Nano silicon-carbon composite anode material for lithium ion batteries, and preparation method of nano silicon-carbon composite anode material

A technology of lithium-ion batteries and negative electrode materials, applied in the direction of battery electrodes, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of poor charge and discharge efficiency and cycle performance of silicon materials, low conductivity, and solid electrolyte membranes. Instability and other problems, achieve good Coulombic efficiency and cycle performance, solve the expansion problem, and have good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

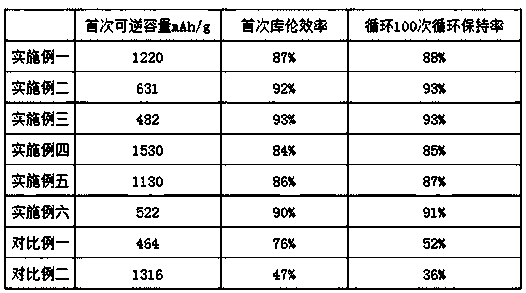

Examples

Embodiment 1

[0025] 1) First, put 350g of nanocrystalline graphite particles with a particle size D50 of 10nm into a vacuum rotary tube furnace and then perform vacuum treatment; then heat the vacuum rotary tube furnace to 800°C at a speed of 1.8L / min. The silicon source introduced into the vacuum rotary tube furnace decomposes the silicon source into nano-silicon with a particle size of 5-100nm, and the nano-silicon is uniformly coated on the nanocrystalline graphite particles with a shell structure. The amount of deposited silicon reached 525g, and the first precursor was obtained after cooling. Silicon source is SiH 4 、Si 2 h 4 、SiH 3 Cl, SiH 2 Cl 2 , SiHCl 3 and SiCl 4 one or any combination of them.

[0026] 2), firstly mix 875g of the first precursor prepared in step 1) and 875g of carbonaceous binder uniformly in a mixer for 0.8 hours to prepare the mixture of the first precursor and carbonaceous binder, carbonaceous binder It is one or any combination of sucrose, glucose,...

Embodiment 2

[0030] 1) First, put 500g of nanocrystalline graphite particles with a particle size D50 of 50nm into a vacuum rotary tube furnace and then perform vacuum treatment; then heat the vacuum rotary tube furnace to 850°C and pump it at a speed of 1.8L / min. The silicon source introduced into the vacuum rotary tube furnace decomposes the silicon source into nano-silicon with a particle size of 5-100nm, and the nano-silicon is uniformly coated on the nanocrystalline graphite particles with a shell structure. The amount of deposited silicon reached 62.5g, and the first precursor was obtained after cooling. Silicon source is SiH 4 、Si 2 h 4 、SiH 3 Cl, SiH 2 Cl 2 , SiHCl 3 and SiCl 4 one or any combination of them.

[0031] 2), first, 562.5g of the first precursor prepared in step 1) and 62.5g of carbonaceous binder were uniformly mixed in a mixer for 0.9 hours to prepare a mixture of the first precursor and carbonaceous binder, and the carbonaceous binder The binder is one or ...

Embodiment 3

[0035] 1) First, put 500g of nanocrystalline graphite particles with a particle size D50 of 200nm into a vacuum rotary tube furnace and then perform vacuum treatment; then heat the vacuum rotary tube furnace to 900°C and pump it at a speed of 1.9L / min. The silicon source introduced into the vacuum rotary tube furnace decomposes the silicon source into nano-silicon with a particle size of 5-100nm, and the nano-silicon is uniformly coated on the nanocrystalline graphite particles with a shell structure. The amount of deposited silicon reaches 100 g, and the first precursor is obtained after cooling. Silicon source is SiH 4 、Si 2 h 4 、SiH 3 Cl, SiH 2 Cl 2 , SiHCl 3 and SiCl 4 one or any combination of them.

[0036] 2) First, mix 600g of the first precursor prepared in step 1) and 1400g of carbonaceous binder uniformly in a mixer for 0.9 hours to prepare a mixture of the first precursor and carbonaceous binder, carbonaceous binder It is one or any combination of sucrose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com