Fluidized-bed combustion device

A technology of combustion device and fluidized bed, which is applied in the direction of fluidized bed combustion equipment, burning fuel in molten state, combustion method, etc. It can solve the problems of short operation period and difficulty in slag discharge of garbage furnace, and achieve the improvement of fluidization condition, Good economic benefits, reducing the number of shutdowns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

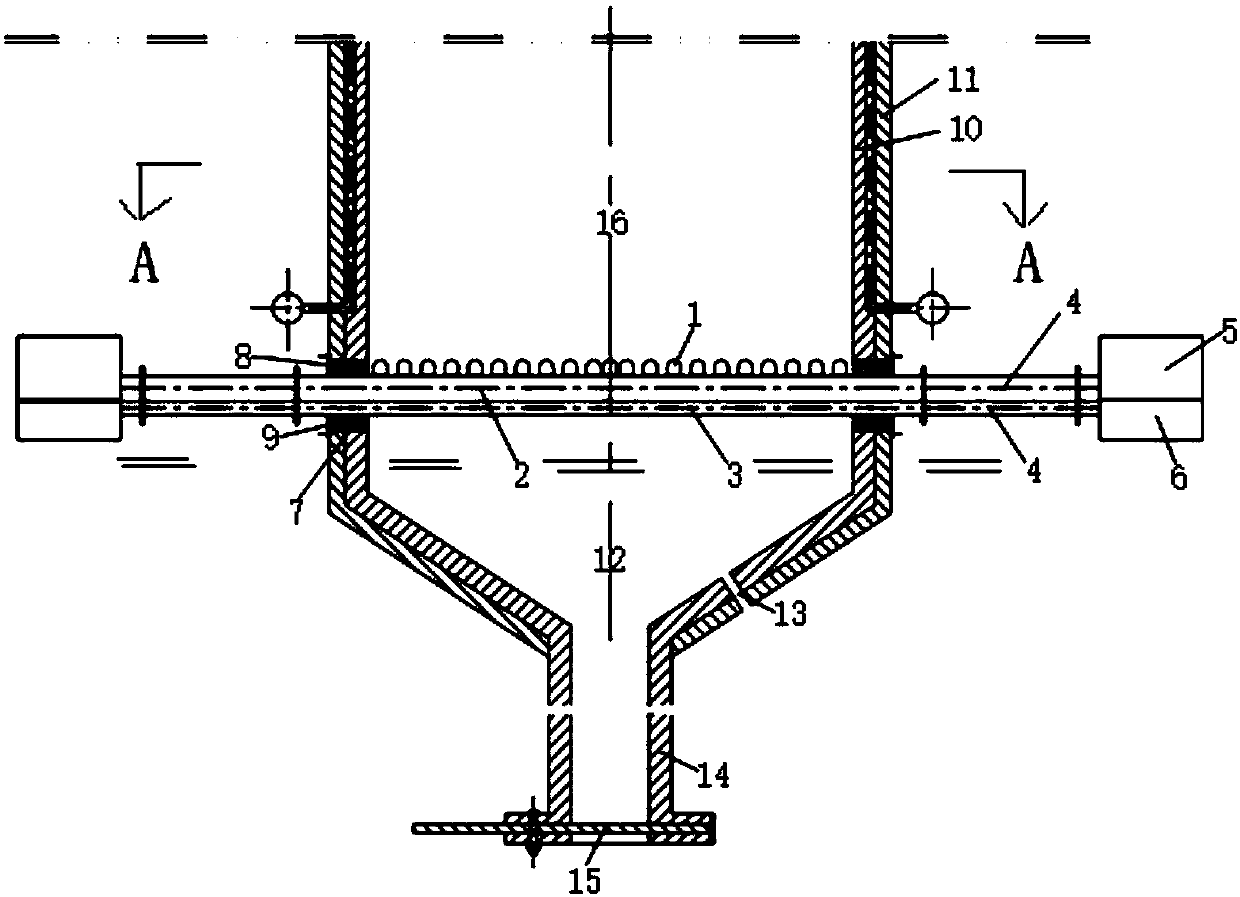

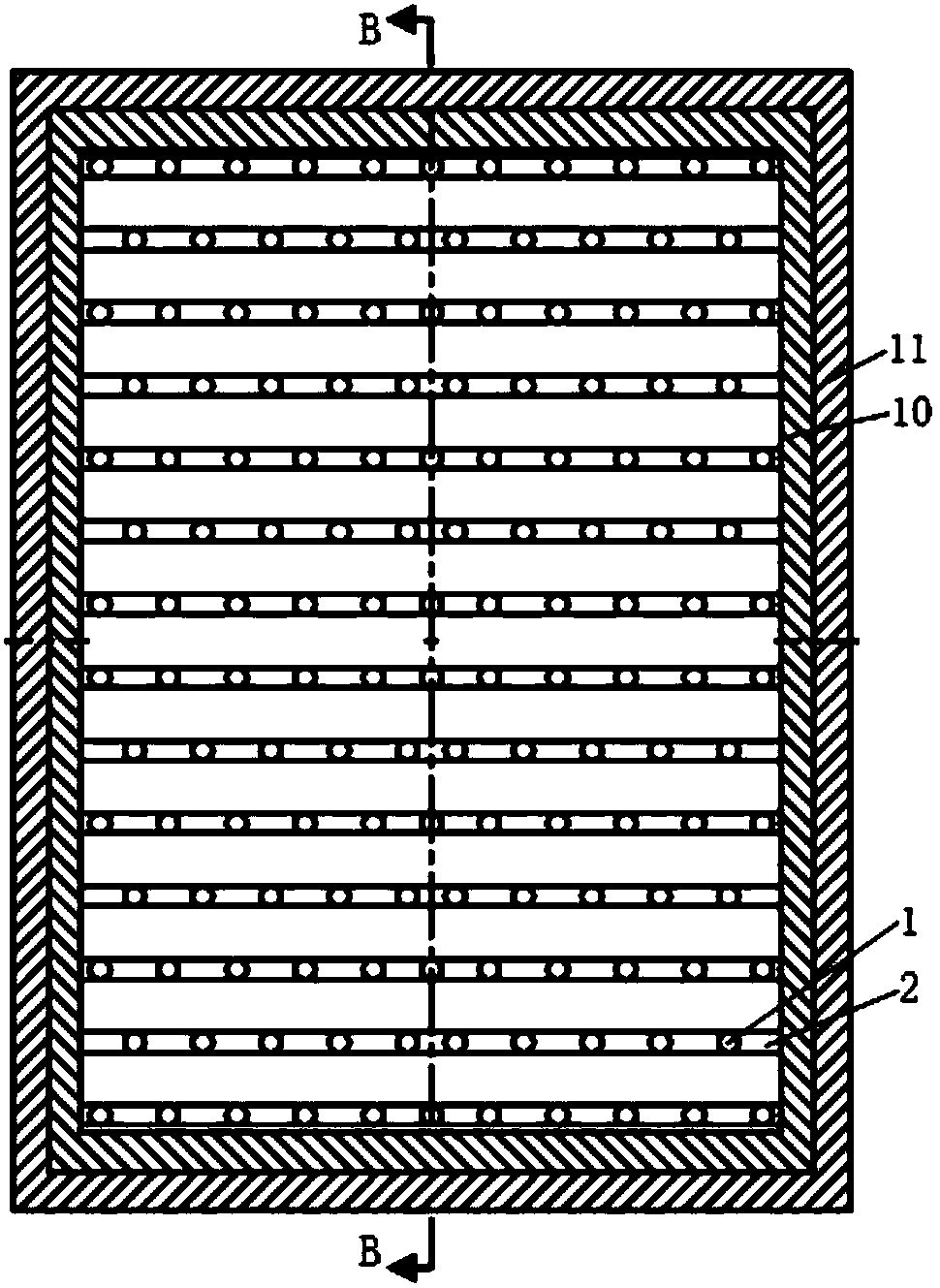

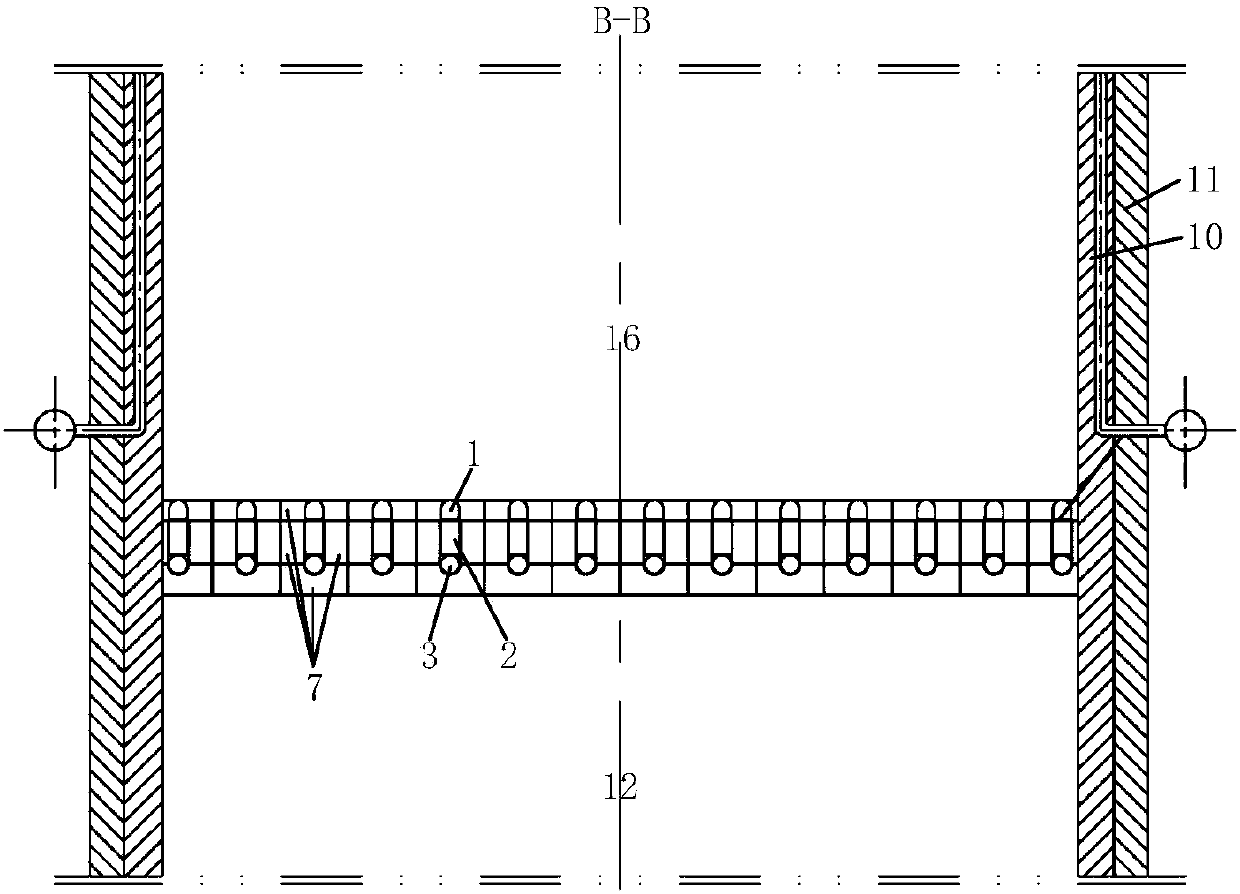

[0025] The main structure of the fluidized bed combustion device involved in this embodiment includes a wind cap 1, an air distribution pipe 2, a cooling air pipe 3, a metal hose 4, an upper air chamber 5, a lower air chamber 6, a movable block brick assembly 7, and thermal insulation cotton 8 , detachable cover plate 9, furnace 16, slag hopper 12, slag discharge pipe 14 and slag discharge door 15, wherein, furnace 16 comprises furnace inner wall 10 and furnace outer wall 11, and the bottom of furnace 16 of columnar and cavity structure is vertically arranged A funnel-shaped slag hopper 12 is provided, and more than one slag hopper small hole 13 is provided on the slope of the slag hopper 12. The lower part of the slag hopper 12 is vertically provided with a slag discharge pipe 14, and the bottom of the slag discharge pipe 14 is provided with a slag discharge door. 15. There are more than three rows of air distribution pipes 2 horizontally below the inner wall 10 of the furnace...

Embodiment 2

[0036] The difference between this embodiment and Embodiment 1 is that the movable block brick assembly is a strip-shaped top movable block brick, two strip-shaped side movable block bricks with the same size and symmetrical structure and a U-shaped bottom The back-type integrated structure composed of movable block bricks reduces the number of components of the movable block brick assembly of a large-scale combustion device, and is convenient for practical application.

[0037] The specific steps of air distribution and slag discharge of the fluidized bed combustion device involved in this embodiment are different from those of Embodiment 1 in that: when adjusting the size of slag discharge in step (4), the single movable block brick assembly 7 is pulled out as a whole .

Embodiment 3

[0039] The difference between this embodiment and Embodiment 2 is that the movable block brick assembly of the integrated structure can be split into a combined structure according to the axis of symmetry or diagonal, according to the use for fluidized bed waste incineration and garbage The type of fuel incinerated in the field of power generation technology and the processing capacity of the combustion device select the corresponding movable block brick assembly, which is convenient for operation and application.

[0040] The specific steps of air distribution and slag discharge of the fluidized bed combustion device involved in this embodiment are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com