Environmentally friendly and low-cost industrial zirconium carbonate production method

An environment-friendly, zirconium carbonate technology, applied in chemical instruments and methods, zirconium compounds, inorganic chemistry, etc., can solve the problems of unrecycled, increased load of water treatment section, waste of resources, etc., and achieve the effect of washing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

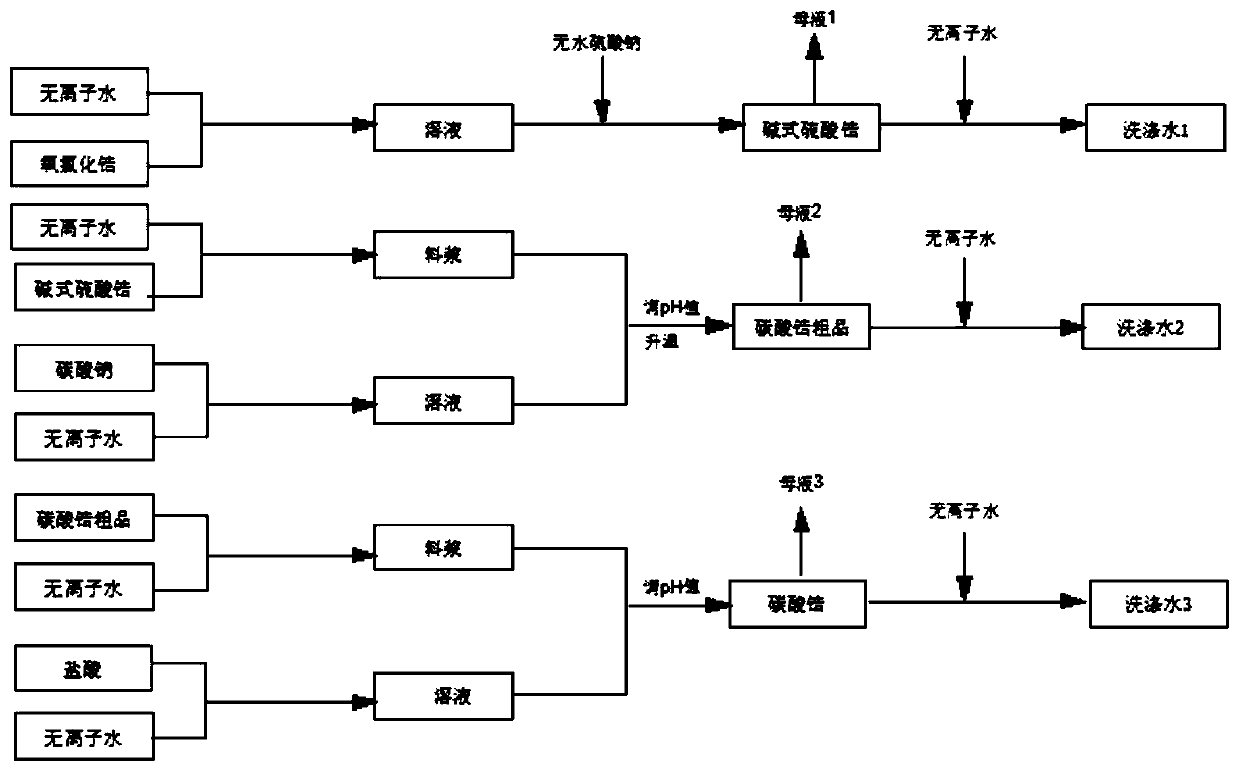

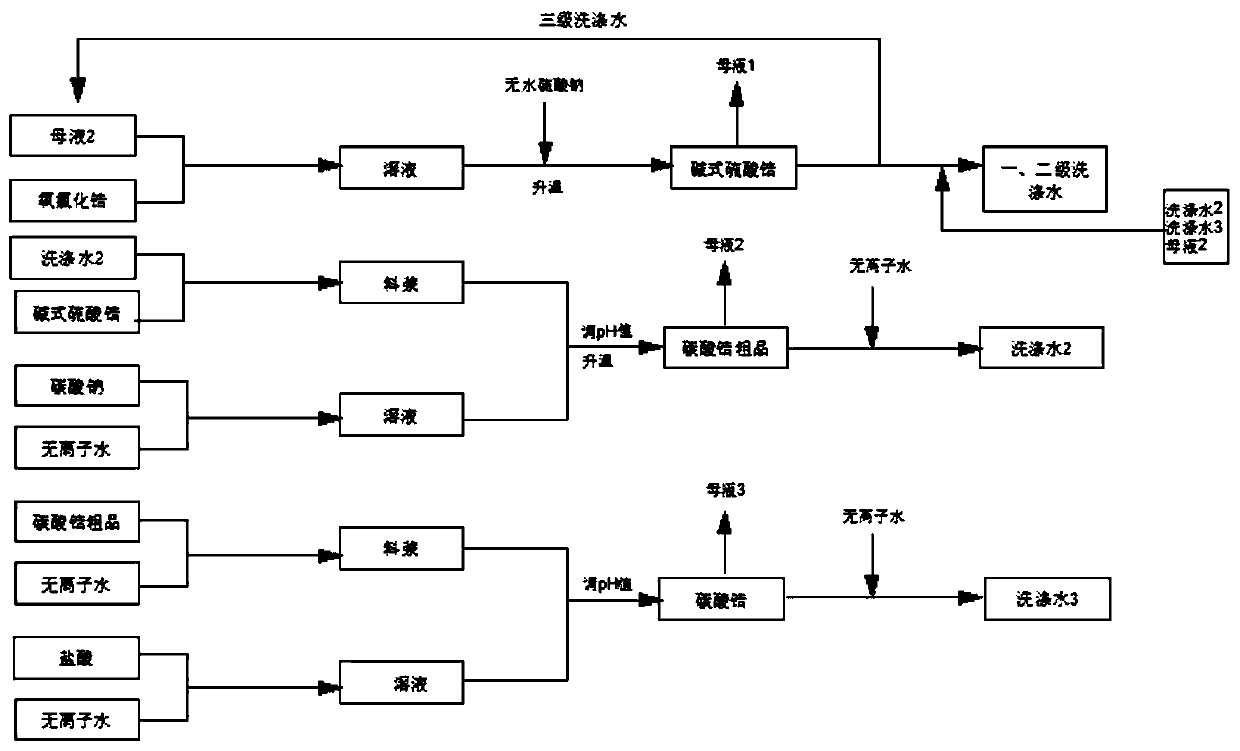

[0052] A kind of production method of environment-friendly and low-cost industrial zirconium carbonate of the present invention

[0053] The waste water from the crude zirconium carbonate workshop and the product zirconium carbonate workshop is used in the basic zirconium sulfate workshop to replace deionized water, and is used as basic zirconium sulfate washing water and raw material preparation water, as well as raw material basic zirconium sulfate in the crude zirconium carbonate workshop. Slurry water, the specific operation steps are as follows:

[0054] ①. Basic zirconium sulfate intermediate first stage washing

[0055] The zirconium carbonate washing water discharged from the zirconium carbonate production section is collected entirely and used for the first-stage washing of the basic zirconium sulfate intermediate in the intermediate basic zirconium sulfate workshop section;

[0056] The mass ratio of the basic zirconium sulfate intermediate for the first-stage washi...

Embodiment 2

[0082] The waste water from the crude zirconium carbonate workshop and the product zirconium carbonate workshop is used in the basic zirconium sulfate workshop to replace deionized water, and is used as basic zirconium sulfate washing water and raw material preparation water, as well as raw material basic zirconium sulfate in the crude zirconium carbonate workshop. Slurry water, the specific operation steps are as follows:

[0083] ①. Basic zirconium sulfate intermediate first stage washing

[0084] The zirconium carbonate washing water discharged from the zirconium carbonate production section is collected entirely and used for the first-stage washing of the basic zirconium sulfate intermediate in the intermediate basic zirconium sulfate workshop section;

[0085] The mass ratio of the basic zirconium sulfate intermediate for the first-stage washing is: basic zirconium sulfate in terms of solids: zirconium carbonate washing water=200:500.

[0086] ②.Second stage washing of b...

Embodiment 3

[0111] The waste water from the crude zirconium carbonate workshop and the product zirconium carbonate workshop is used in the basic zirconium sulfate workshop to replace deionized water, and is used as basic zirconium sulfate washing water and raw material preparation water, as well as raw material basic zirconium sulfate in the crude zirconium carbonate workshop. Slurry water, the specific operation steps are as follows:

[0112] ①. Basic zirconium sulfate intermediate first stage washing

[0113] The zirconium carbonate washing water discharged from the zirconium carbonate production section is collected entirely and used for the first-stage washing of the basic zirconium sulfate intermediate in the intermediate basic zirconium sulfate workshop section;

[0114] The mass ratio of the basic zirconium sulfate intermediate for the first-stage washing is: basic zirconium sulfate in terms of solids: zirconium carbonate washing water=200:500.

[0115] ②.Second stage washing of b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com