Aggregate-adhesive cement weak boundary layer performance test method based on dynamic shear rheological test

A technology of rheological test and weak boundary layer, applied in the direction of applying stable shear force to test material strength, material inspection products, etc., can solve the problem of lack of weak boundary layer performance test of aggregate-glue interface, etc., to achieve test The effect of simple operation, simple test and processing of experimental data, and convenient promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

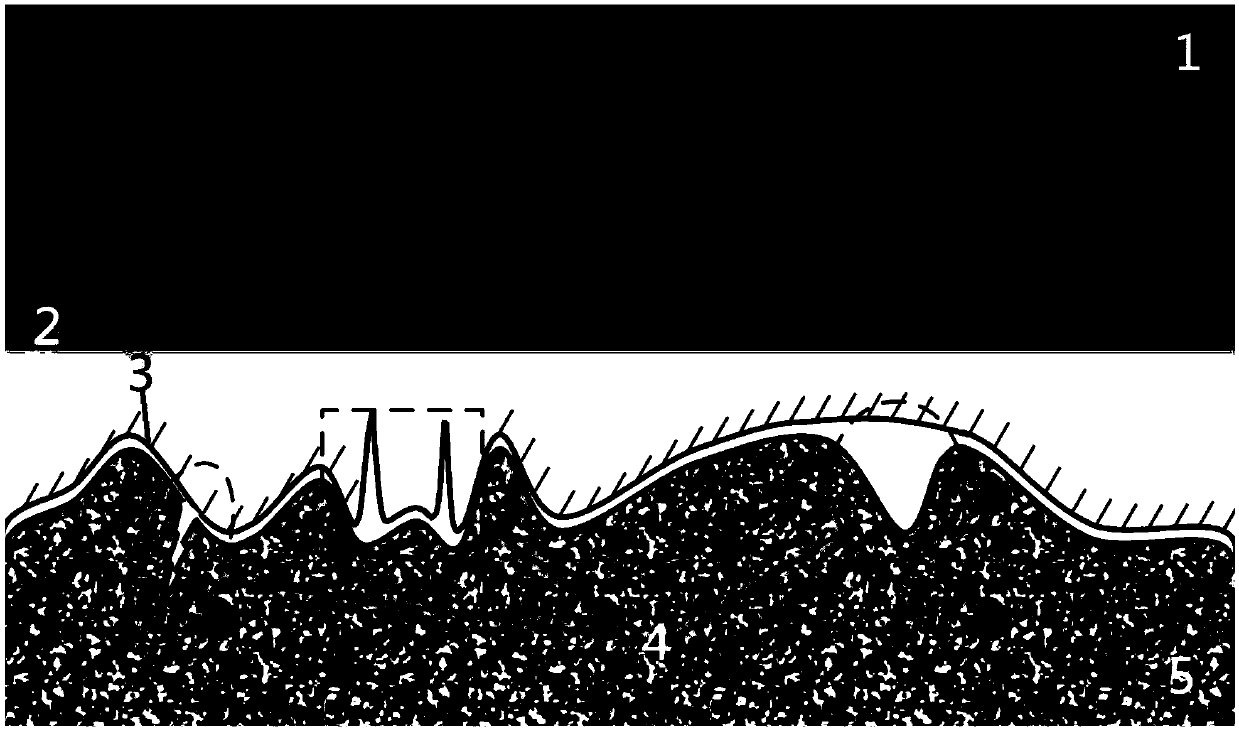

[0038] Specific embodiment one: a kind of aggregate-mucilage weak boundary layer performance test method based on dynamic shear rheological test of the present embodiment is carried out according to the following steps:

[0039] 1. Dry the mineral powder in an oven at a temperature of 100°C to 110°C, then place the dried mineral powder and asphalt in an oven at a temperature of 155°C to 165°C, and heat for 4h to 6h to obtain heating mineral powder and heating bitumen;

[0040] 2. Put the heated asphalt in a constant temperature container with a temperature of 155°C to 165°C, and under the condition of a stirring speed of 350r / min to 450r / min, add the heated mineral powder to the heated asphalt in portions, and stir evenly to obtain asphalt mortar;

[0041] The mass ratio of the heating mineral powder to the heating pitch is (0.8~1.2):1;

[0042] 3. Make the asphalt mortar into a round cake, then dry and cool to obtain the mortar specimen;

[0043] When the test temperature ...

specific Embodiment approach 2

[0070] Embodiment 2: This embodiment is different from Embodiment 1 in that: the volatile organic solvent described in step 6 is gasoline or petroleum ether; the volatile organic solvent described in step 10 is gasoline or petroleum ether. Others are the same as in the first embodiment.

specific Embodiment approach 3

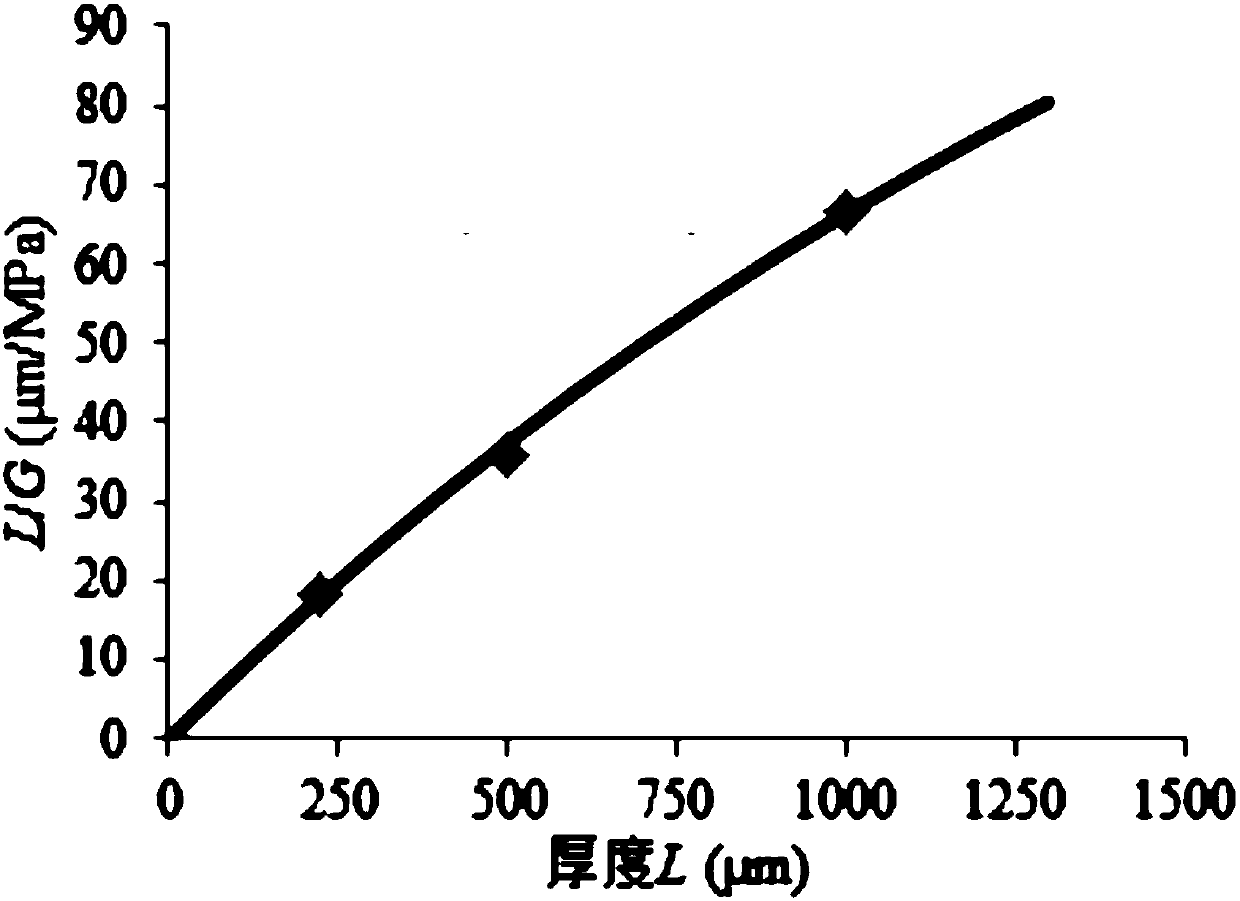

[0071] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step ten, the test condition is set for the dynamic shear rheometer, specifically, the control mode of the dynamic shear rheological test is set as the strain control mode, The applied dynamic strain amplitude is 0.25%, and the loading frequency is 10Hz. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com