Full-automatic corrugated pipe tempering furnace

A bellows and tempering furnace technology, applied in the field of bellows, can solve the problems of reducing the elastic characteristics of bellows, low production efficiency, increasing cracks in bellows, etc., to reduce the generation of cracks, shorten time and labor, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

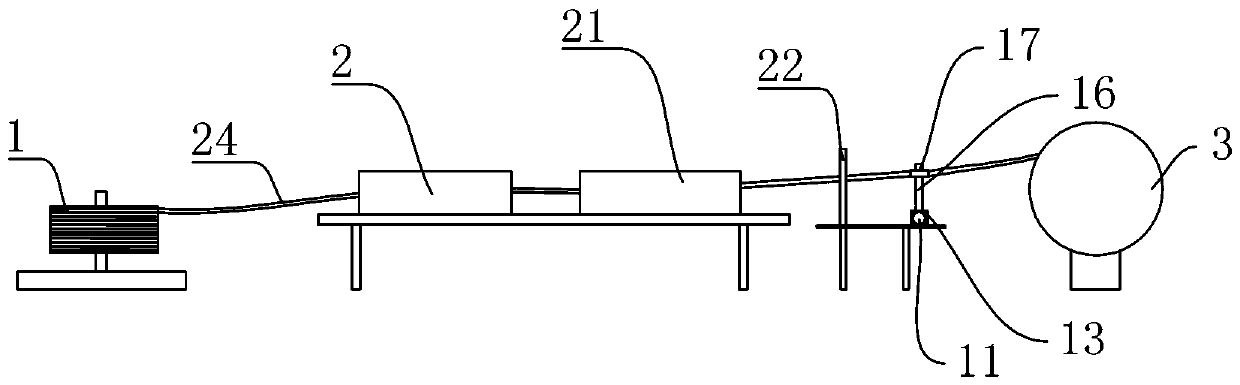

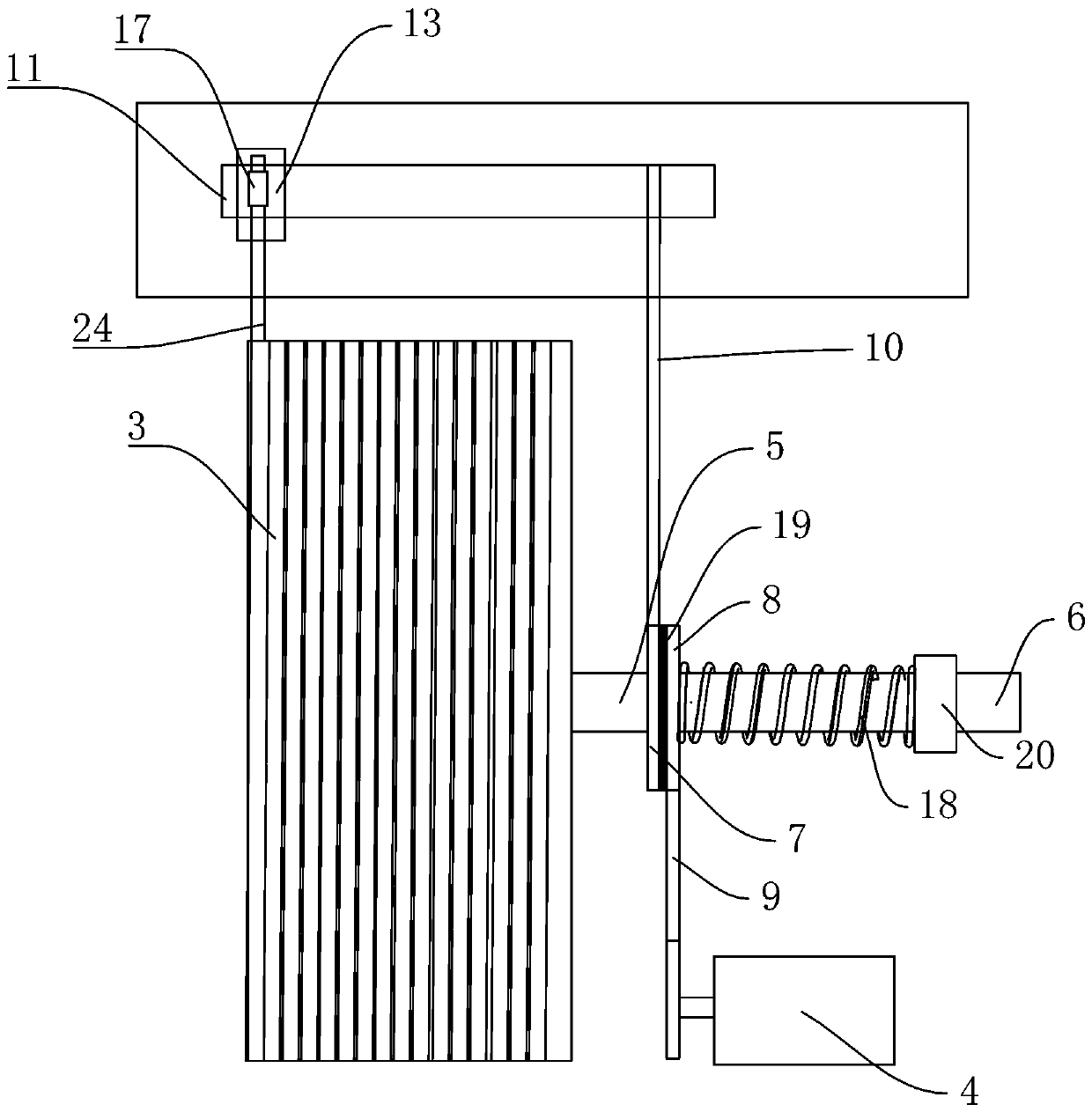

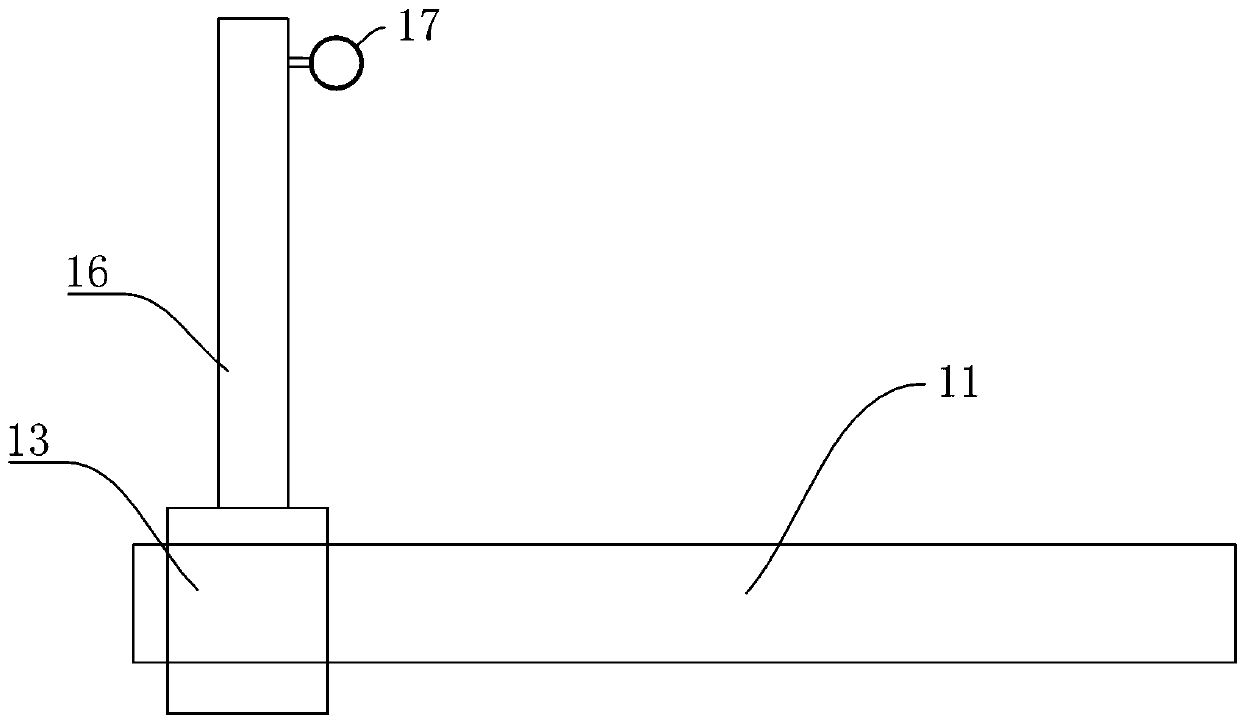

[0022] The present invention is further explained in conjunction with the accompanying drawings.

[0023] see Figure 1 to Figure 5 A bellows fully automatic tempering furnace is shown, including a discharge device, a tempering device, a material collection device and a drive motor 4, the discharge device includes a plurality of discharge turntables 1, the discharge turntables 1 are placed horizontally, and the discharge turntables 1 is provided with a bearing in the middle, so as to rotate the discharge turntable 1. One end of the bellows 24 is wound on the discharge turntable 1, the tempering device includes a tempering furnace 2 and a frame, the tempering furnace 2 is arranged on the frame, a hearth is arranged in the tempering furnace 2, and the collecting device includes a plurality of discharge The collecting turntable 3 matched with the turntable 1, the other end of the bellows 24 passes through the hearth of the tempering furnace 2 and is wound on the collecting turnt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com