Nanometer far infrared carbon-fiber heating sheet

A far-infrared carbon fiber, heating sheet technology, applied in electric heating devices, ohmic resistance heating, ohmic resistance heating parts and other directions, can solve the problems of hidden safety hazards, no waterproof function, many materials and equipment, etc., to improve the service life and use The effect of safety, improving safety and comfort, and avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

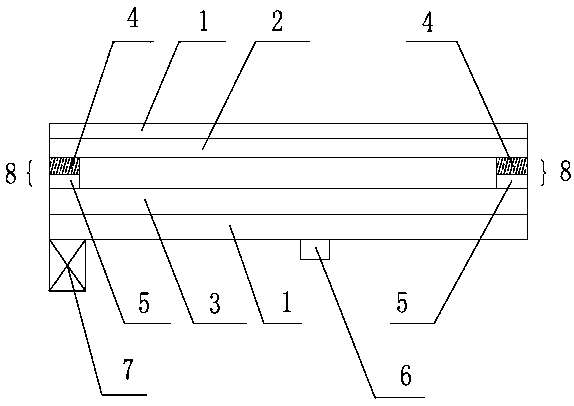

[0027] Embodiment 1, refer to attached figure 1 with figure 2 :

[0028] A nano far-infrared carbon fiber heating sheet, comprising a flexible base material layer 1, a waterproof layer 2, a far-infrared heating layer 3 and a flexible base material layer 1 attached in sequence, the far-infrared heating layer 3 includes carbon fibers arranged in a mesh, and the mesh-like The opposite ends of the arranged carbon fibers are covered and connected with conductive cloth 8, the conductive cloth includes a conductive substrate layer 4 and a conductive adhesive layer 5, and the two conductive cloths are connected to the power connector through positive and negative wires.

[0029] The carbon fibers arranged in a mesh form are overlapped with each other, and the overlapped structure is fixed by sutures. The sutures are conductive threads, and the conductive threads are specifically polyester threads containing silver-plated conductive fibers.

[0030] The nano far-infrared carbon fibe...

Embodiment 2

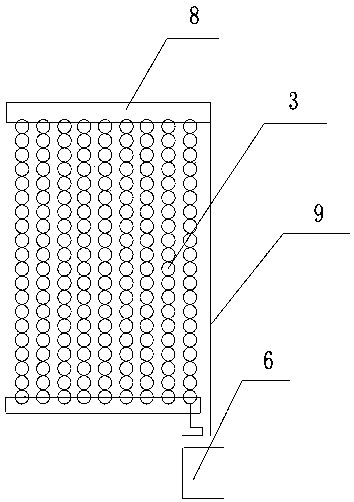

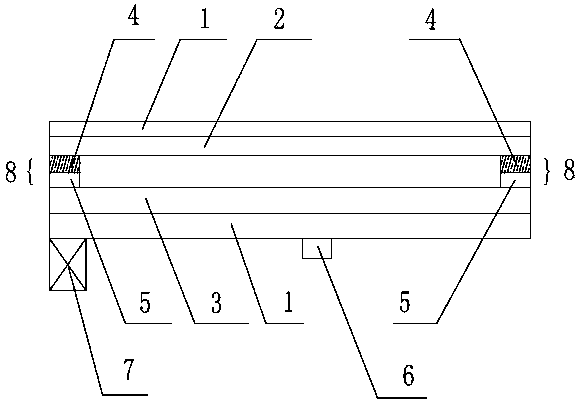

[0036] Embodiment 2, refer to attached figure 2 with image 3 :

[0037] A nanometer far-infrared carbon fiber heating sheet, comprising a waterproof layer 2, a flexible base material layer 1, a far-infrared heating layer 3 and a flexible base material layer 1 attached in sequence, the far-infrared heating layer 3 includes carbon fibers arranged in a net shape, and the net shape The opposite ends of the arranged carbon fibers are covered and connected with conductive cloth 8, the conductive cloth includes a conductive substrate layer 4 and a conductive adhesive layer 5, and the two conductive cloths are connected to the power connector through positive and negative wires.

[0038] The carbon fibers arranged in a net shape are overlapping structures, and the overlapping structures are fixed by sutures, the sutures are conductive threads, and the conductive threads are specifically nano-carbon fiber threads.

[0039] The nano far-infrared carbon fiber heating sheet also inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com