Low-melting-point glass powder and preparation method thereof

A low-melting point glass and glass powder technology, which is applied in the preparation of the low-melting point glass powder, in the field of low-melting point glass powder, can solve the problem of narrow application range of lead-free bismuth salt glass powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

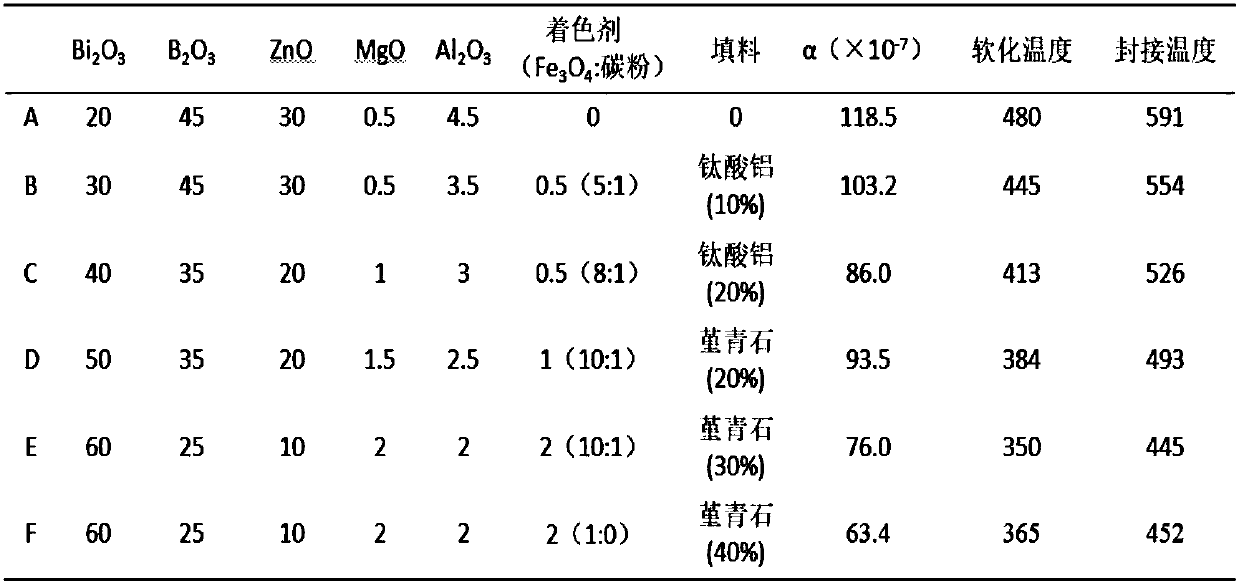

[0028] Weigh 20 parts of Bi according to the unit mass 2 o 3 , 30 parts of ZnO, 45 parts of B 2 o 3 , 0.5 parts of MgO, 4.5 parts of Al 2 o 3 , They were melted in a lifting furnace at 1100°C, cooled and ball-milled into primary glass powder, and then prepared into nano-glass powder by freezing and grinding. The particle size of the glass powder is 150nm to 450nm.

Embodiment 2

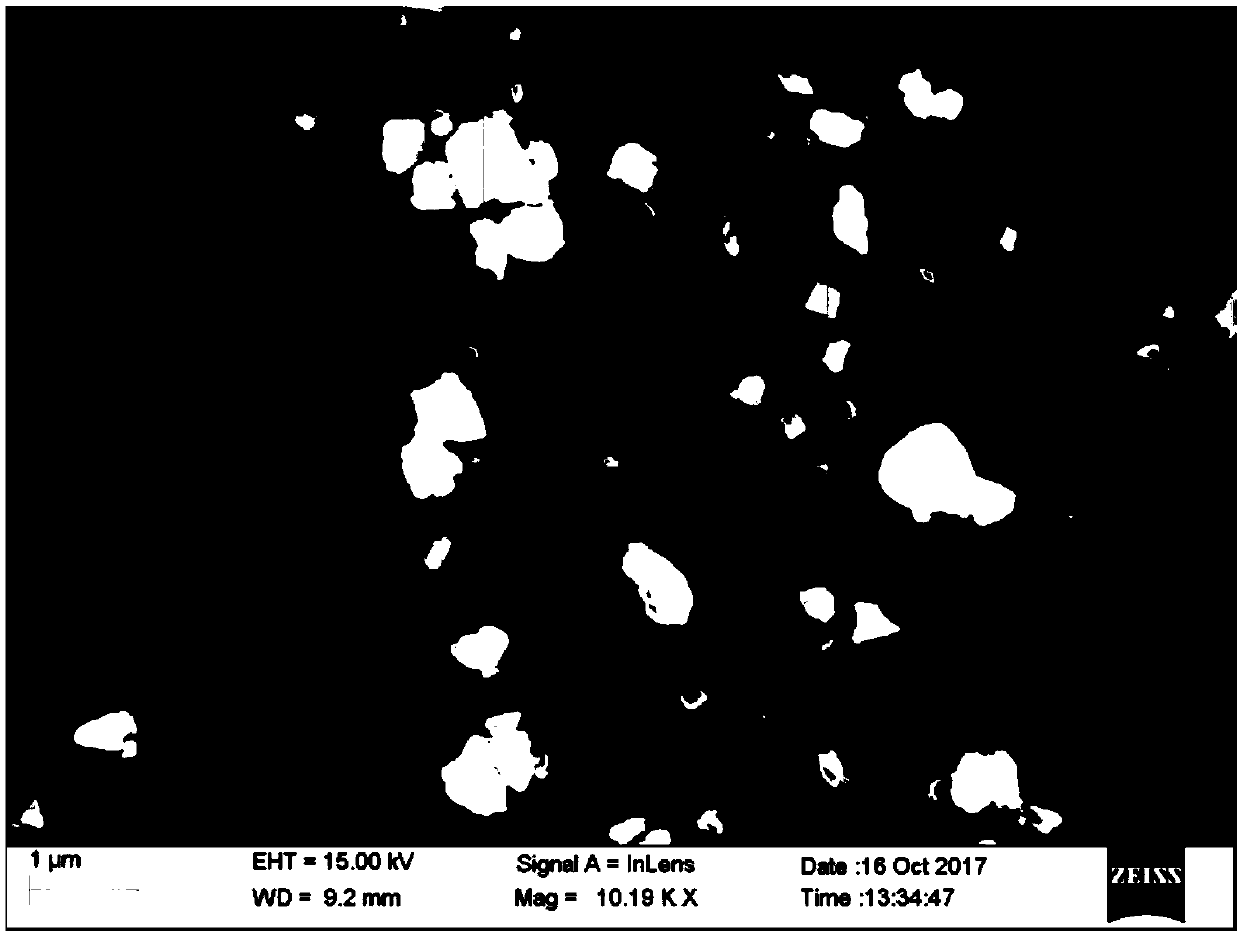

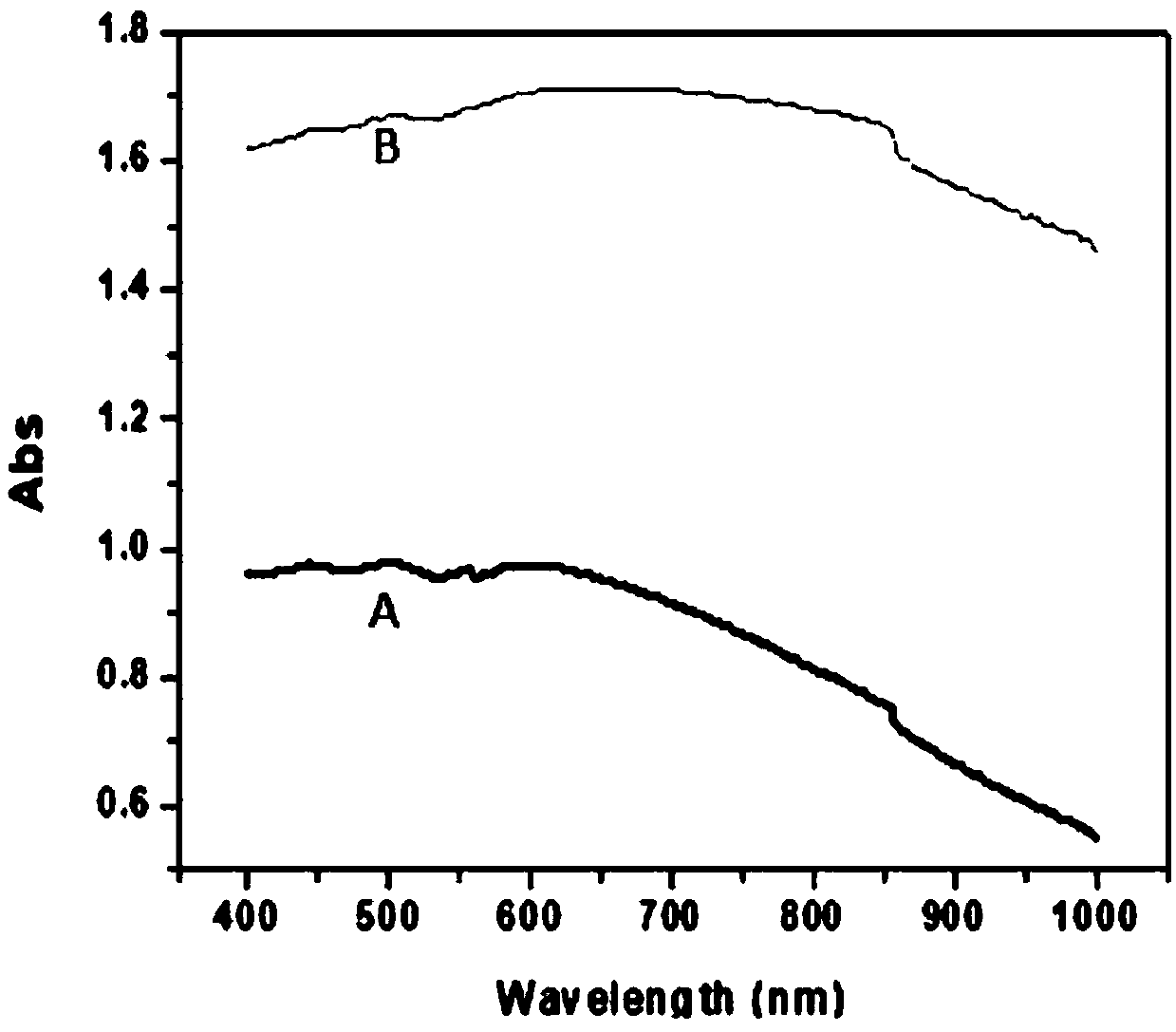

[0030] Weigh 30 parts of Bi according to the unit mass 2 o 3 , 30 parts of ZnO, 45 parts of B 2 o 3 , 0.5 parts of MgO, 3.5 parts of Al 2 o 3 , they were smelted in a lifting furnace at 1100°C, cooled and ball-milled into primary glass powder, and then 0.5 parts of colorant and aluminum titanate accounting for 10% of the total mass percentage of glass powder were added, wherein the colorant was Fe with a mass ratio of 5:1 3 o 4 / carbon powder mixture, and finally prepare nano glass powder by freezing and grinding, and the particle size of the glass powder is 150nm-450nm. figure 2 It is the particle size chart of the glass powder after freezing and grinding. image 3 It is a comparison chart of light absorption intensity between Example 1 and Example 2. Curve A corresponds to Example 1, and Curve B corresponds to Example 2. After adding a colorant, the light absorption ability is greatly improved.

Embodiment 3

[0032] Weigh 40 parts of Bi according to the unit mass 2 o 3 , 20 parts of ZnO, 35 parts of B 2 o 3 , 1 part of MgO, 3 parts of Al 2 o 3 , they were smelted in a lifting furnace at 1100°C, cooled and ball-milled into primary glass powder, and then 0.5 parts of colorant and aluminum titanate accounting for 20% of the total mass percentage of glass powder were added, wherein the colorant was Fe with a mass ratio of 8:1 3 o 4 / carbon powder mixture, and finally prepare nano glass powder by freezing and grinding, and the particle size of the glass powder is 50nm-150nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com