of the resuspension was taken, diluted with different gradients, and planted on a GM17 chloramphenicol plate to determine the number of viable bacteria and the survival rate.

[0037] According to the analysis of the tolerance test, the survival rate of the recombinant strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com