Energy-saving dynamic plate ice heat pump

A plate ice and heat pump technology, applied in ice making, ice manufacturing, ice storage/distribution, etc., can solve the problems of low heat transfer efficiency, high configuration cost, uneven cooling and heating of the evaporator, and achieve a stable system cycle process. , The effect of low supporting cost and large ice making capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

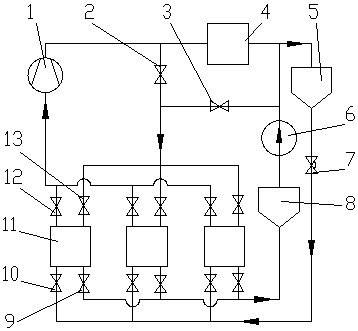

[0008] Example: see figure 1 , an energy-saving dynamic plate ice heat pump, mainly includes a heating main circulation system and a hot gas bypass branch; it also includes connected pipes, valves, and a detection and control system in the system; The heating valve and the ice-melting valve are controlled and switched, and each group of heat exchangers absorbs heat to make ice, and melts and de-ices alternately; one group of heat exchangers melts and de-ices, and the other groups of heat The heating main circulation system has been in continuous heating operation. The evaporator is an inflation evaporator, and the evaporators are divided into multiple groups connected in parallel. Spray on each expansion evaporator, and use valve control to switch. Each group of evaporators absorb heat to make ice, melt ice and de-ice alternately. The evaporator is a heat exchanger made of double-layer aluminum plates. After surface treatment of aluminum plates of a certain specification, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com