A high-power cylindrical lithium-ion battery cell

A cylindrical, lithium-ion technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of high power and low self-consumption, battery charging lithium, and battery internal resistance, etc., to reduce the edge The risk of broken tape, the effect of reducing impedance and improving the productivity of good products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

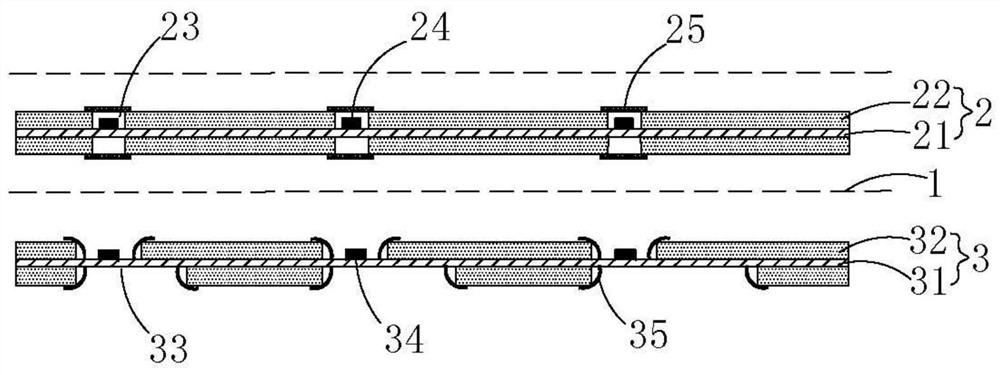

[0021] This embodiment is a high-power cylindrical lithium-ion cell, which is formed by stacking a positive electrode sheet 3, a separator 1 and a negative electrode sheet 2 sequentially and then winding them in the same direction. The negative electrode sheet 2 includes a negative electrode current collector 21 and is coated on The negative electrode active material layer 22 on both sides of the negative electrode current collector 21, the two sides of the negative electrode current collector 21 are respectively reserved with three negative electrode gaps 23 that are not coated with the negative electrode active material layer 22, and the three negative electrode gaps 23 are respectively arranged on the negative electrode sheet 2, and the widths of the three negative gaps 23 are kept equal; the three negative gaps 23 are respectively welded with negative tabs 24, and the three negative tabs 24 are welded on the same side of the negative sheet 2, The negative electrode gap 23 i...

Embodiment 2

[0024] This embodiment is a high-power cylindrical lithium-ion cell, which is formed by stacking a positive electrode sheet 3, a separator 1 and a negative electrode sheet 2 sequentially and then winding them in the same direction. The negative electrode sheet 2 includes a negative electrode current collector 21 and is coated on The negative electrode active material layer 22 on both sides of the negative electrode current collector 21, the two sides of the negative electrode current collector 21 are respectively reserved with four negative electrode gaps 23 that are not coated with the negative electrode active material layer 22, and the four negative electrode gaps 23 are respectively arranged on the negative electrode. The head, middle and tail of the sheet 2, and the widths of the four negative gaps 23 are kept equal; the four negative gaps 23 are respectively welded with negative tabs 24, and the four negative tabs 24 are welded on the same side of the negative sheet 2 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com